Method for testing multiple welding residual stress components via three-dimensional optical contour method

A residual stress, three-dimensional optical technology, applied in the direction of measuring force components, measuring devices, force/torque/work measuring instruments, etc., can solve problems such as time-consuming, thick plate welding stress residual stress, limited large-size components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

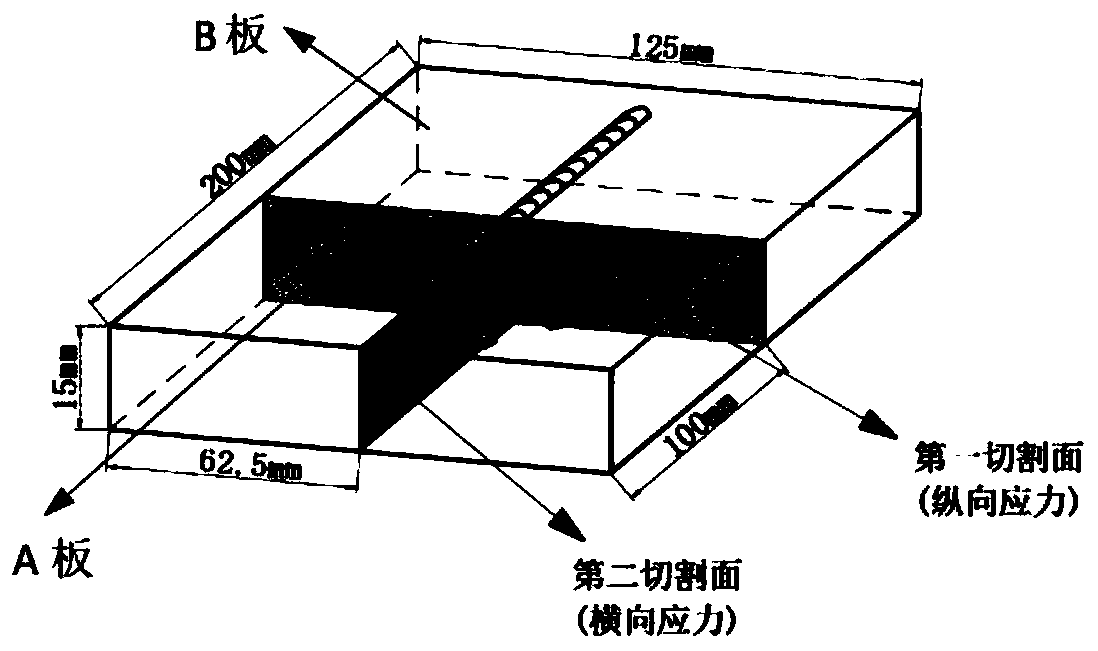

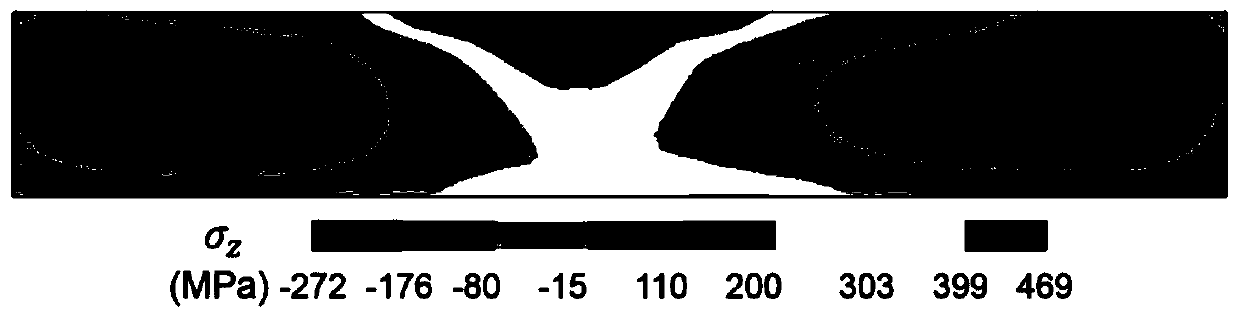

[0056] In this embodiment, Q345 low-carbon steel is selected for the experiment, and ordinary tungsten inert gas welding (TIG) is used. The size of the Q345 test plate is 200mm*125mm*15mm. The weld is located in the center of the test plate, starting from 40mm from one end of the test plate, the length of the weld is 120mm, and the actual width of the weld is about 10mm. Consider performing stress-relief annealing treatment on the test plate. The process parameters of stress-relief annealing are holding temperature 590°C and heating rate 100°C·h -1 , The cooling method is furnace cold, and the holding time is 3h. Welding process parameters: welding current 230A, welding voltage 17.5V, shielding gas 15L min -1 , welding speed 15cm·min -1 .

[0057] A method for testing multiple welding residual stress components by three-dimensional optical profilometry, the steps of which are as follows:

[0058] Step 1: Before welding, perform stress relief annealing on the test plate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com