Water riser pipe transferring system

A riser and transfer technology, which is applied to the transportation of passenger cars, transportation and packaging, railway car body parts, etc., can solve the problems of reducing the working efficiency of riser transfer trolleys, large winch occupation area, and prone to tipping accidents, etc. , to avoid tipping accidents, save floor space, and reduce handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

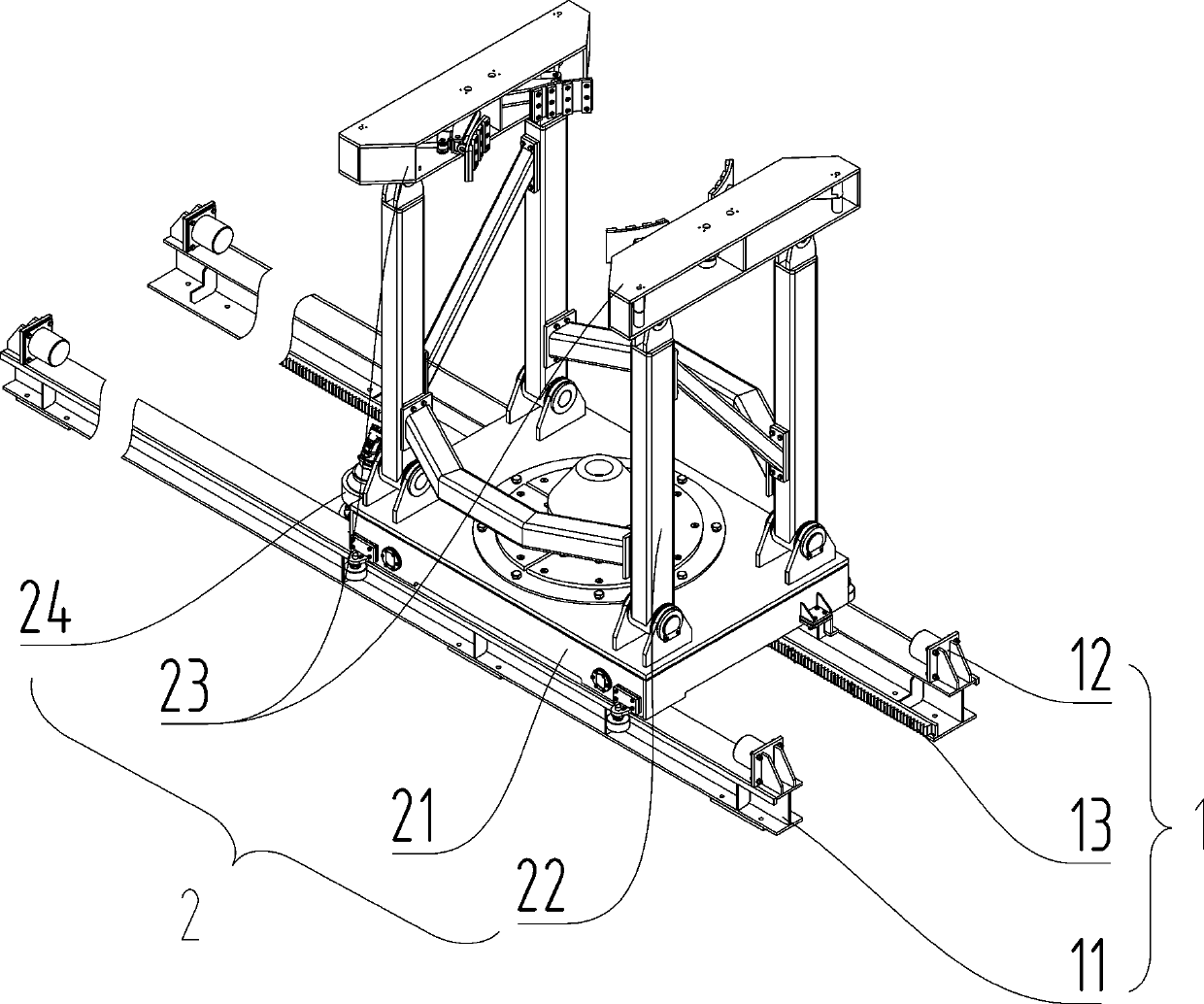

[0065] Such as figure 1 As shown in -2 and 5-10, the riser transfer system is composed of a rail assembly 1 and a transfer trolley 2. The rail assembly 1 consists of a rail 11 fixedly connected to the deck, and 4 buffers fixedly connected to the two rails 11. 12 and a rack 13, four buffers 12 are respectively fixed on the two ends of the two rails 11, the rack 13 is fixedly connected to the inner side of one rail 11, and the rack 13 is vertically fixedly connected, in other embodiments The middle rack 13 can be fixedly connected horizontally. In other embodiments, the rack 13 can be fixedly connected to the outside of a track; The structure 22 is composed of a reducer assembly 24 fixedly connected to the base 21 and a centralizer 23 movably connected to the frame structure 22. The number of centralizers is 2, and the two centralizers 23 are arranged in parallel. The centralizer 23 is perpendicular to the track assembly 1 .

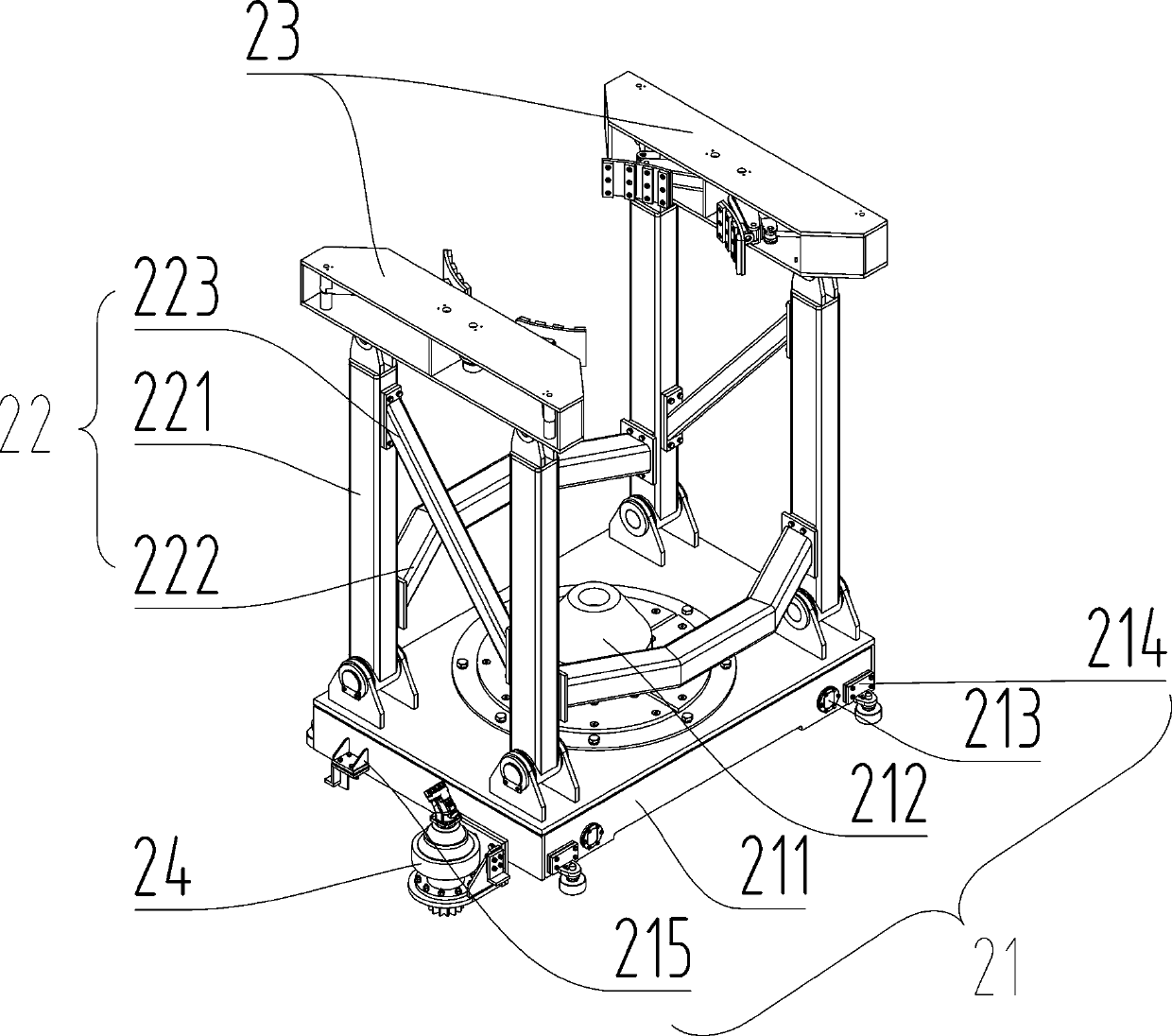

[0066] The base 21 is composed of a chassis 211, ...

Embodiment 2

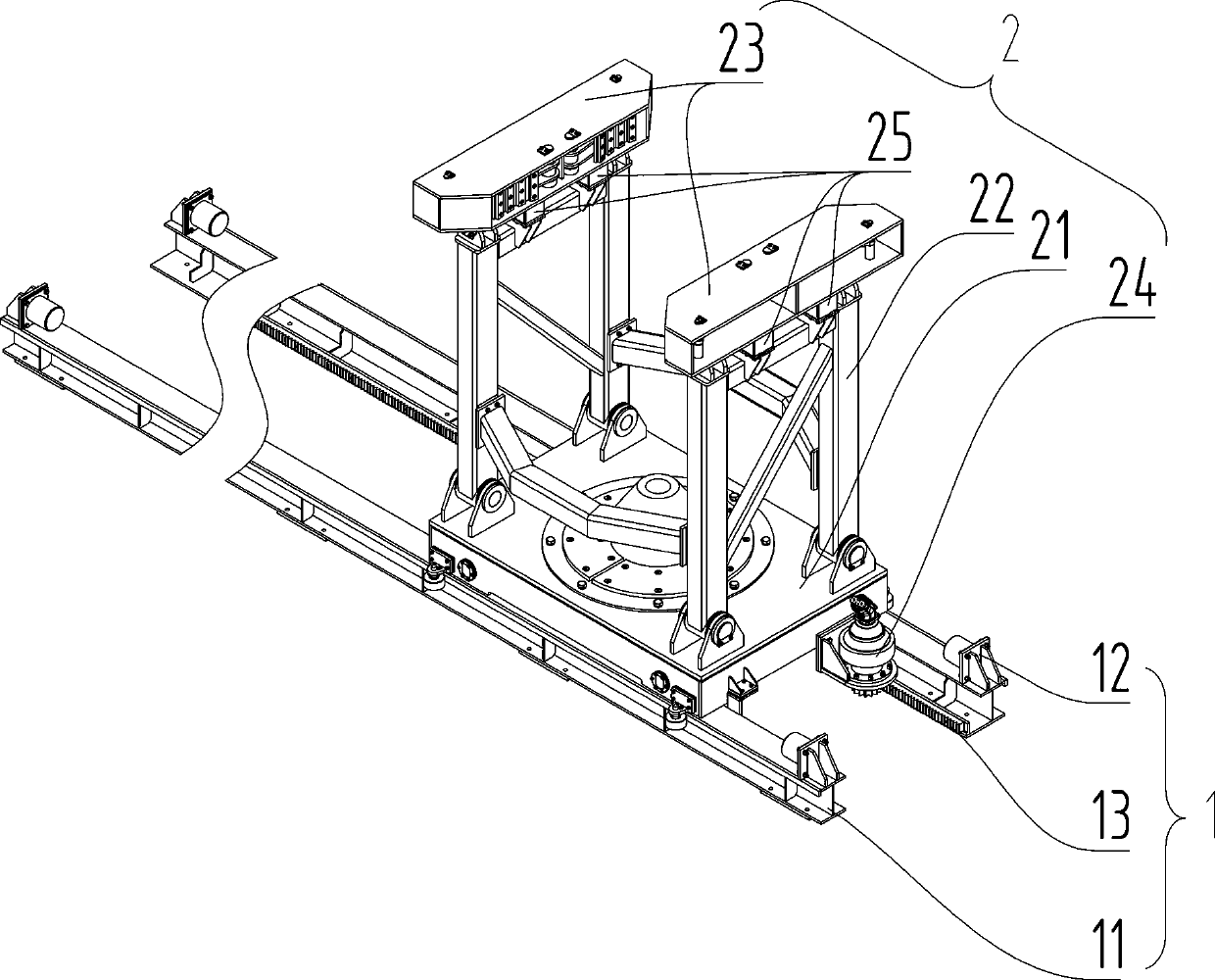

[0071] Such as image 3 As shown in -4 and 5-10, the riser transfer system is composed of a rail assembly 1 and a transfer trolley 2. The rail assembly 1 consists of a rail 11 fixedly connected to the deck, and 4 buffers fixedly connected to the two rails 11. 12 and a rack 13, four buffers 12 are respectively fixed on the two ends of the two rails 11, the rack 13 is fixedly connected to the inner side of one rail 11, and the rack 13 is vertically fixedly connected, in other embodiments The middle rack 13 can be fixedly connected horizontally. In other embodiments, the rack 13 can be fixedly connected to the outside of a track; The structure 22 consists of a reducer assembly 24 fixedly connected to the base 21, a rubber block 25 fixedly connected to the frame structure 22 and a centralizer 23 movably connected to the frame structure 22. In this embodiment, the number of rubber blocks 25 is four , the number of centralizers is 2, two centralizers 23 are arranged in parallel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com