Degradable two-color mulching film

A two-color mulch, silver-colored technology, applied in plant protection, application, climate change adaptation, etc., can solve the problems of not having two-color mulch, affecting crop growth, destroying soil structure, etc., to increase the intensity of photosynthesis, good promotion prospects, increase The effect of soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] inner layer:

[0032] PBAT: 68%, PLA: 26%, black masterbatch 4%, PPA masterbatch 2%;

[0033] Middle:

[0034] PBAT: 62%, PLA: 35%, black masterbatch 1%, PPA masterbatch 2%;

[0035] Outer layer:

[0036] PBAT: 64%, PLA: 29%, silver masterbatch 4%, PPA masterbatch 3%;

[0037] The PBAT is a fully biodegradable material produced by Guangzhou Jinfa Company, the PLA is a degradable material produced by BASF, and the black or silver masterbatch is a color masterbatch prepared with PBAT as the main base material.

[0038] According to the above formula, after the outer layer, middle layer and inner layer formula are measured, they are mixed evenly, respectively added to the hopper, melted and extruded through a multi-layer co-extruder, and the melting temperature is set at 170 ° C, and then enters the annular co-extrusion die The three-layer film is extruded from the die head, and the compressed air is blown in from the cooling air duct in the center of the die head to b...

Embodiment 2

[0040] inner layer:

[0041] PBAT: 60%, PLA: 35%, black masterbatch 4%, PPA masterbatch 1%;

[0042] Middle:

[0043] PBAT: 60%, PLA: 35%, black masterbatch 2%, PPA masterbatch 3%;

[0044] Outer layer:

[0045] PBAT: 60%, PLA: 35%, silver masterbatch 4%, PPA masterbatch 1%;

[0046] The PBAT is a fully biodegradable material produced by Guangzhou Jinfa Company, the PLA is a degradable material produced by BASF, and the black or silver masterbatch is a color masterbatch prepared with PBAT as the main base material.

[0047] According to the above formula, after the outer layer, middle layer and inner layer formula are measured, they are mixed evenly, respectively added to the hopper, melted and extruded through a multi-layer co-extruder, the melting temperature is set at 175 ° C, and then enters the ring co-extrusion die The three-layer film is extruded from the die head, and the compressed air is blown in from the cooling air duct in the center of the die head to blow the...

Embodiment 3

[0049] inner layer:

[0050] PBAT: 60%, PLA: 34%, black masterbatch 3%, PPA masterbatch 3%;

[0051] Middle:

[0052] PBAT: 63%, PLA: 33%, black masterbatch 2%, PPA masterbatch 2%;

[0053] Outer layer:

[0054] PBAT: 68%, PLA: 26%, silver masterbatch 4%, PPA masterbatch 2%;

[0055] The preparation process is the same as in Example 2.

[0056] The indicators of the degradable two-color mulch film prepared in Example 1-3 were tested with reference to the GB13735-2017 polyethylene blown agricultural ground cover film standard. After testing, all indicators were better than the national standard. The test results are shown in Table 1, Table 2, table 3.

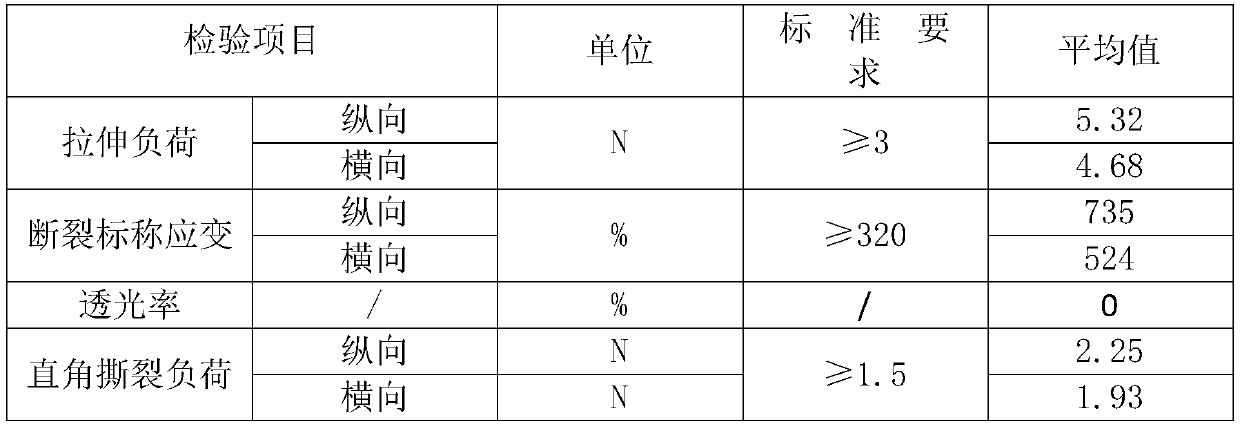

[0057] Table 1

[0058]

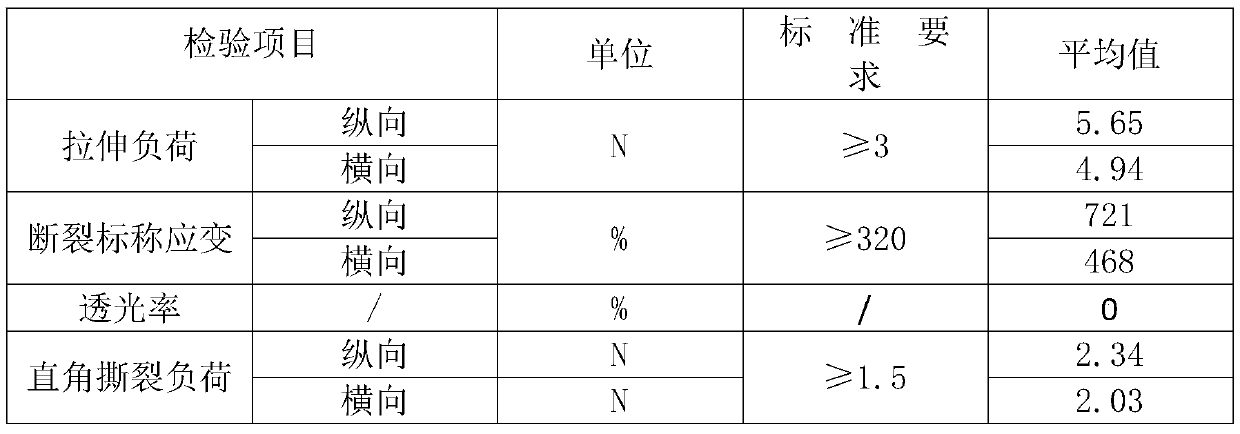

[0059] Table 2

[0060]

[0061] table 3

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com