High strength galvanized steel sheet and production method therefor

A technology of galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, chemical instruments and methods, hot-dip coating process, etc., can solve problems such as delayed fracture, and achieve improved resistance to delayed fracture, high performance of automobile body, high The effect of strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0110] Manufacture of steel plates for evaluation

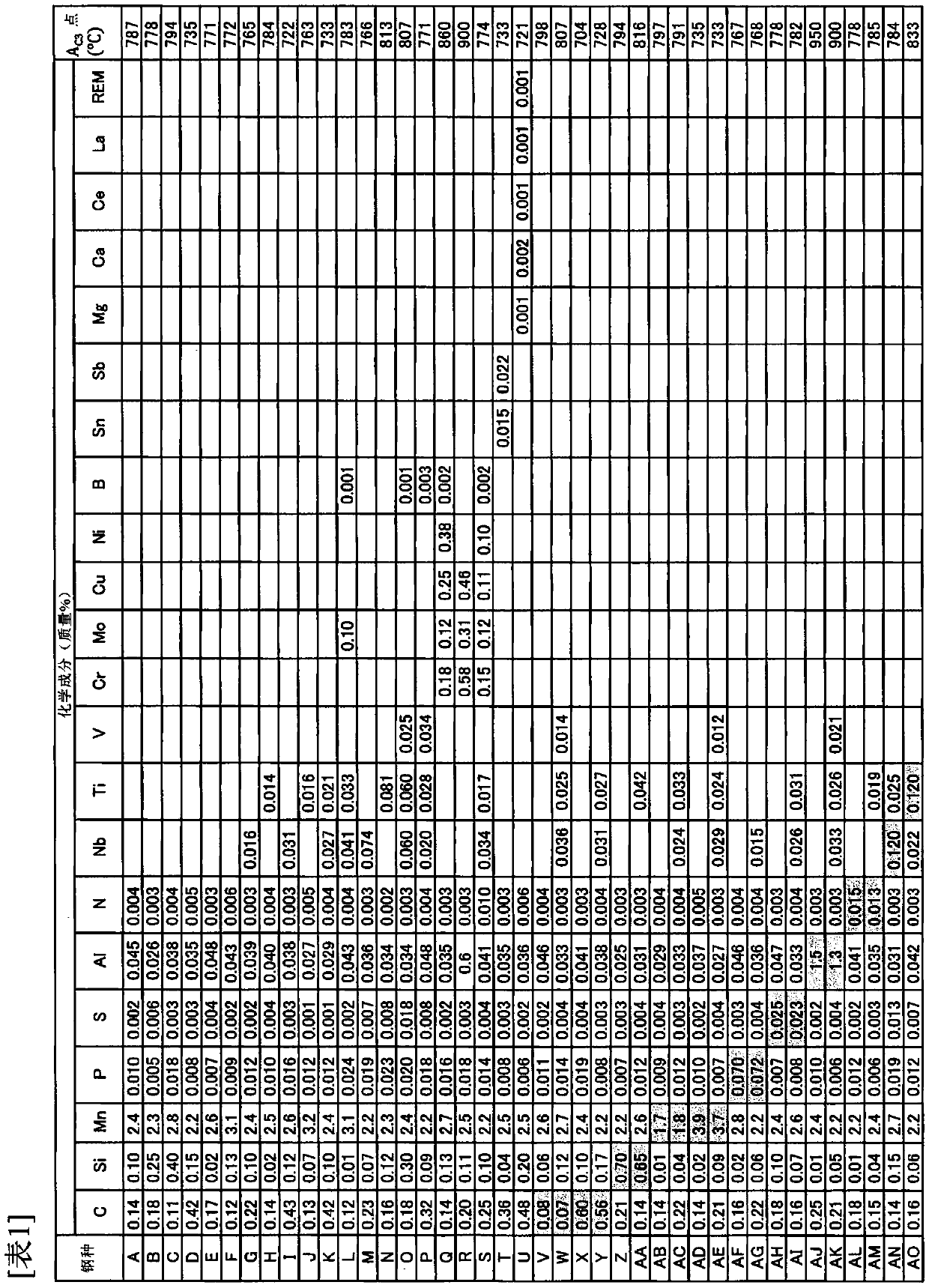

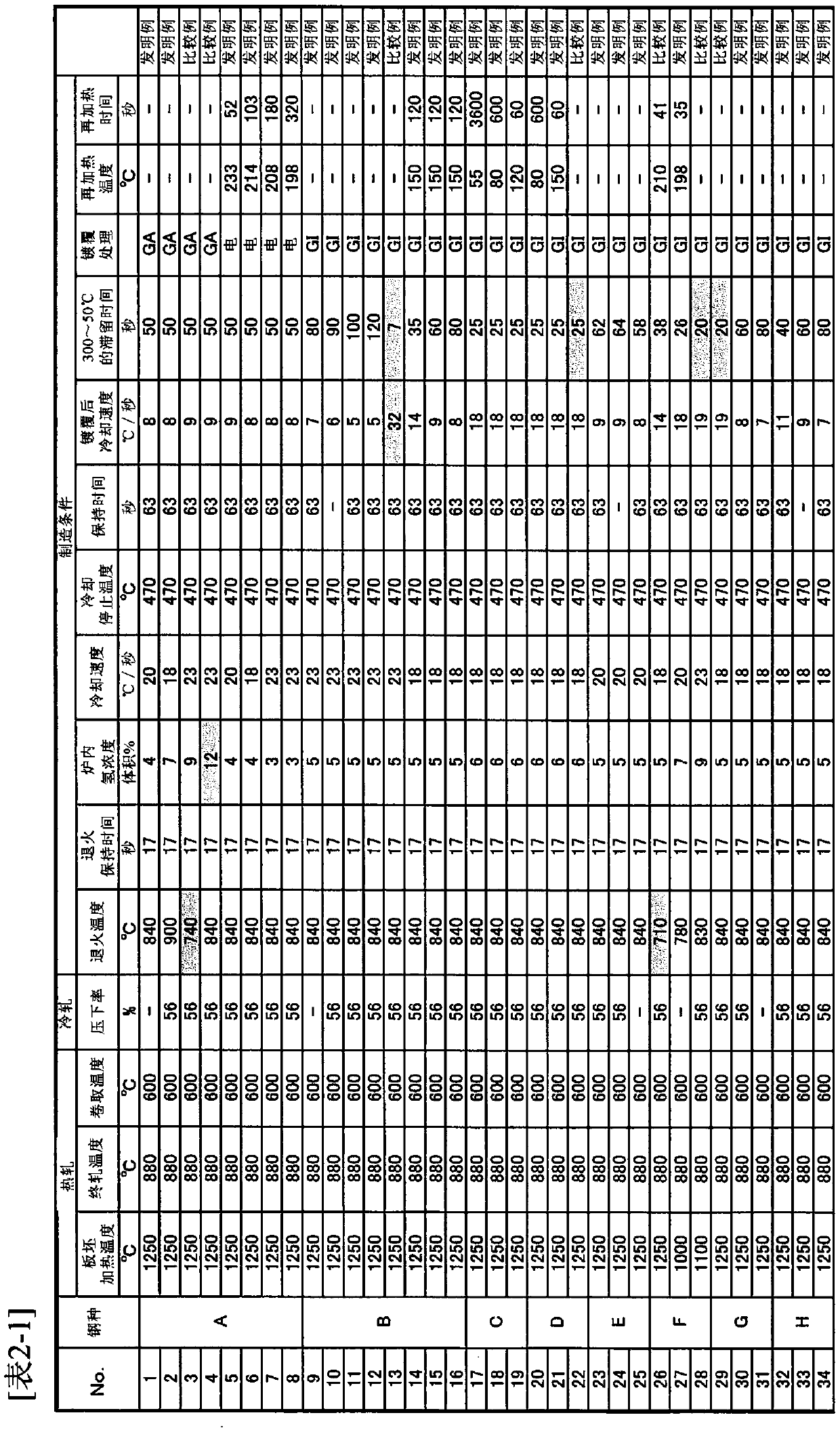

[0111] Steel having the composition shown in Table 1 and the remainder consisting of Fe and unavoidable impurities was melted in a vacuum melting furnace, and then billet-rolled to obtain a billet-rolled material with a thickness of 27 mm. The obtained slab-rolled material was hot-rolled to a plate thickness of 4.0 to 2.8 mm. Hot rolling was carried out under the conditions shown in Table 2 by setting the slab heating temperature to a temperature of 1000°C to 1250°C. Next, for the sample subjected to cold rolling, the hot-rolled steel sheet was ground to a thickness of 3.2 mm, and then cold-rolled to a thickness of 2.5 to 1.4 mm to manufacture a cold-rolled steel sheet. Next, the hot-rolled steel sheets or cold-rolled steel sheets obtained above were heat-treated under the conditions shown in Table 2 to manufacture galvanized steel sheets.

[0112] The alloyed hot-dip galvanized steel sheet is manufactured at an alloying te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com