Preparation method of nano-sheet Sb/C composite material for lithium ion/sodium ion battery anode

A sodium-ion battery, nanosheet technology, applied in nanotechnology for materials and surface science, battery electrodes, negative electrodes, etc., can solve the problems of slow ion and electron movement, poor material rate performance, etc. The effect of reliable production of product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

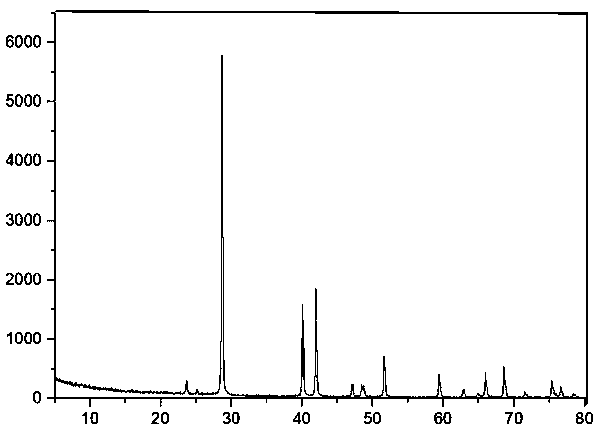

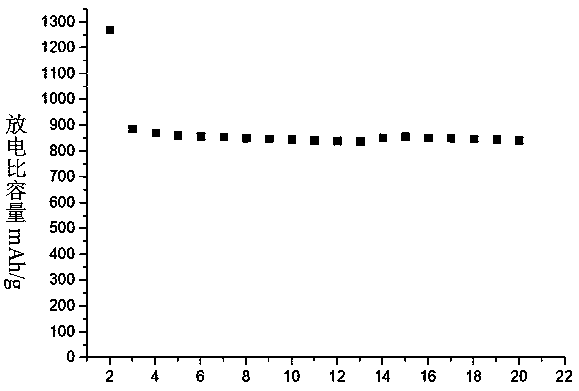

Embodiment 1

[0029] antimony salt SbCl 3 and the ligand 2-methylimidazole were dissolved in the solvent methanol respectively to obtain a concentration of 0.05mg / mL antimony salt solution and a concentration of 20mg / mL ligand solution, the antimony salt solution and the ligand solution in a volume ratio of 3:1 Mix and continue to stir and react at 25°C for 3h. After the reaction, age for 18h, wash with methanol for 3 times, and dry at 60°C to obtain a nano-flaky Sb precursor; disperse the obtained nano-flaky Sb precursor in ethanol and water A dispersion solution with a concentration of 10 mg / mL was formed in the mixed solution, and then resorcinol, formaldehyde, CTAB and ammonium hydroxide were added to carry out carbon coating, and the reaction was continuously stirred for 3 hours. After the reaction, it was aged for 18 hours and washed with ethanol for 3 hours. The nanosheet-like Sb / C precursor was obtained after drying at 60°C; the obtained nanosheet-like Sb / C precursor was heated at a...

Embodiment 2

[0032] The antimony salt Sb(NO 3 ) 3 and the ligand cis 1,3-dimethylimidazole were dissolved in solvent methanol respectively to obtain a concentration of 0.1mg / mL antimony salt solution and a concentration of 10mg / mL ligand solution, antimony salt solution and ligand solution by volume Mix at a ratio of 3:1 and continue to stir and react at 25°C for 12h. After the reaction is completed, it is aged for 18h, centrifuged with methanol for 3 times, and dried at 60°C to obtain a nano-sheet Sb precursor; the obtained nano-sheet Sb precursor is dispersed Form a dispersion with a concentration of 10 mg / mL in a mixed solution of ethanol and water, then add resorcinol, formaldehyde, CTAB and ammonium hydroxide for carbon coating, continue stirring for 3 hours, and age for 18 hours after the reaction. The nanosheet-like Sb / C precursor was obtained after centrifuged washing with ethanol for 3 times and drying at 60 °C; the obtained nanosheet-like Sb / C precursor was heated at 1 °C / The ...

Embodiment 3

[0035] antimony salt Sb 2 (SO 4 ) 3 and the ligand 4,4-bipyridine were dissolved in the solvent methanol respectively to obtain an antimony salt solution with a concentration of 1 mg / mL and a ligand solution with a concentration of 4 mg / mL. The antimony salt solution and the ligand solution were mixed in a volume ratio of 3:1 Mix and continue to stir and react at 25°C for 2h. After the reaction, age for 18h, wash with methanol for 3 times, and dry at 60°C to obtain a nano-sheet Sb precursor; disperse the obtained nano-sheet Sb precursor in ethanol and water A dispersion solution with a concentration of 10mg / mL was formed in the mixed solution, and then resorcinol, formaldehyde, CTAB and ammonium hydroxide were added to carry out carbon coating, and the reaction was continuously stirred for 3 hours. After drying at 60°C, the nanosheet-like Sb / C precursor was obtained; the obtained nanosheet-like Sb / C precursor was heated at a rate of 5°C / min to Calcined at 600°C for 8h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com