Luggage and surface layer processing technology thereof

A surface treatment, luggage technology, applied in the direction of pretreatment surface, coating, luggage, etc., can solve problems such as dull color of luggage, and achieve the effect of excellent wear resistance, transparent surface, good high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

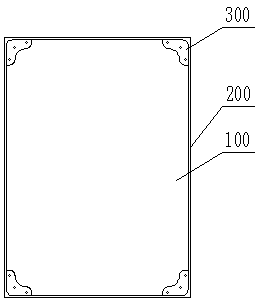

[0034] Example 1, please refer to Figure 1-4 , luggage, including a box body, the box is at least provided with a casing 100, a primer layer 400 on the surface of the casing 100, an electroplating layer 500 on the surface of the primer, and a topcoat on the surface of the electroplating layer 500 from the inside to the outside. Layer 600.

[0035] Further, the luggage case 100 is made of PC or ABS or a mixture of the two, and also includes a pure aluminum luggage case and a PP luggage case.

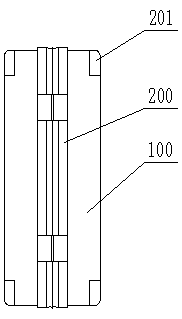

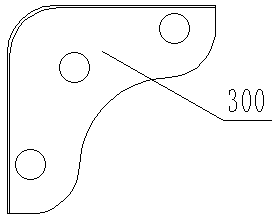

[0036] Further, the luggage case 100 is reinforced with an aluminum alloy frame 200 , and the four corners of the case 100 are treated with aluminum alloy corners 300 .

[0037] A surface treatment process for luggage, comprising the following steps:

[0038] S1. Inspection of incoming materials. Check the processed shell 100 to see if it is damaged or scratched. If it is qualified, it will enter the next process, and if it is unqualified, it will be repaired;

[0039] S2, install the...

Embodiment 2

[0049] Embodiment 2. The difference between this embodiment and Embodiment 1 is that in step S3, the housing 100 is decontaminated by impregnation treatment, the impregnation solution is 20-30% degreasing agent, the temperature is controlled at 40-50°, and the impregnation time is controlled at 20-30min.

[0050] Specifically, the degreasing agent adopts decontamination oil.

Embodiment 3

[0051] Embodiment 3, the difference between this embodiment and Embodiment 2 is that the metal film layer in the step S6 is one of the metal aluminum layer, the metal copper layer, the metal nickel layer and the metal chromium layer, wherein the preferred metal film layer is Metallic aluminum layer.

[0052] The inspection items are mainly divided into appearance and paint film hardness;

[0053] Appearance Inspection Results Form

[0054] Example 1 Embodiment two Embodiment Three integral 29 30 30

[0055]Appearance inspection passing standards: the surface of the product is uniform in color and has no obvious color difference; grains, orange peel bubbles and obvious scratches; and the appearance inspection adopts piece-by-piece inspection, wherein 30 pieces from each of the three examples are randomly selected for the appearance inspection, and 1 point is scored for passing, and 0 points for failing.

[0056] That is, the three embodiments of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com