Flux for Submerged Arc Welding

A submerged arc welding and flux technology, applied in arc welding equipment, welding equipment, welding medium, etc., can solve the problems of slag barrier effect, specific surface area reduction, welding metal toughness deterioration, etc., to achieve good welding operability, reduce Effect of diffusible hydrogen amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, modes for implementing the present invention will be described in detail. In addition, this invention is not limited to embodiment described below.

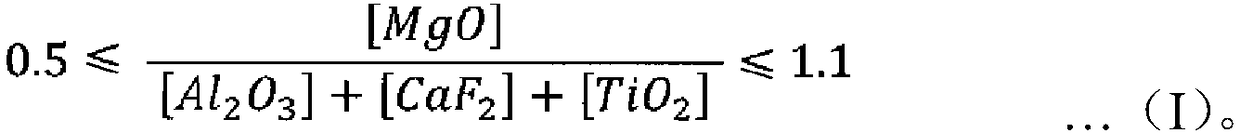

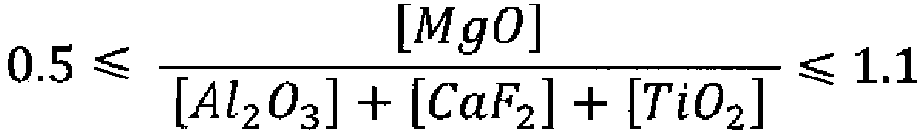

[0024] In order to solve the above-mentioned problems, the inventors of the present invention conducted earnest experimental studies, and as a result, they came to the conclusions shown below. When using a DC welding power source, in order to maintain good slag stripping properties, the SiO content of the flux should be reduced as much as possible. 2 quantity. In addition, as long as the amount of MgO added is not increased compared with the flux described in Patent Document 5, the slag detachability cannot be improved.

[0025] Therefore, in the flux for submerged arc welding (hereinafter, simply referred to as flux.) according to the embodiment of the present invention, SiO 2 The content is 10-20% by mass, the MgO content is 25-35% by mass, and the water-soluble SiO 2 It is limited to 1% by mass or less....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com