Pipe fitting cleaning device and cleaning system thereof

A cleaning device and cleaning system technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as complicated operation, reduced work efficiency, and contamination of the outer surface of steel pipes, and achieve high cleaning efficiency and structure Simple, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

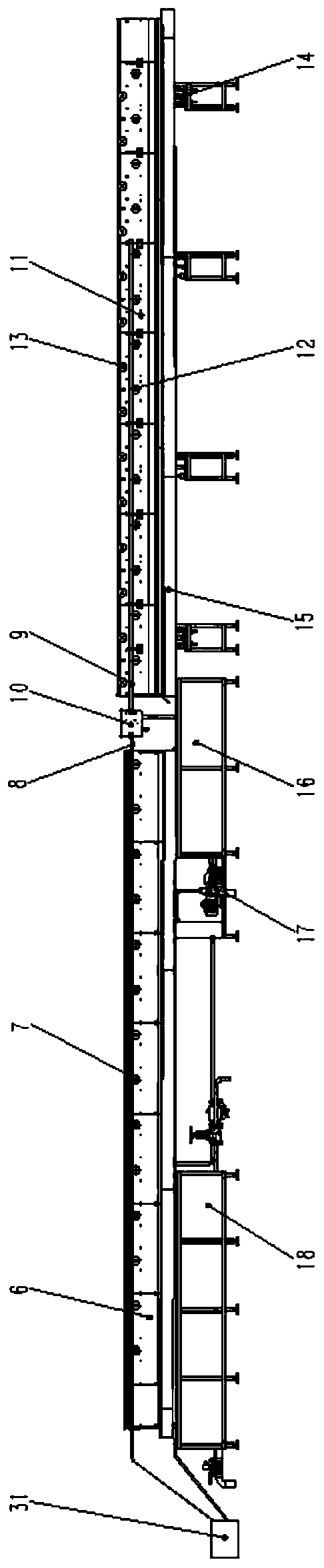

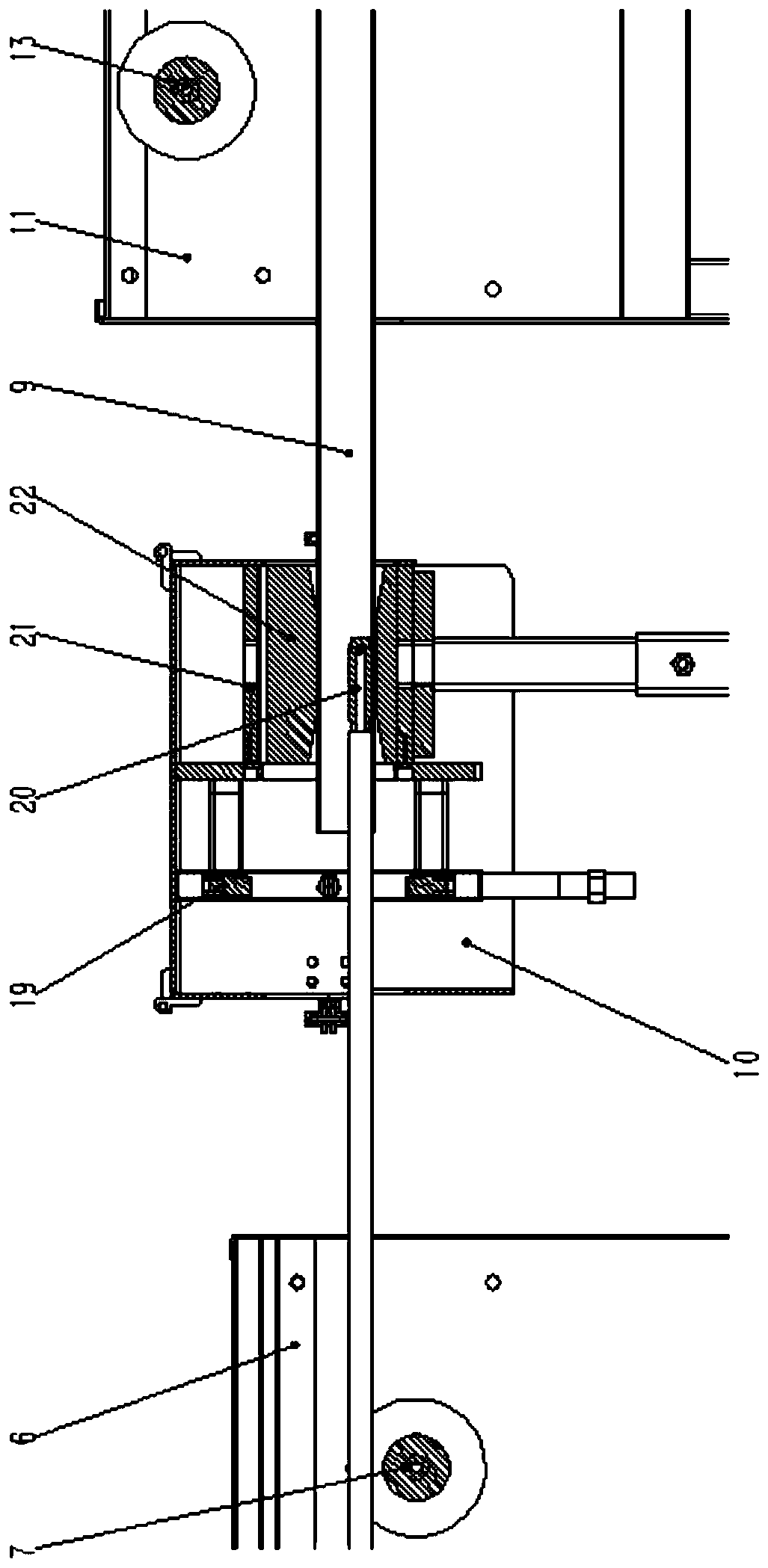

[0043] The pipe cleaning device of this embodiment, such as figure 1 Shown, comprise movable transmission box 11, fixed transmission box 6, the first cleaning box 10 and high-pressure cleaner 31, the first cleaning box 10 is arranged between movable transmission box 11 and fixed transmission box 6, and movable transmission box 11 inside is provided with There are a first transmission mechanism 12 and a third transmission mechanism 13, the third transmission mechanism 13 is located above the first transmission mechanism 12, the second transmission mechanism 7 is arranged inside the fixed transmission box 6, and the first cleaning mechanism 10 is provided in the first cleaning box 10. Assemblies, the movable transmission box 11, the fixed transmission box 6 and the first cleaning box 10 can prevent the cleaning solution from splashing or dripping to the surroundings.

[0044] The movable transmission box 11 moves up and down under the control of the control mechanism. The contro...

Embodiment 2

[0053] The pipe cleaning system of this embodiment, such as Figure 4 As shown, there are three sets of pipe fitting cleaning devices as described in Embodiment 1, which are cleaning line 1, rinsing line 2 and antirust line 3 respectively.

[0054] The cleaning solution on cleaning line 1 is a mixture of environmentally friendly cleaning agent and water in a certain proportion, the cleaning solution on rinsing line 2 is water, and the cleaning solution on antirust line 3 is a mixture of antirust agent and water in a certain proportion. Mixture. The use of three cleaning lines can clean the pipe fittings according to the needs to achieve the required cleaning effect.

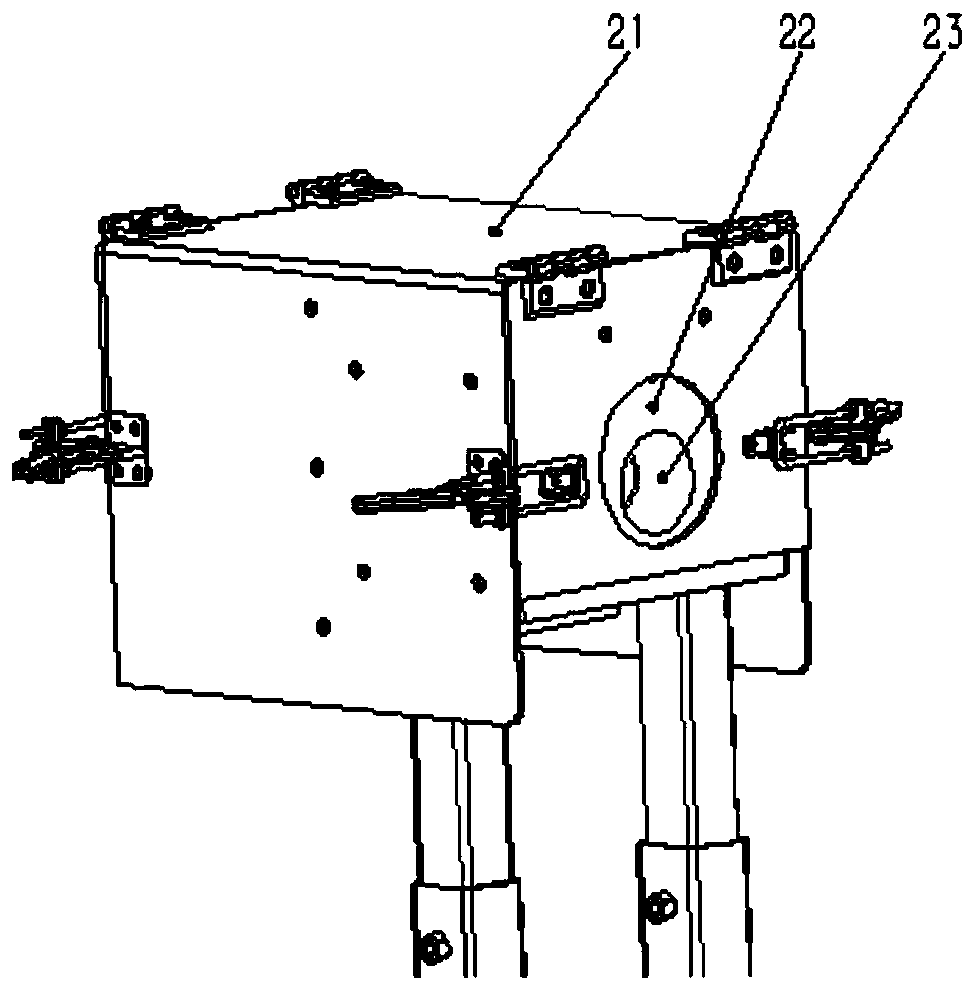

[0055] like Figure 5 , Image 6 As shown, the pipe fitting cleaning system includes a connecting mechanism for transferring the pipe fitting 9 from the cleaning line 1 to the adjacent rinsing line 2, and transferring the pipe fittings on the rinsing line 2 to the adjacent antirust line 3, the connecting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com