Side pushing grid manufacturing method

A manufacturing method and grid technology, applied to ship components, ships, transportation, packaging, etc., can solve the problems of difficulty in making side push grids, and the inability to directly determine the actual size of the ellipse, so as to achieve convenience in the manufacturing process and avoid shape parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

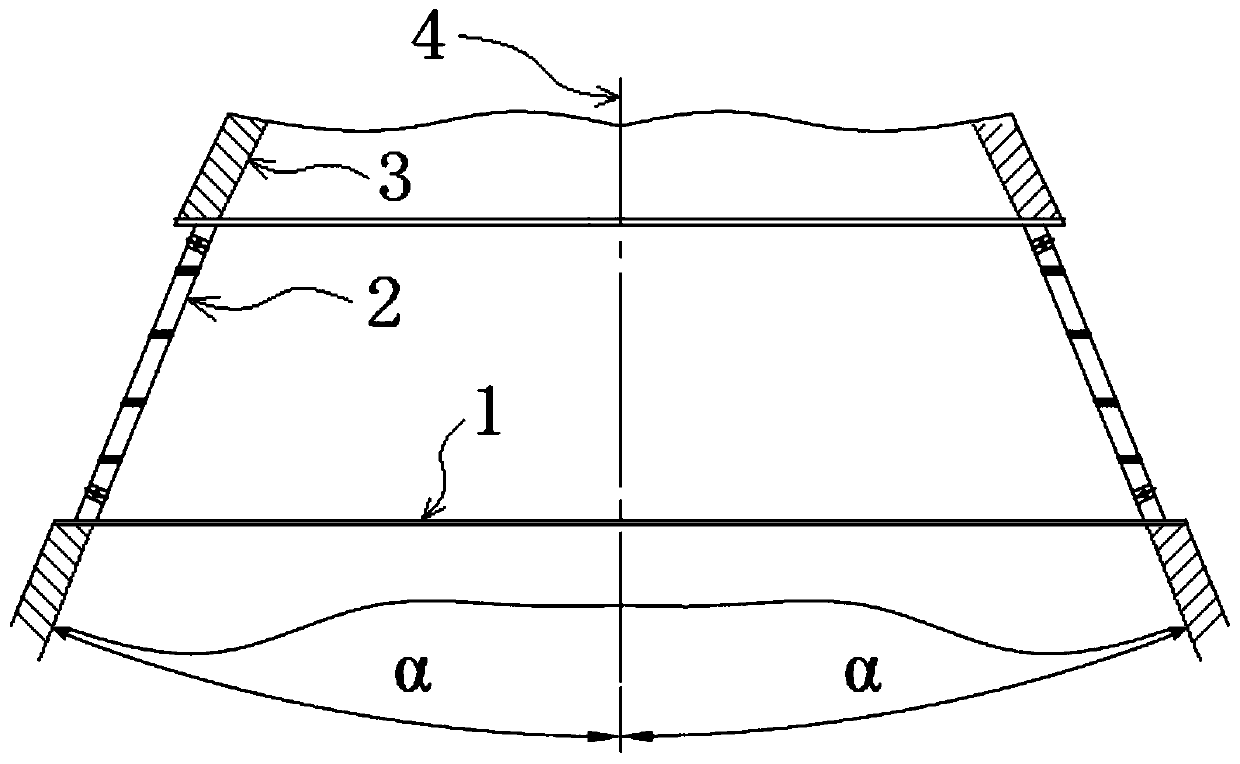

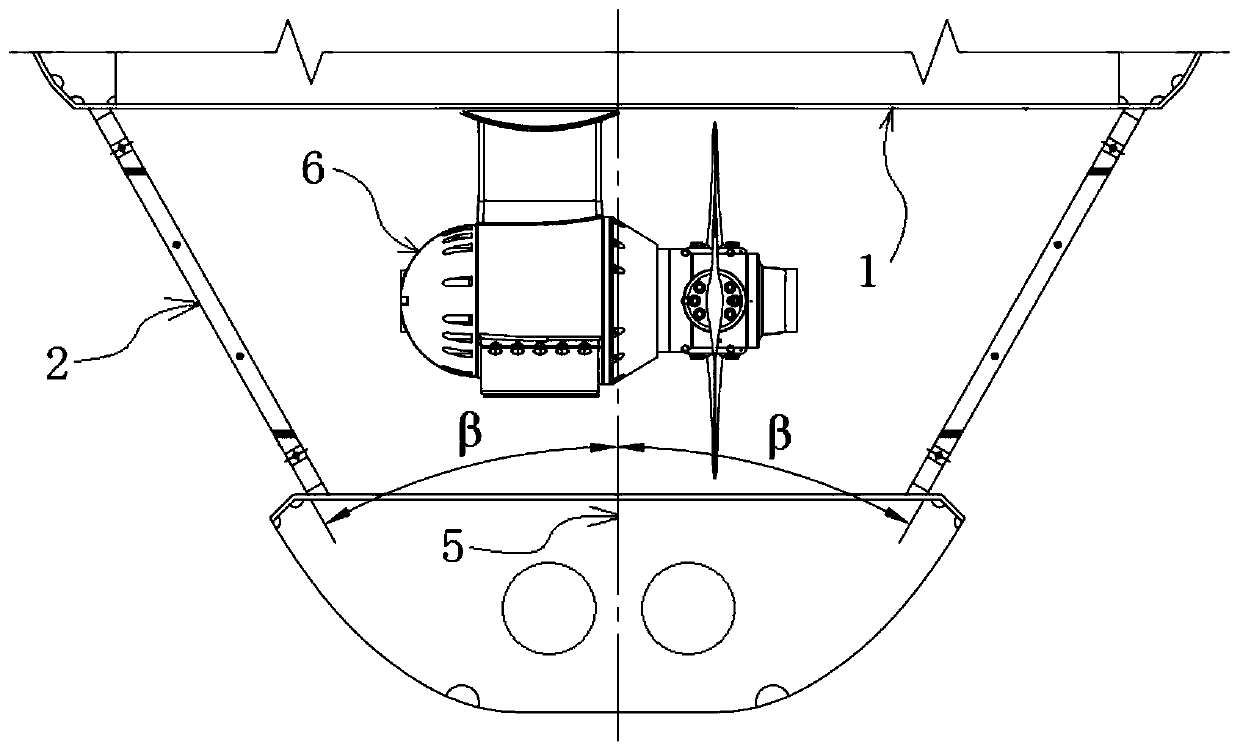

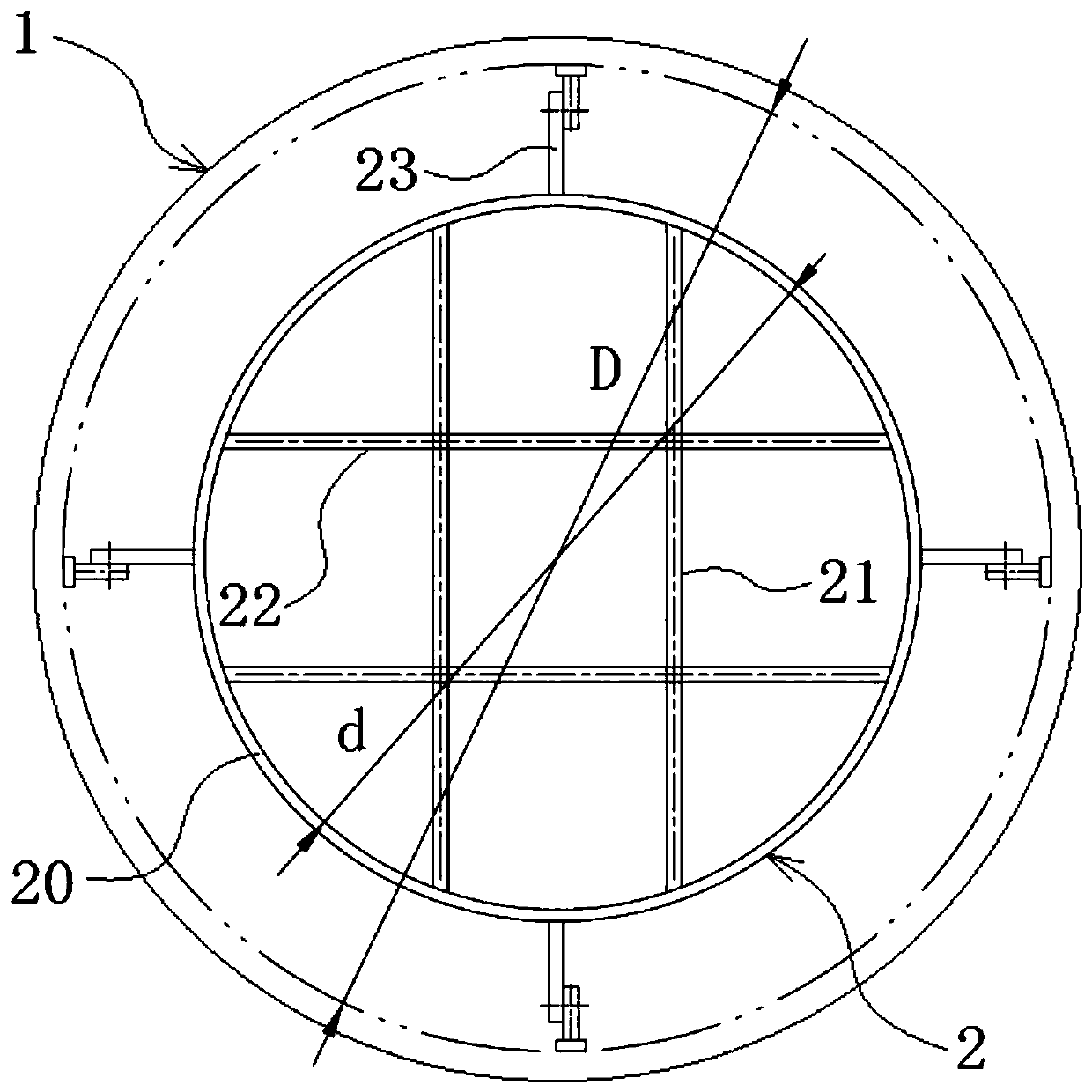

[0033] Specific embodiment 1 of the manufacturing method of the lateral push grille of the present invention. The manufacturing method of the lateral push grille is to determine the specific parameters of the lateral push grille 2 according to the design parameters of the hull, and then make a product that matches the shape of the hull Push the grille 2. At the beginning of the ship design, in order to ensure the stability and sailing ability of the ship, the hull is usually designed to be wide at the top and narrow at the front and rear ends. Therefore, the hull plate 3 is in the horizontal direction at the bow and stern. There is a certain angle of inclination in the vertical direction. Such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com