A test device for flow and heat transfer characteristics of a transverse non-uniform indirect heating rectangular channel

A rectangular channel and test device technology, used in fluid dynamics tests, measurement devices, material thermal development, etc., can solve the problems of inability to simulate flow heat transfer characteristics, and achieve a simple structure that avoids rapid changes in flow patterns and is easy to process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in detail:

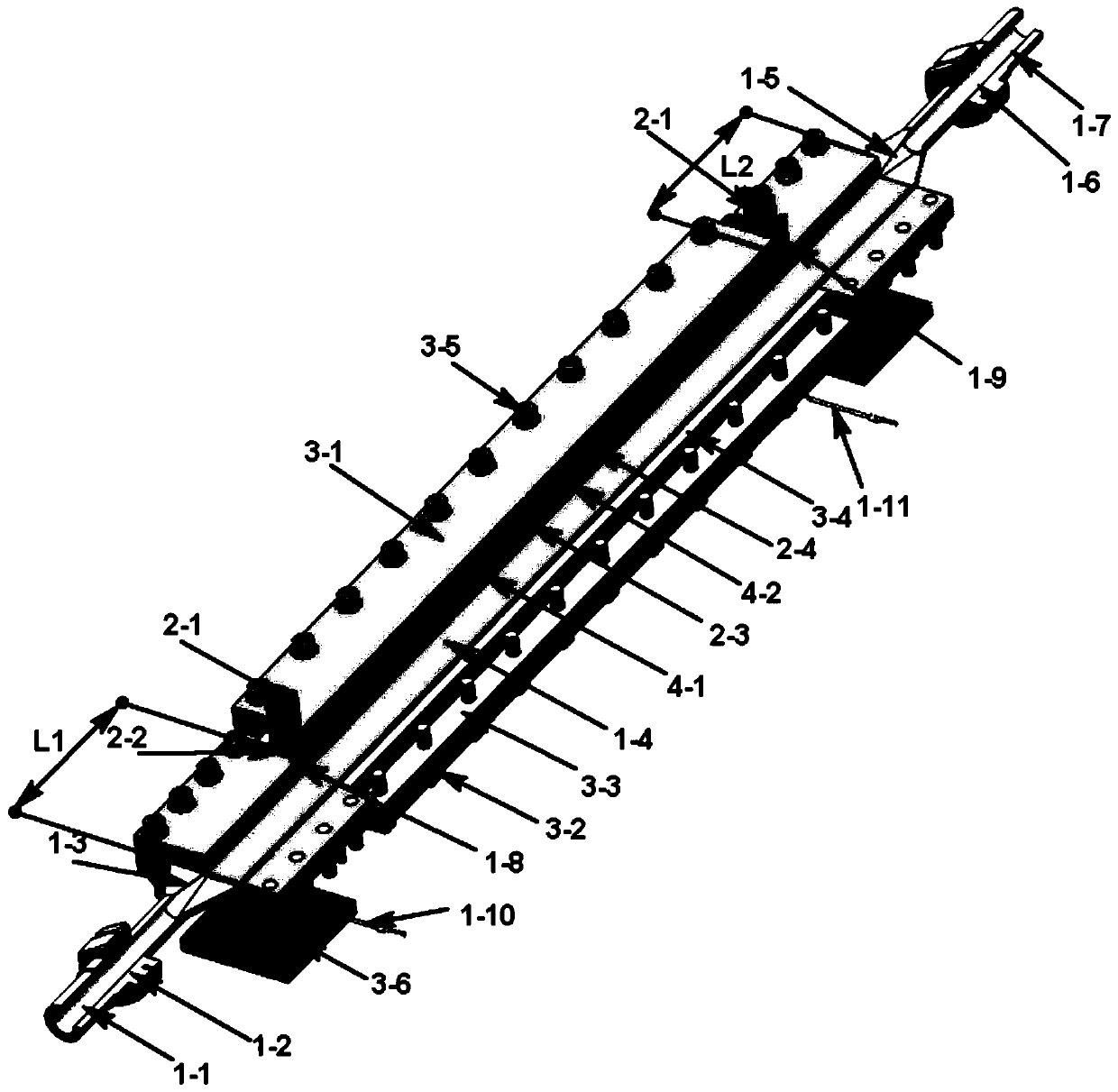

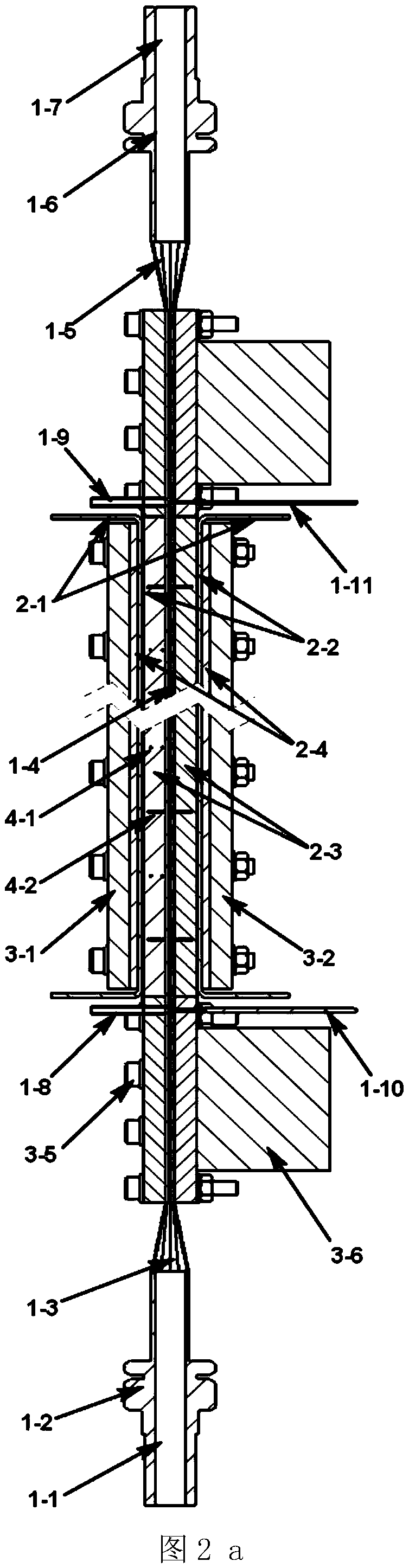

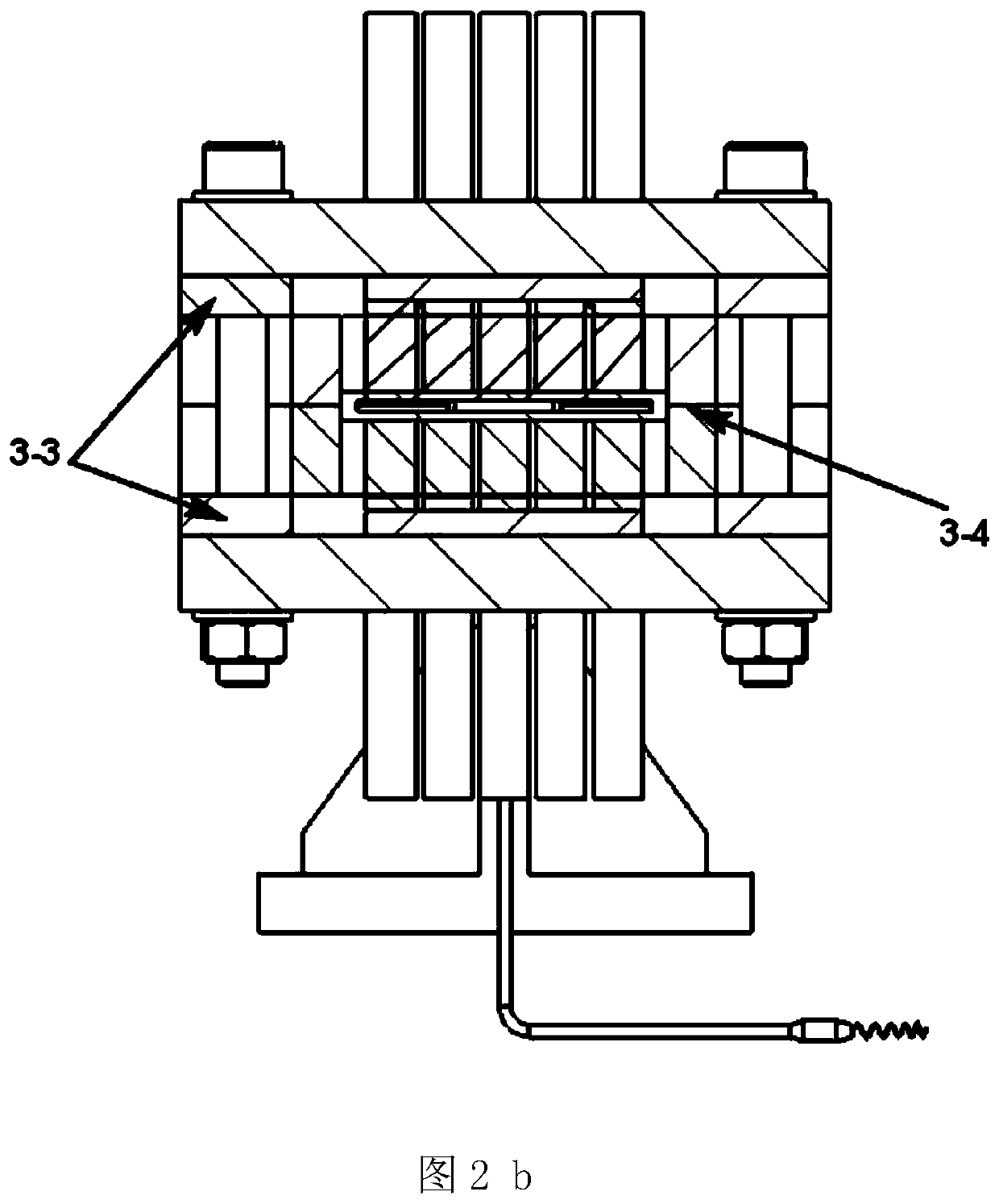

[0034] Such as figure 1 with figure 2 middle figure 2 a. figure 2 As shown in b, the present invention is a test device for flow and heat transfer characteristics of a transverse non-uniform indirect heating rectangular channel. The flow channel body module consists of cylindrical inlet adapter 1-1, inlet ferrule 1-2, inlet shrinkage adapter 1-3, rectangular flow channel unit 1-4, outlet expansion adapter 1-5, and outlet ferrule 1-6 It is composed of a cylindrical outlet connecting pipe 1-7, wherein the inlet ferrule 1-2 is threaded and sealed with the cylindrical inlet connecting pipe 1-1 and the inlet reducing pipe 1-3 respectively; similarly, the outlet ferrule 1-6 is respectively It is threaded and sealed with the cylindrical outlet connecting pipe 1-7 and the outlet expanding diameter connecting pipe 1-5, and the inlet reducing diameter connecting pipe 1-3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com