Doped modified Gd2Zr2O7 ceramic material and preparation method thereof

A technology of gd2zr2o7 and ceramic materials, applied in the field of thermal barrier coating ceramic materials, can solve problems such as improvement of unfavorable material thermal physical properties, and achieve the effect of convenient thermal physical properties and convenient research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides the doped modified Gd described in the above scheme 2 Zr 2 o 7 A method for preparing a ceramic material, comprising the steps of:

[0050] (1) Gd 2 o 3 , ZrO 2 and Nb 2 o 5 Carry out mixed ball milling to obtain a mixture;

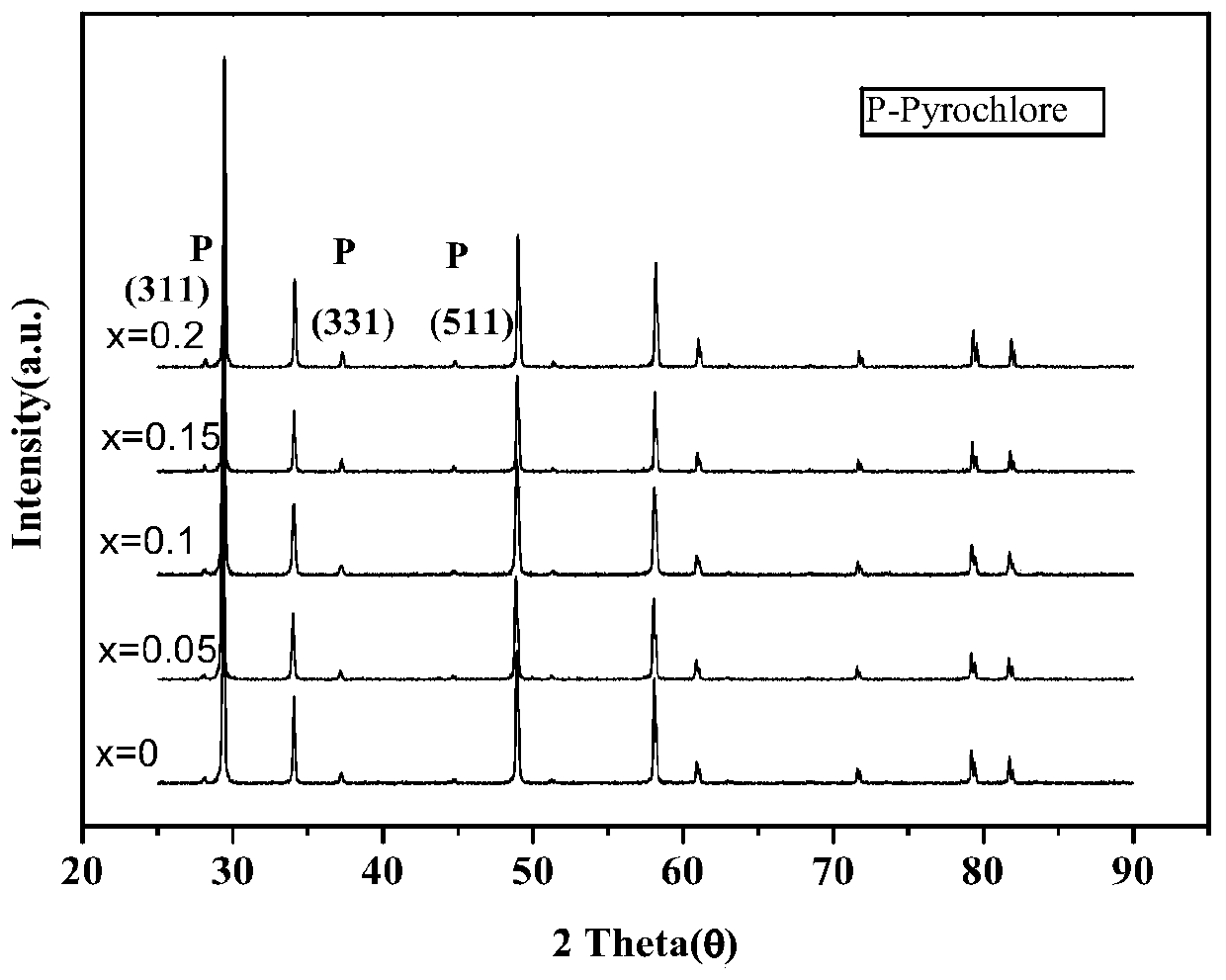

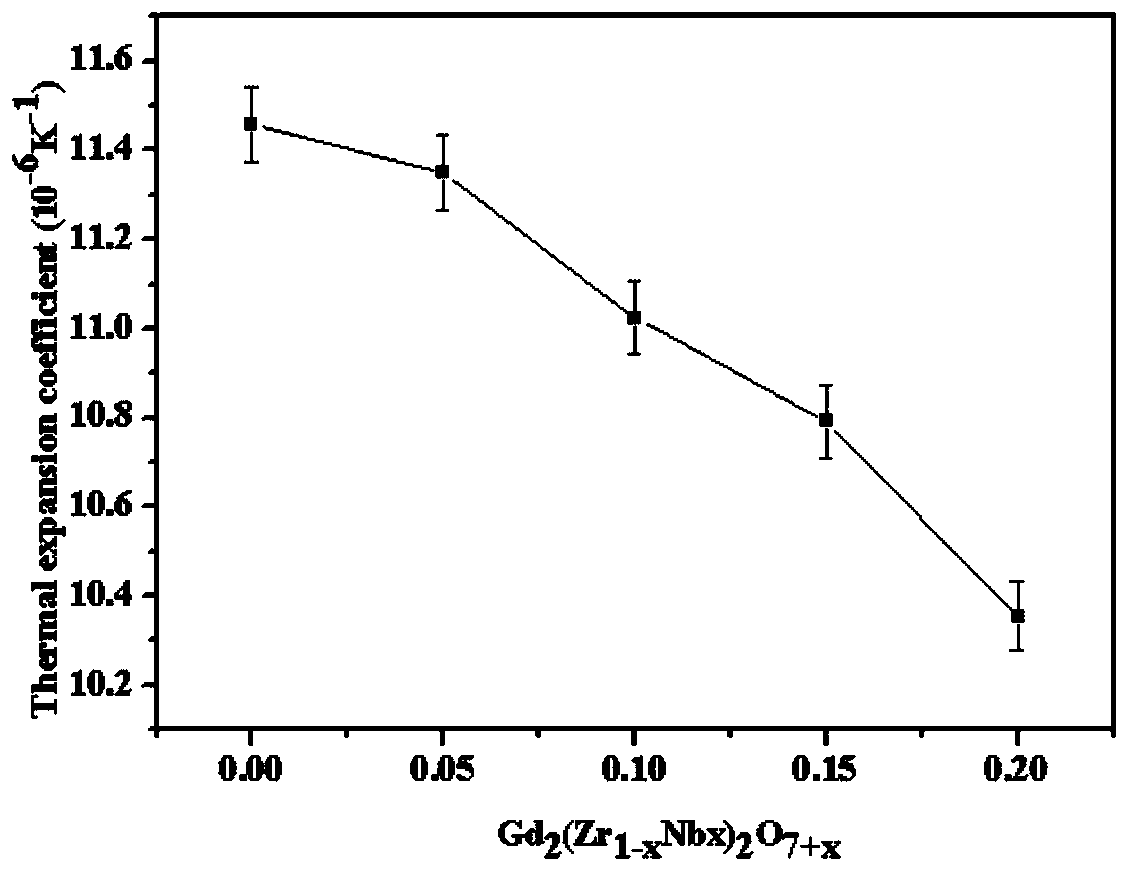

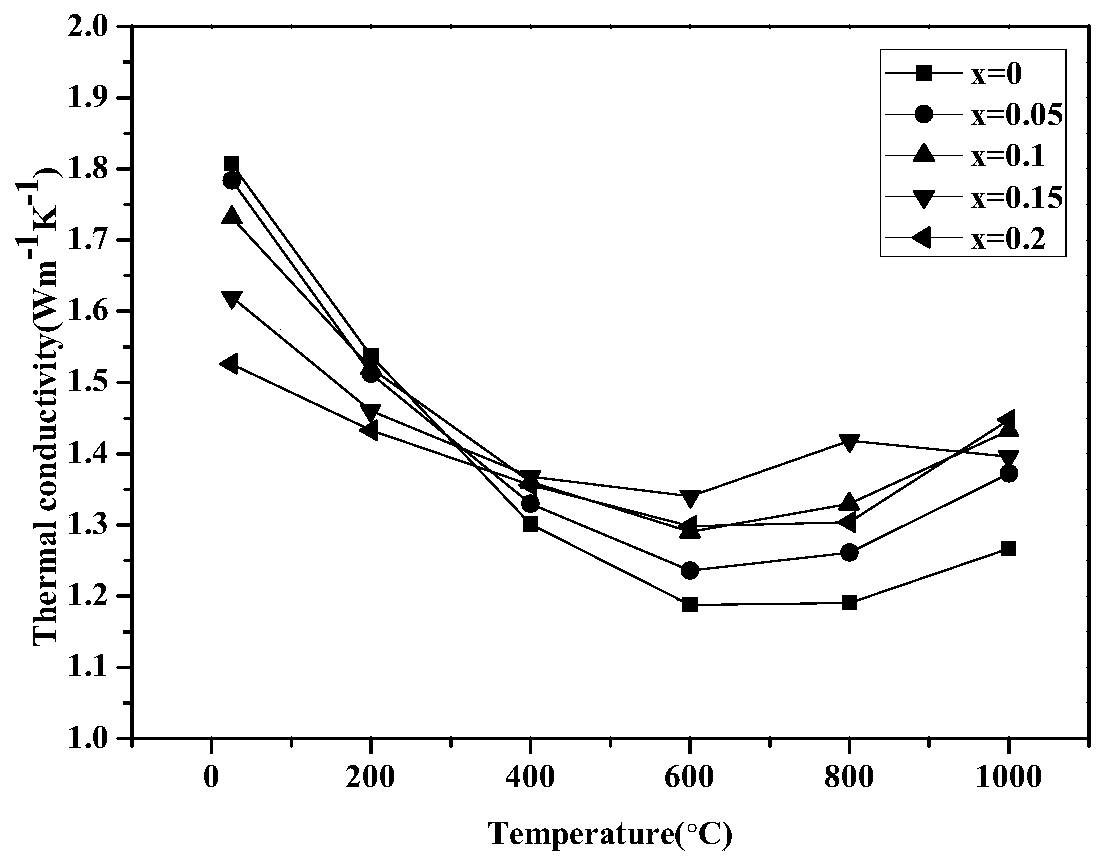

[0051] The Gd 2 o 3 , ZrO 2 and Nb 2 o 5 The dosage is calculated according to the chemical composition shown in formula 1; Gd 2 (Zr 1-x Nb x ) 2 o 7+x Formula 1; 0<x≤0.3 in said formula 1;

[0052] (2) Carrying out the first sintering of the mixed material to obtain a sintered material;

[0053] (3) performing secondary ball milling on the sintered material to obtain sintered powder;

[0054] (4) Compressing the sintered powder to obtain a biscuit;

[0055] (5) Carrying out the second sintering of the green compact to obtain doped modified Gd 2 Zr 2 o 7 Ceramic material.

[0056] In the present invention, unless otherwise specified, the raw materials used are commercially available products we...

Embodiment 1

[0083] (1) Gd 2 o 3 , ZrO 2 and Nb 2 o 5 Put different zirconia crucibles into a resistance furnace, and bake at 800°C for 2 hours to remove the moisture absorbed by the raw materials;

[0084] (2) Weigh 29.675g Gd according to the stoichiometric ratio 2 o 3 , 18.15g ZrO 2 and 2.175gNb 2 o 5 , put it into a polyurethane ball mill tank with zirconia balls as the grinding body, add 100g of ethanol, and then put the polyurethane ball mill tank filled with materials on a planetary ball mill for ball milling for 24 hours, the ball mill speed is 480r / min, pour out the slurry after ball milling The material was placed in a drying oven and dried at 70°C for 12 hours to obtain a mixture;

[0085] (3) Put the mixture into a zirconia crucible and sinter in a high-temperature furnace at 1500° C. for 6 hours to obtain a sintered material.

[0086] (4) Put the sintered material into the polyurethane ball milling tank again for secondary ball milling, put it into an agate mortar an...

Embodiment 2

[0091] The difference with Example 1 is that weighing 29.58g Gd 2 o 3 , 16.085g ZrO 2 and 4.335g Nb 2 o 5 , the resulting doped modified Gd 2 Zr 2 o 7 The chemical composition of the ceramic material is: Gd 2 (Zr 0.8 Nb 0.2 ) 2 o 7.2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com