Transmission device capable of eliminating transmission clearance and clearance eliminating method thereof

A technology of speed change and clearance, applied in hoisting devices, portable lifting devices, components with teeth, etc., can solve the problems of difficult transmission accuracy, many transmission components, complex structure, etc., to reduce wear and improve accuracy. Longevity and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment discloses a speed change device, which can also be a speed change device that can eliminate transmission gaps, and the device can be realized by the device of the present invention and / or other replaceable components. For example, the device of the present invention is realized by using various components in the device of the present invention. The entire and / or partial contents of the preferred implementations of other embodiments may be used as supplements to this embodiment unless conflicts or contradictions are caused.

Embodiment approach

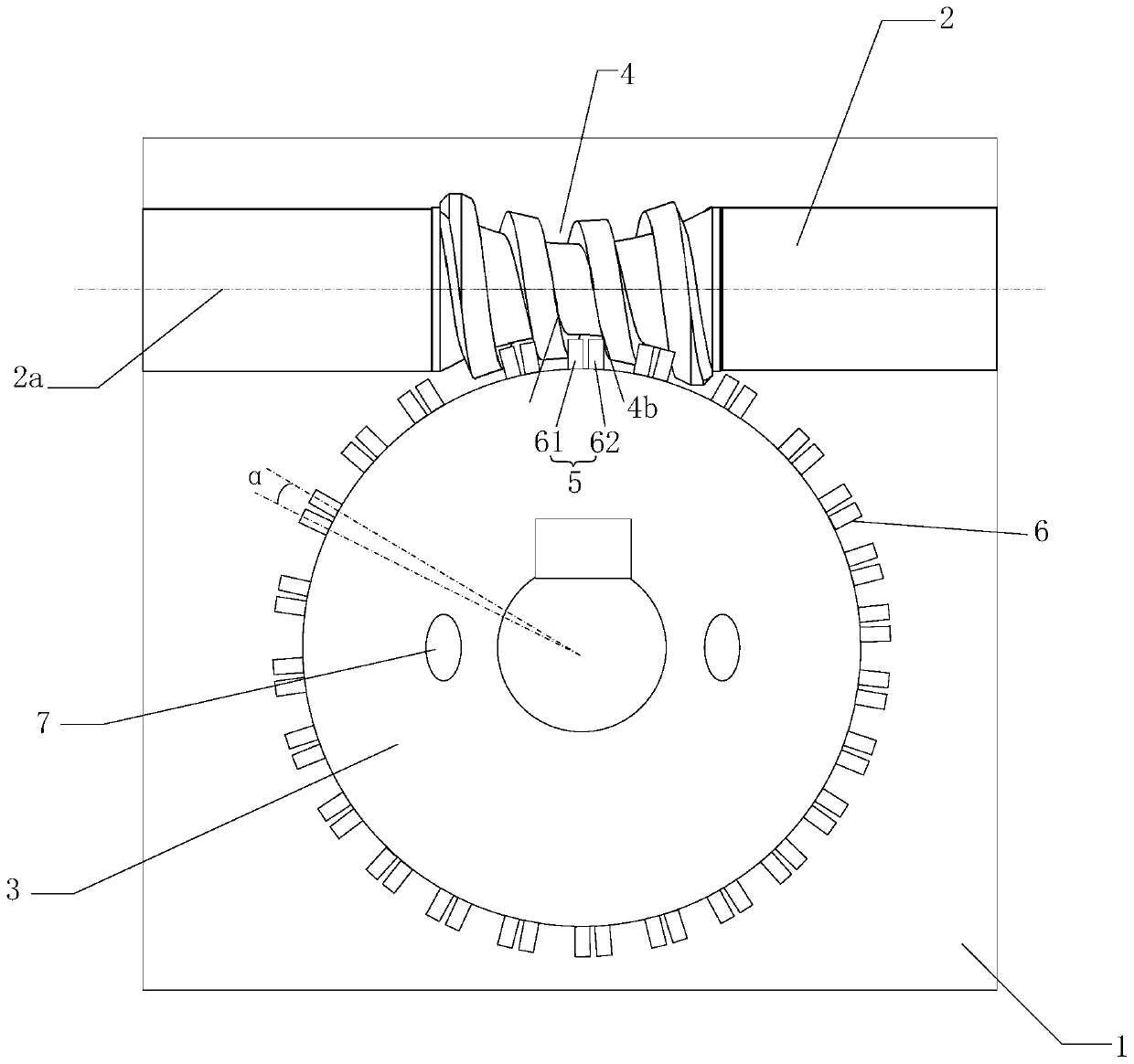

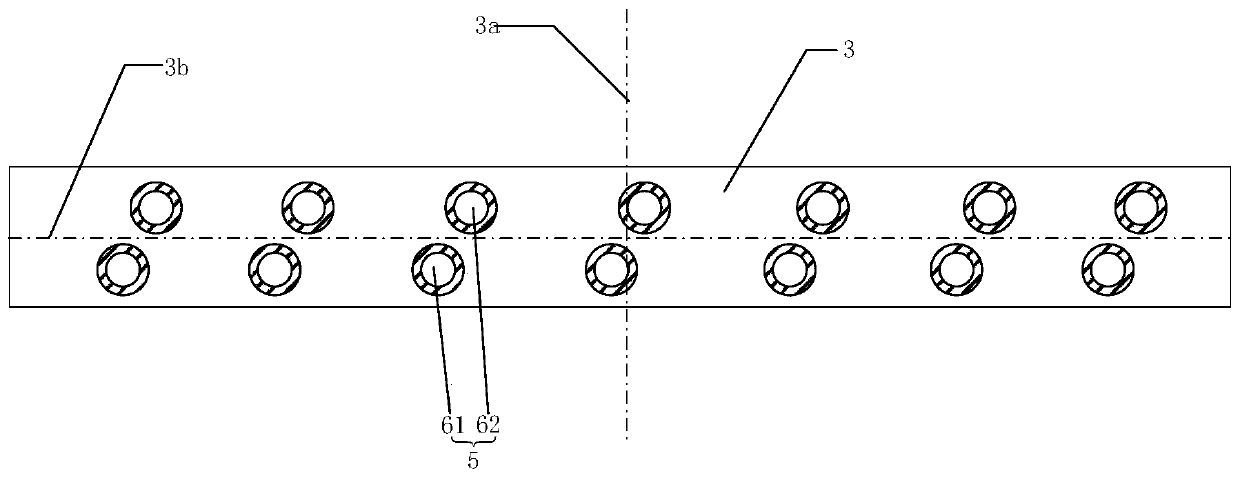

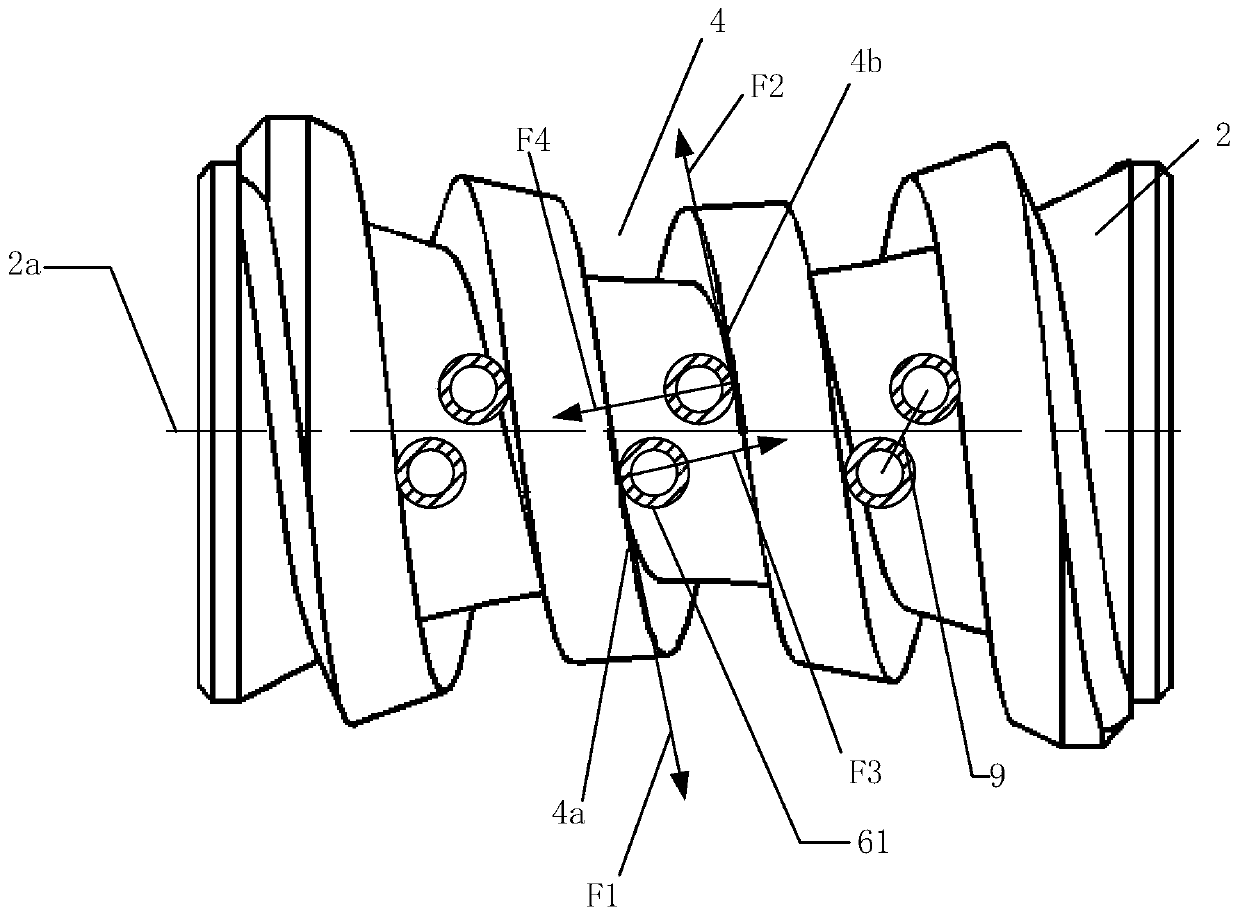

[0055] According to a preferred embodiment, a speed change device capable of eliminating transmission backlash at least includes a worm 2 and a worm wheel 3 arranged in a casing 1 with axes different from each other. Preferably, as figure 1 As shown, the box body 1 is provided with at least two openings, one opening is located at one axial end of the worm 1 , and is used for connecting devices such as servo drives to the worm 1 . The worm wheel 2 is also provided with an opening at one axial end thereof, and the opening is used for connecting with a shaft coupling. Preferably, the axes are out of plane means that the worm axis 3a and the worm axis 2a are out-of-plane straight lines, the worm axis 2a and the worm axis 3a are not on the same plane, neither intersecting nor parallel. Preferably, the worm axis 2a and the worm wheel axis 3a are orthogonal to each other. Through this arrangement, the friction between the worm gear 5 and the wormway 4 can be reduced, and a larger t...

Embodiment 2

[0066] This embodiment discloses a speed change device, which can be realized by the device of the present invention and / or other replaceable components. For example, the device of the present invention is realized by using various components in the device of the present invention. The entire and / or partial contents of the preferred implementations of other embodiments may be used as supplements to this embodiment unless conflicts or contradictions are caused.

[0067] A speed change device, preferably, such as figure 1As shown, the box body 1 is provided with at least two openings, one opening is located at one axial end of the worm 1 , and is used for connecting devices such as servo drives to the worm 1 . The worm wheel 2 is also provided with an opening at one axial end thereof, and the opening is used for connecting with a shaft coupling. Preferably, the axes are out of plane means that the worm axis 3a and the worm axis 2a are out-of-plane straight lines, the worm axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com