Design method for steel and concrete combined continuous beam hogging moment area

A technology of negative bending moment area and design method, applied in bridge construction, bridges, bridge materials, etc., can solve the problems of cumbersome trial calculation and lack of generality, and achieve the effect of clear concept, strong practicability and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

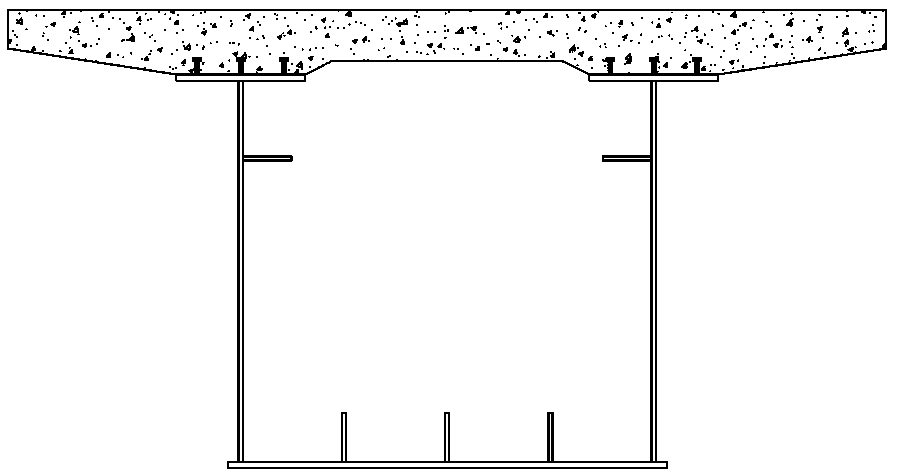

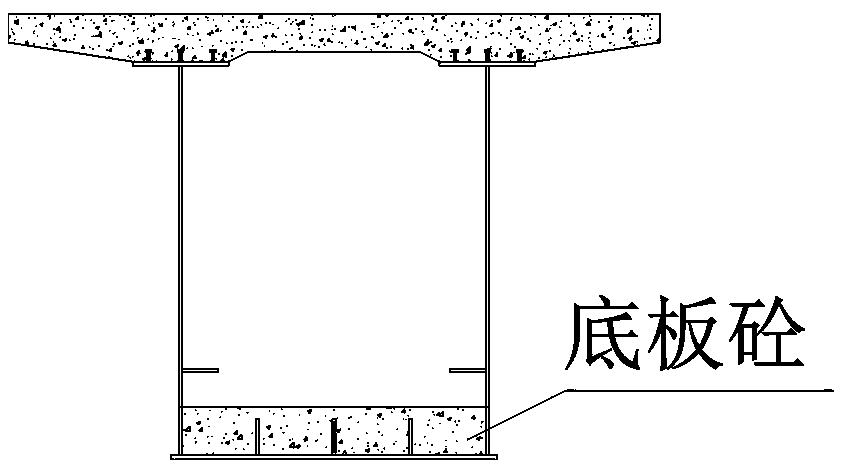

[0032] The design method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments. The design method of the invention is applicable to multi-span steel-concrete composite continuous beams and steel-concrete composite continuous beams with different spans.

[0033] One, in conjunction with accompanying drawing, the principle of the design method of the present invention is deduced and illustrated.

[0034] For highway bridges, the dead load accounts for more than 70% of the total load, so the bending moment of the steel-concrete composite continuous beam is basically determined by the dead load evenly distributed along the bridge span.

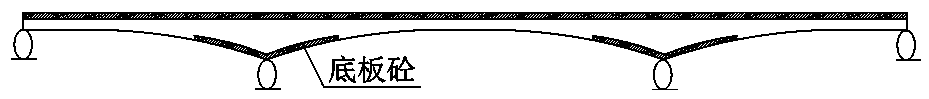

[0035] For a 2×L two-span steel-concrete composite continuous girder bridge, there is a uniformly distributed constant load q acting on the bridge, such as Figure 2.1 , the mid-span general se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com