Tab having special-shaped tab film, preparation method thereof and lithium ion battery

A lithium-ion battery and electrode ear glue technology, which is applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of battery safety risks, increased hardness of side sealing edges, and core extrusion, and achieves high accuracy. High, improve package reliability, precise die-cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

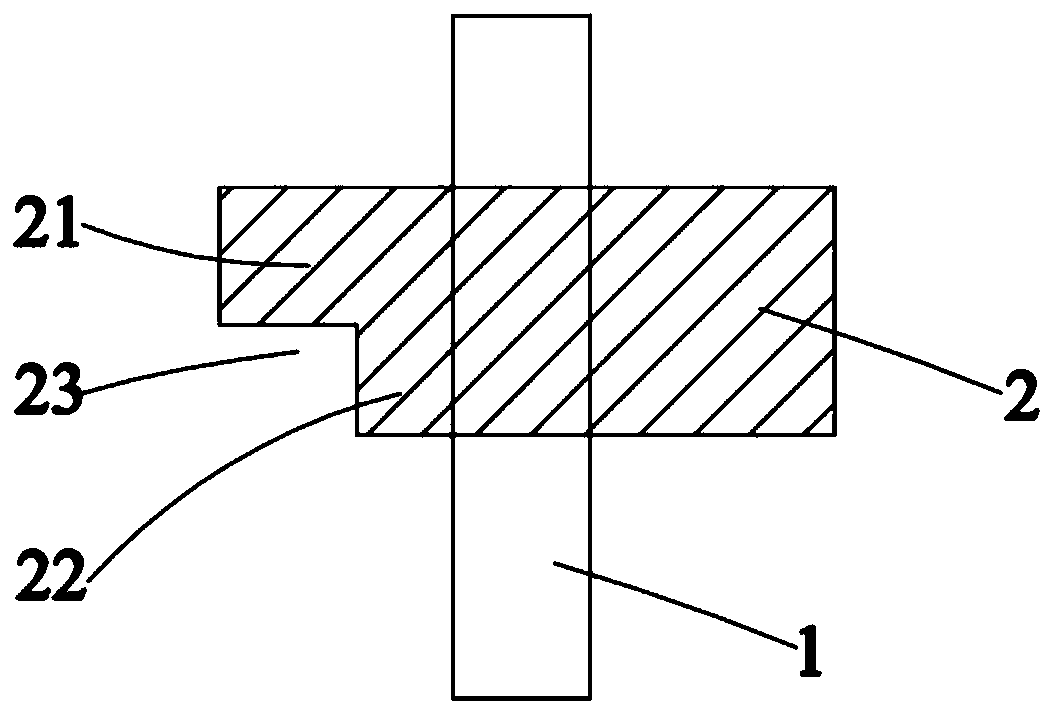

[0038] Such as figure 1 As shown, a tab with special-shaped tab glue includes a metal strip 1 and special-shaped tab glue 2 symmetrically arranged on both surfaces of the metal strip 1. The special-shaped tab glue 2 includes an integrally formed first colloid part 21 and a second Two colloidal parts 22, the length of the first colloidal part 21 is greater than the length of the second colloidal part 22, the first colloidal part 21 and the second colloidal part 22 both have an end aligned setting, the first colloidal part 21 and the second colloidal part A gap 23 is formed between the 22. The metal strip 1 includes any one of nickel strip, aluminum strip, copper strip and aluminum-nickel strip.

[0039] The preparation method of the tab with special-shaped tab glue in this embodiment includes the following steps:

[0040] 1) Unwind N metal strips first, then position the N metal strips, and then preheat the N metal strips;

[0041] 2) Attach the square ear glue to the two si...

Embodiment 2

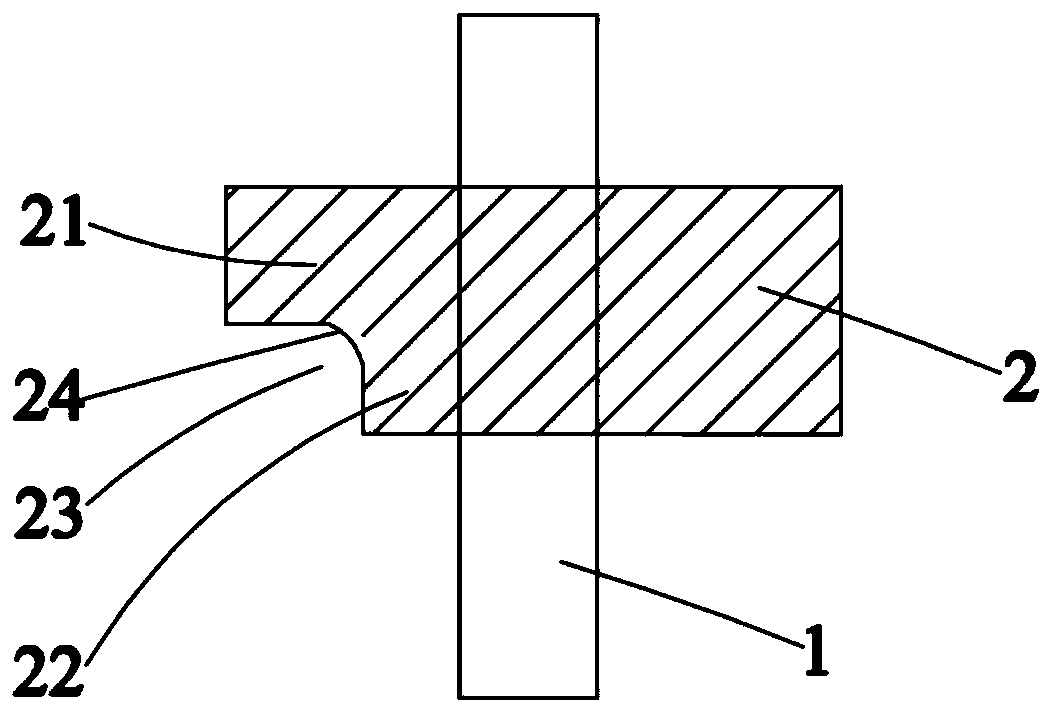

[0046] Such as figure 2 As shown, the difference from Embodiment 1 is that in this embodiment, a rounded corner structure 24 is provided at the transition connection between the first glue part 21 and the second glue part 22 of the special-shaped tab glue.

[0047] In the method for preparing a tab with special-shaped tab glue in this embodiment, in step 4), while the notch is obtained by die-cutting, the inner corner where the notch is located is also rounded. That is, a rounded corner structure is formed at the transition connection between the first colloidal part and the second colloidal part.

[0048] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

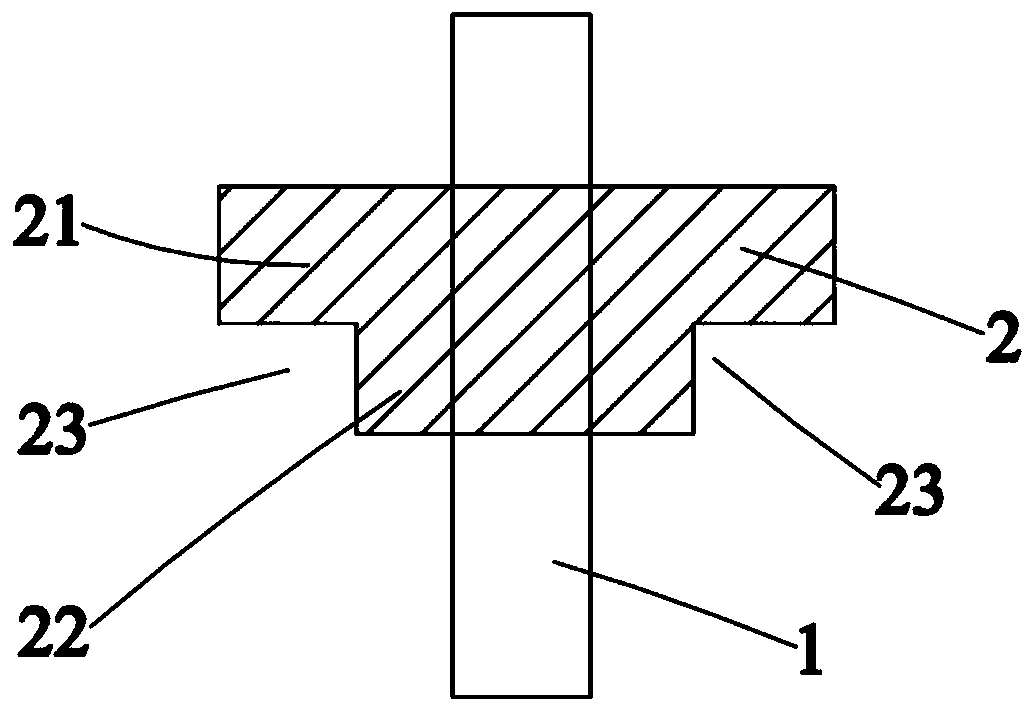

[0050] Such as image 3 As shown, a tab with special-shaped tab glue includes a metal strip 1 and special-shaped tab glue 2 symmetrically arranged on both surfaces of the metal strip 1. The special-shaped tab glue 2 includes an integrally formed first colloid part 21 and a second Two colloid parts 22, the length of the first colloid part 21 is greater than the length of the second colloid part 22, the centers of the first colloid part 21 and the second colloid part 22 are on the same straight line, the first colloid part 21 and the second colloid part Two notches 23 are formed between the portions 22 . The metal strip 1 includes any one of nickel strip, aluminum strip, copper strip and aluminum-nickel strip.

[0051] The preparation method of the tab with special-shaped tab glue in this embodiment includes the following steps:

[0052] 1) Unwind N metal strips first, then position the N metal strips, and then preheat the N metal strips;

[0053] 2) Attach the square ear glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com