Aluminum-plastic composite bag printing machine and printing method of aluminum-plastic composite bag

A technology of aluminum-plastic composite and composite bags, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., to achieve the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

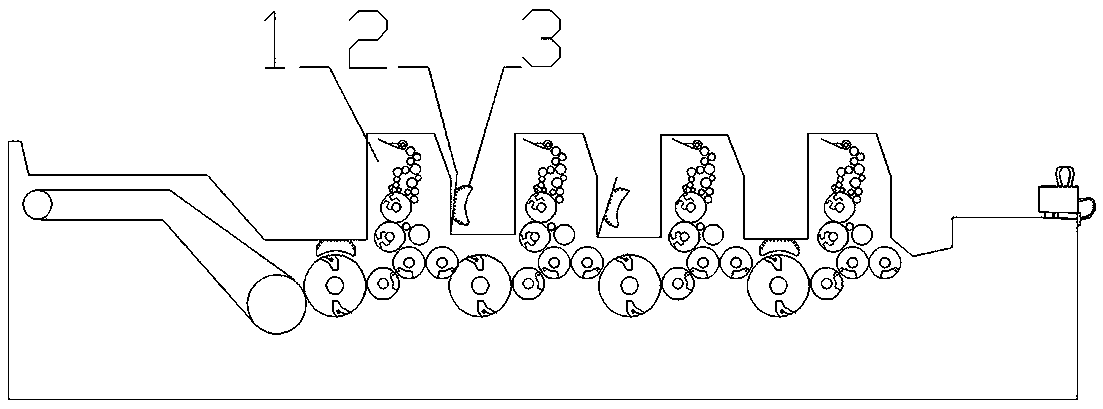

[0036] Such as Figure 1 to Figure 5 As shown, an aluminum-plastic composite bag printing machine includes a printing unit 1, a connecting plate 2 is arranged between the printing units, and a storage roller 14 for transferring printing paper is arranged under the connecting plate 2. The number of the printing units 1 is at least Two, each printing unit 1 is equipped with a UV curing device 3, and the UV curing device 3 is fixedly connected to the lower surface of the connecting plate 2;

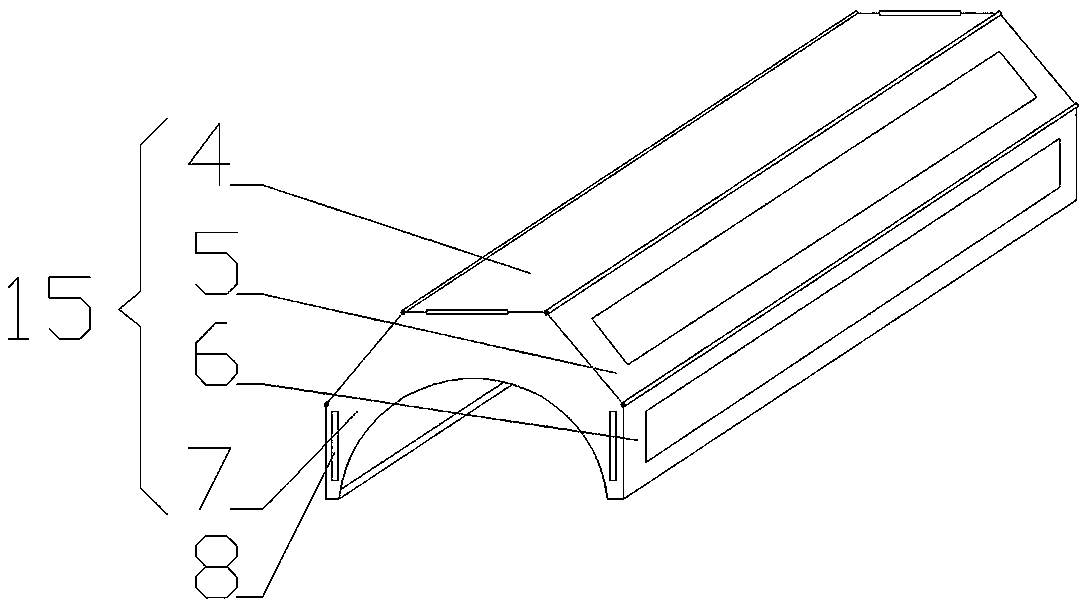

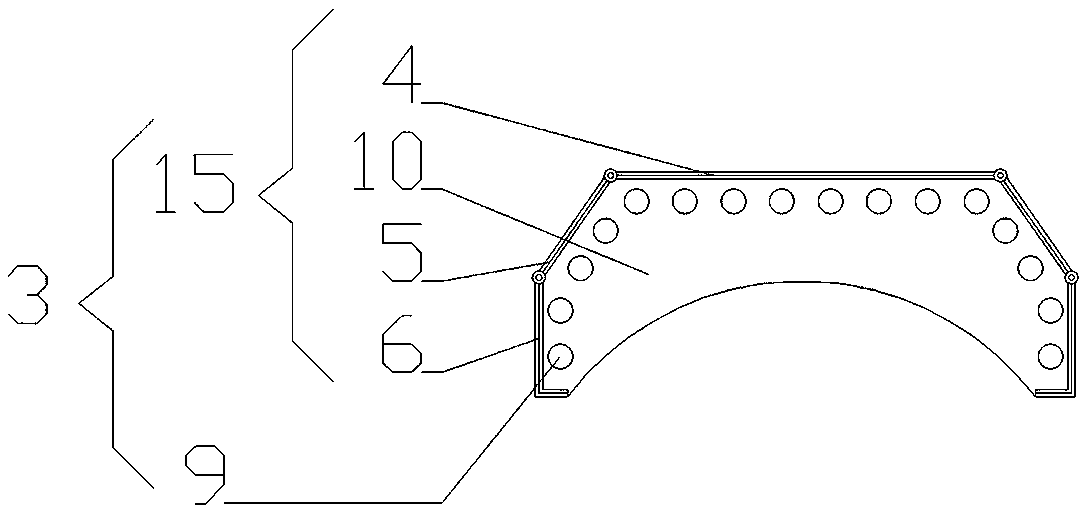

[0037] The UV curing device 3 includes a housing 15, a UV lamp 9 and a control switch. The housing 15 is provided with a plurality of UV lamps 9, the UV lamps 9 are cylindrical, and the plurality of UV lamps 9 Equidistantly installed inside the casing 15, the UV lamp tube 9 is connected to the control switch through a cable, and the control switch is fixed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com