Application of MXene as free radical initiator

An initiator, free radical technology, applied in the field of MXene and free radical polymerization, can solve the problems of long processing time and low efficiency, and achieve the effect of excellent photothermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Preparation of Ti by Ultrasonic Assisted Simultaneous Etching and Stripping Process 3 C 2 、Ti 2 C. Nb 2 C two-dimensional nanomaterials

[0042] Ti 3 C 2 Preparation of:

[0043] 0.125g Ti 3 AlC 2 Uniformly dispersed in 0.2g LiF / 2.5mL HCl (9M) solution, after 300W ultrasonic reaction for 6h, washed repeatedly with deionized water until the pH was about 5-6; then, centrifuged at 12000rpm for 10min to take the supernatant to obtain Ti 3 C 2 Nanosheets.

[0044] Ti 2 Preparation of C:

[0045] 0.09g Ti 2AlC is uniformly dispersed in 0.13g LiF / 2.5mL HCl (3M) solution, and after 300W ultrasonic reaction for 6h, it is washed repeatedly with deionized water until the pH is about 5-6; then it is centrifuged at 12000rpm for 10min to take the supernatant to obtain Ti 2 C nanosheets.

[0046] Nb 2 Preparation of C:

[0047] 0.144g Nb 2 AlC was evenly dispersed in 0.23g LiF / 3mL HCl (9M) solution, and after 300W ultrasonic reaction for 6h, it was repeated...

Embodiment 2

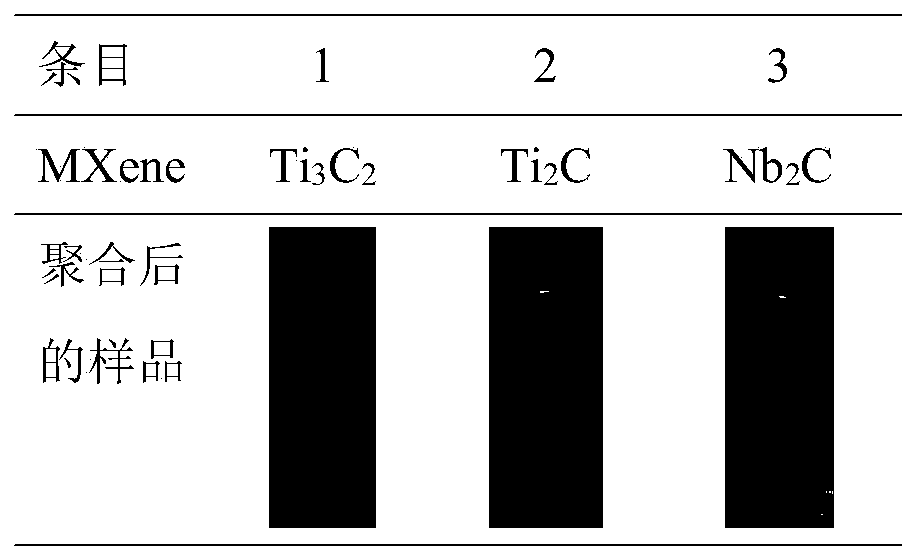

[0048] Embodiment 2. Different MXene materials (prepared in Example 1) initiate acrylamide polymerization

[0049] Take 80mg of acrylamide monomer and dissolve it in 1mL MXene (1.6wt%) nanosheets, and pass N under ice-cooling 2 After deoxygenation for 2 minutes, polymer hydrogel can be formed after reacting in the dark at 4°C for 10 minutes. The gel images obtained by polymerization of different MXenes are shown in figure 1 As shown, the gel sample does not flow after being inverted, indicating that different MXene materials can initiate monomer polymerization and further obtain gel.

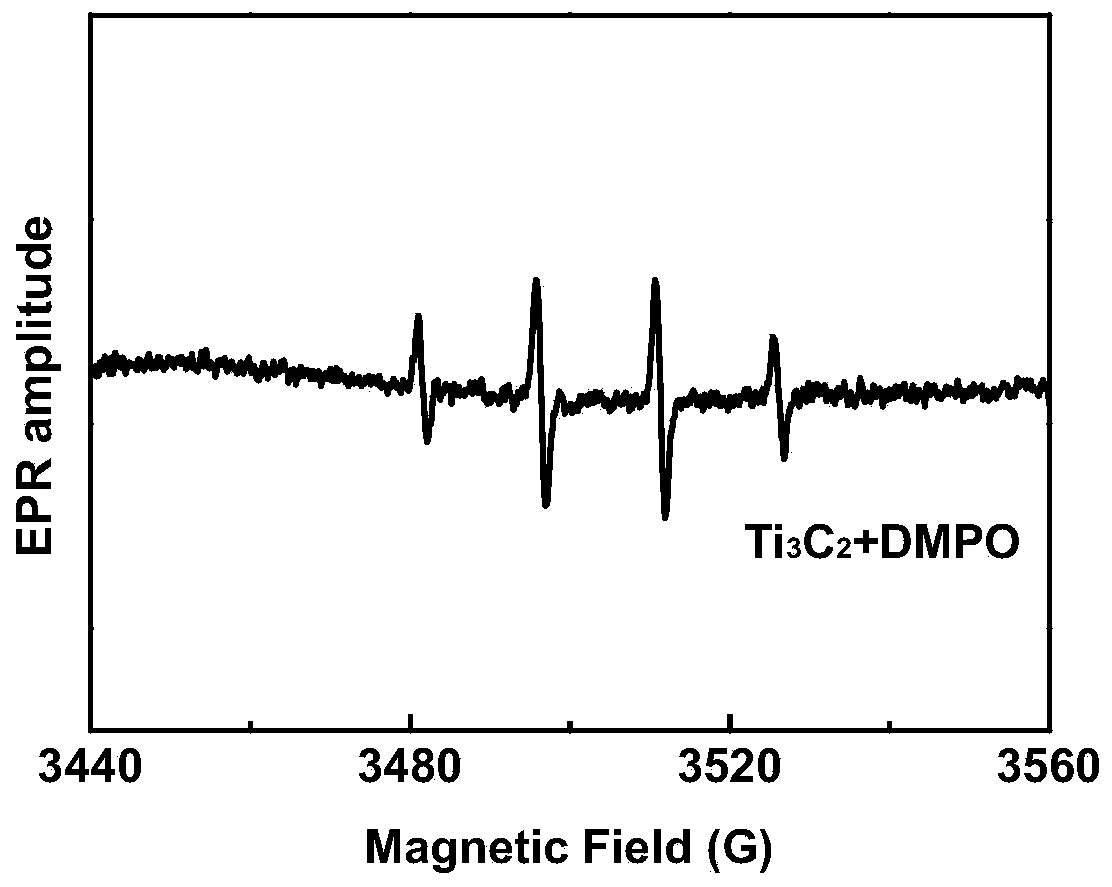

[0050] The MXene material of the present invention proves that the MXene system produces hydroxyl radicals by electron paramagnetic resonance spectrum (EPR), which can initiate monomer polymerization, as follows:

[0051] Dissolve 5 mg of 5,5-dimethyl-1-pyrroline oxide (DMPO) in 200 μL Ti 3 C 2 in, through Ti 3 C 2 Electron Paramagnetic Resonance Spectroscopy Bruker A300 spectrometer for f...

Embodiment 3

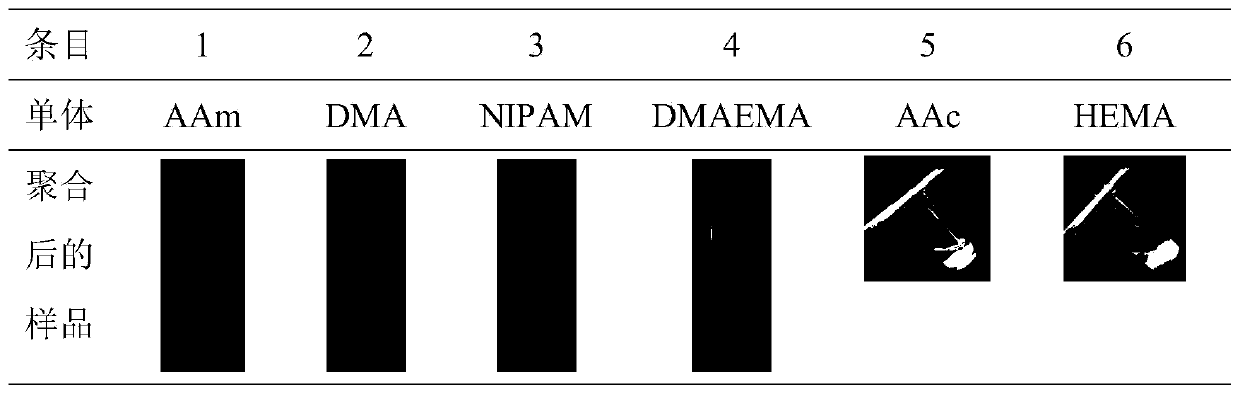

[0052] Example 3.Ti 3 C 2 Nanosheet (prepared in Example 1) initiates polymerization of different monomers

[0053] Take 80mg of N-isopropylacrylamide (NIPAM), N,N-dimethylacrylamide (DMA), acrylamide (AAm), dimethylaminoethyl methacrylate (DMAEMA), acrylic acid (AAc) and Hydroxyethyl methacrylate (HEMA) monomer was dissolved in 1 mL Ti 3 C 2 (1.6wt%) in the nanosheets, the N 2 After deoxygenation for 2 minutes, polymer hydrogels can be formed after 10 minutes of polymerization in the dark at 4°C. The polymer diagrams of different monomers are shown in image 3 As shown, Ti 3 C 2 Nanosheets can initiate polymerization of different monomers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com