Multi-layered sheet material having at least one woven reinforcement fabric, transition element having such multi-layered sheet material, and vehicle, passenger boarding bridge, or passenger stairs having such transition element

A multi-layer sheet, fabric sheet technology, applied in vehicle parts, household components, railway car body parts, etc., can solve the problem of cumbersome sandwiching of foldable walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

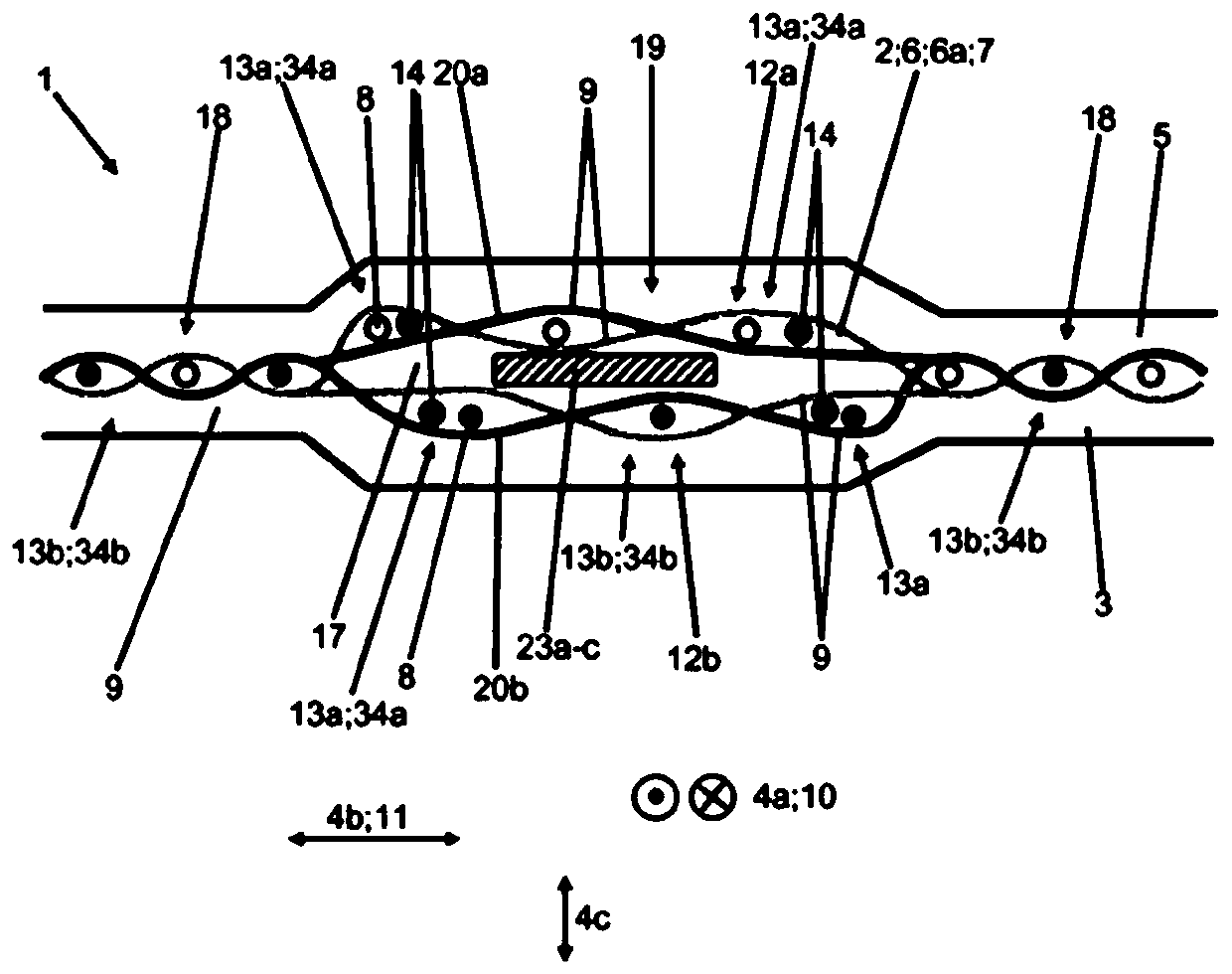

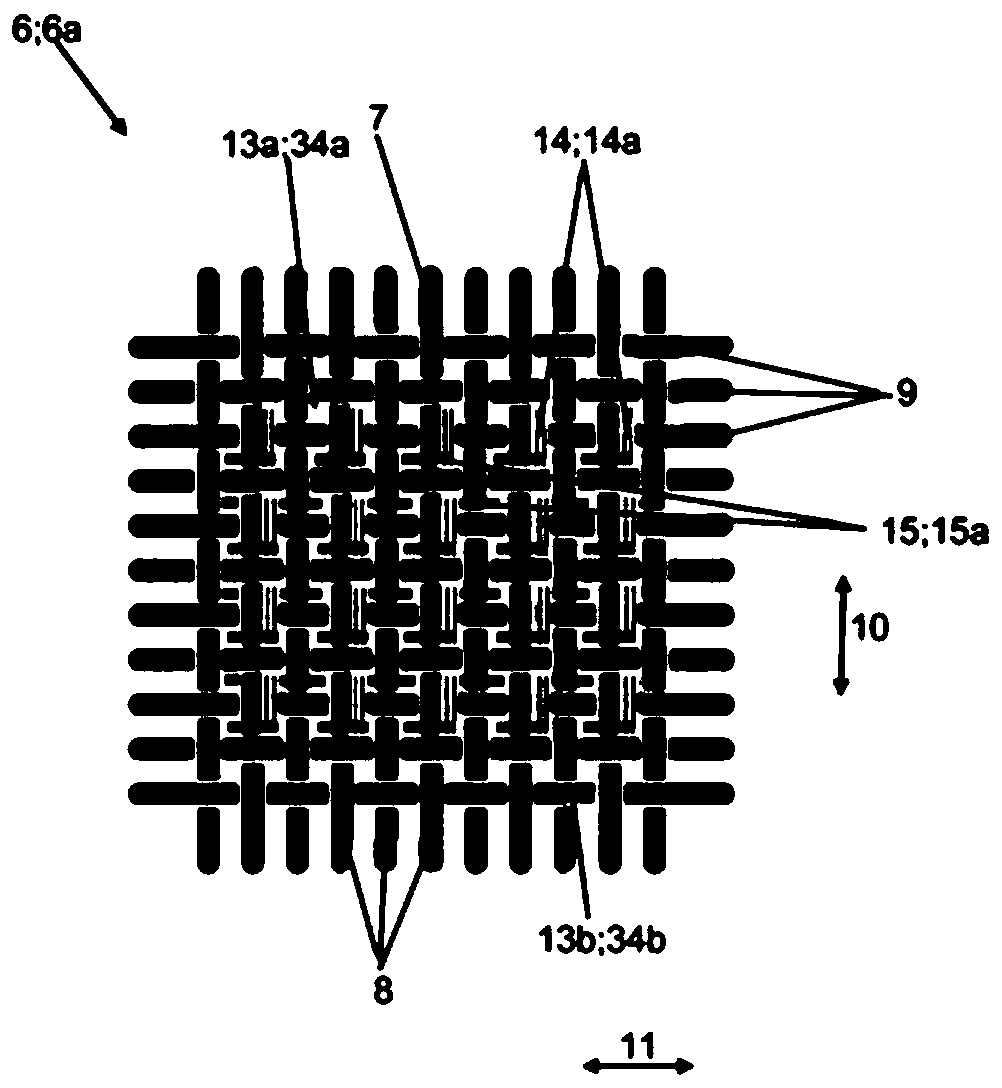

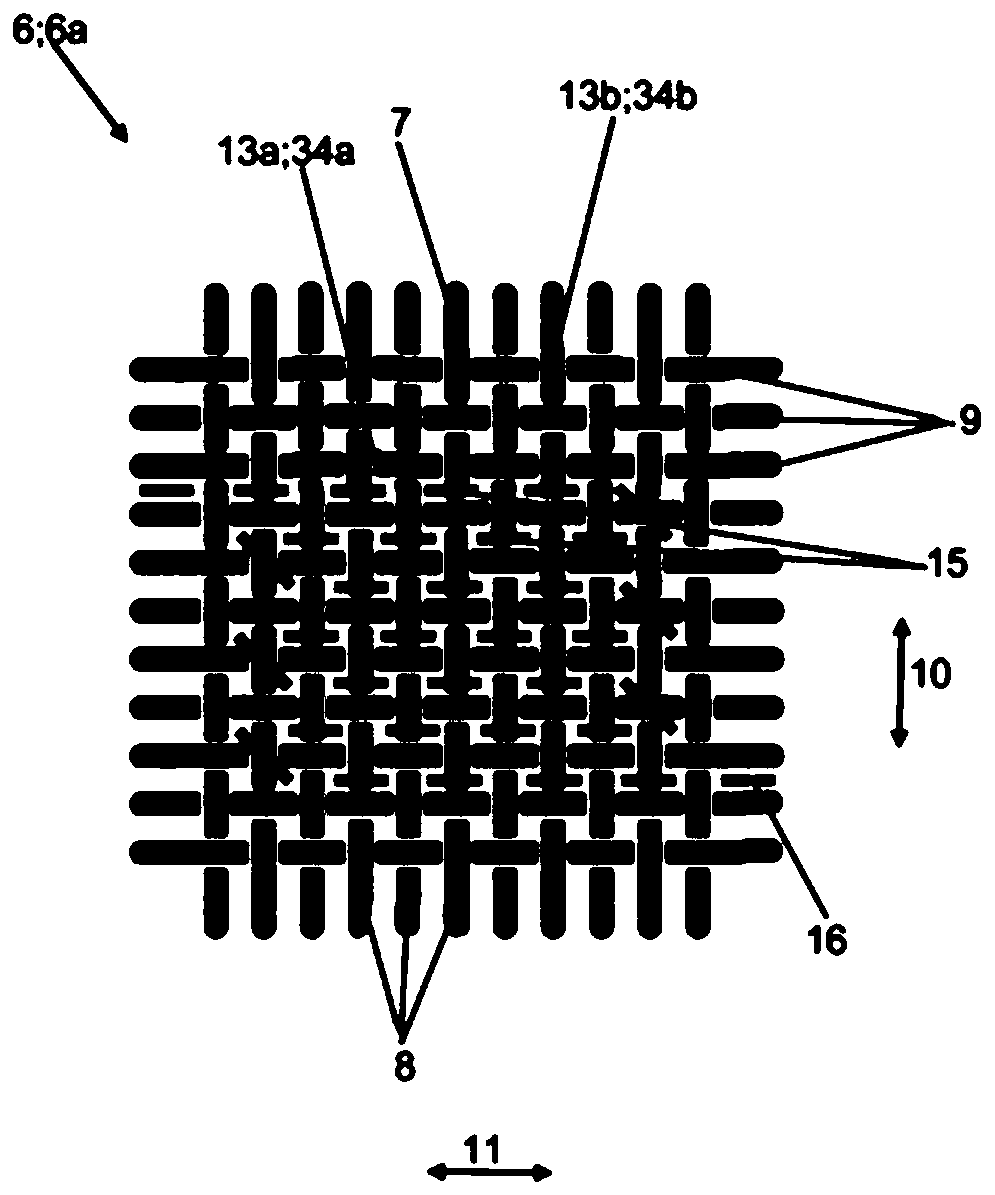

[0017] According to the multilayer flexible sheet 1 of the present invention ( figure 1 ) has a central flat reinforcing carrier layer or a central flat reinforcing carrier 2 which has an outer or outer polymer coating 3 on both sides. The polymer coating 3 respectively forms the outer side of the multilayer sheet 1 .

[0018] The multilayer sheet 1 also has a first spatial or areal direction 4a and a second spatial or areal direction 4b perpendicular thereto. In other words, the multilayer sheet 1 has a planar surface in the first and second direction 4a; extend. In addition, the sheet 1 has a thickness direction or height direction 4c which is perpendicular to the two face directions 4a;b. The flat reinforcing carrier 2 therefore also has a planar extension in the first and second areal directions 4a; 4b, or a height or thickness extension in the thickness direction 4c.

[0019] The polymer coating 3 has a polymer matrix 5 in which fillers, in particular flame-retardant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com