New method for production of food-grade anhydrous glucose

An anhydrous glucose, food-grade technology, applied in the production of food-grade anhydrous glucose and the field of anhydrous glucose, can solve the problems of long process, unstable product quality, easy agglomeration, etc., to achieve short process, social benefits and environmental protection. Benefit, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

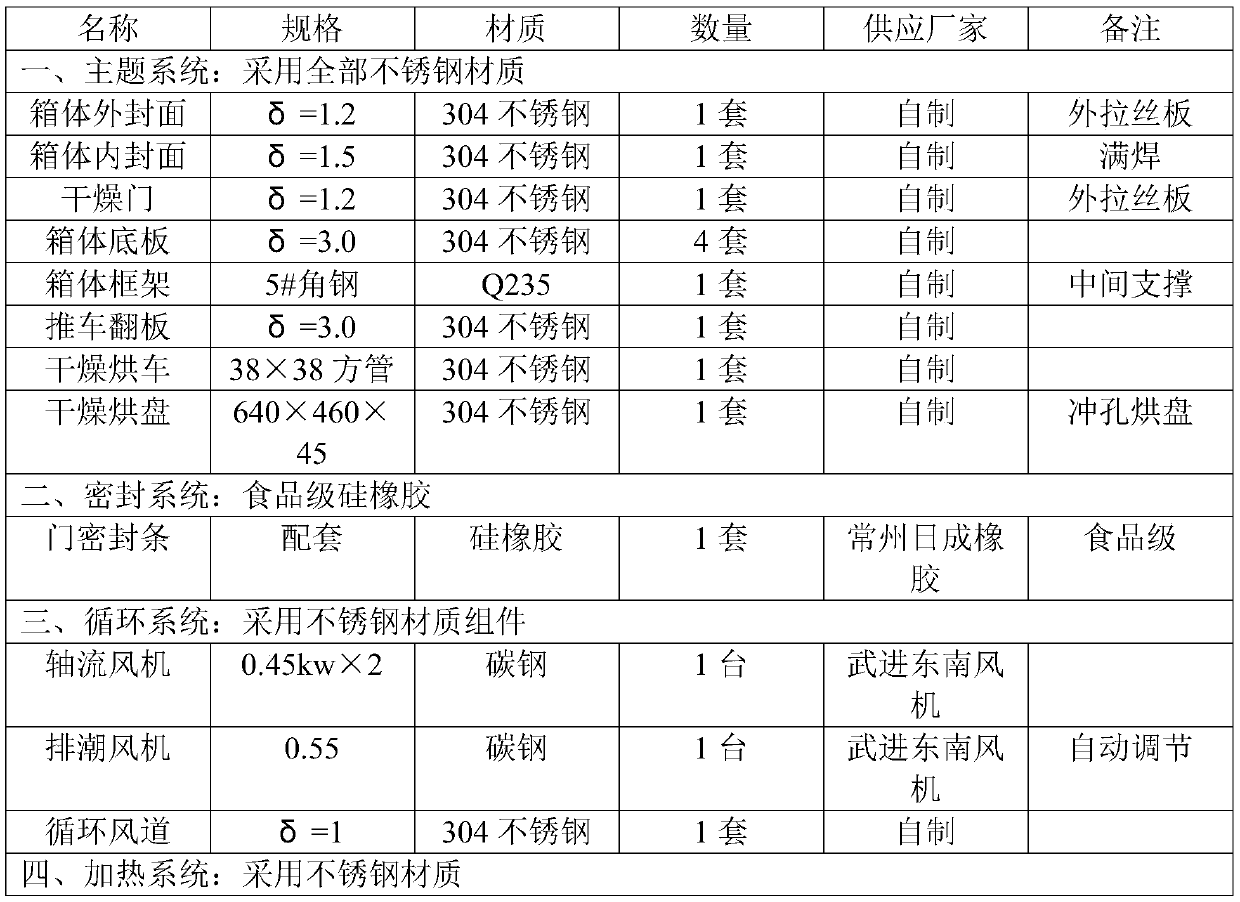

[0041] (1) Quantitatively pack the finished glucose monohydrate product into the baking tray of CT-C-II series hot air circulation oven according to 3kg / pan;

[0042] (2) Place the baking pan on the drying car;

[0043] (3) After the drying car is full, push it into the CT-C-II series hot air circulation oven;

[0044] (4) Start the CT-C-II series hot air circulation oven, adopt the electric heating method, set the drying temperature at 65°C, turn on the CT-C-II series hot air circulation oven fan, after 30 minutes the temperature reaches 65°C, and start automatic constant temperature circulation heating , Turn on the dehumidification fan to dehumidify, set it to automatically dehumidify for 2 minutes every 10 minutes, heat it at a constant temperature for 10 hours, take a sample to detect that the water content is 1.6%, stop heating, and after cooling, push the oven out;

[0045] (5) The qualified products in the baking tray are conveyed to the vibrating screen through the a...

Embodiment 2

[0047] (1) Quantitatively pack the finished glucose monohydrate product into the baking tray of CT-C-II series hot air circulation oven according to 3kg / pan;

[0048] (2) Place the baking pan on the drying car;

[0049] (3) After the drying car is full, push it into the CT-C-II series hot air circulation oven;

[0050] (4) Start the CT-C-II series hot air circulation oven, adopt the electric heating method, set the drying temperature at 60°C, turn on the CT-C-II series hot air circulation oven fan, after 25 minutes the temperature reaches 60°C, and start automatic constant temperature circulation heating , turn on the dehumidification fan to dehumidify, set it to automatically dehumidify for 2 minutes every 10 minutes, and heat it in a constant temperature cycle for 15 hours. Sampling and detection of moisture is 1.4%, stop heating, and after cooling, push the oven out;

[0051] (5) The qualified products in the baking tray are conveyed to the vibrating screen through the air d...

Embodiment 3

[0053] (1) Quantitatively pack the finished glucose monohydrate product into the baking tray of CT-C-II series hot air circulation oven according to 3kg / pan;

[0054] (2) Place the baking pan on the drying car;

[0055] (3) After the drying car is full, push it into the CT-C-II series hot air circulation oven;

[0056] (4) Start the CT-C-II series hot air circulation oven, adopt the electric heating method, set the drying temperature at 61°C, turn on the CT-C-II series hot air circulation oven fan, after 26 minutes the temperature reaches 61°C, and start automatic constant temperature circulation heating , Turn on the dehumidification fan to dehumidify, set it to automatically dehumidify for 2 minutes every 10 minutes, heat at a constant temperature for 14 hours, take a sample to detect that the water is 1.5%, stop heating, and after cooling, push out the oven;

[0057] (5) The qualified products in the baking tray are conveyed to the vibrating screen through the air delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com