Superjunction device structure and method for fabricating same

A technology of superjunction device and column structure, applied in the field of superjunction device structure and its preparation, can solve problems such as uneven defects in the superjunction drift region, and achieve a technology suitable for large-scale production, optimized reverse recovery characteristics and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

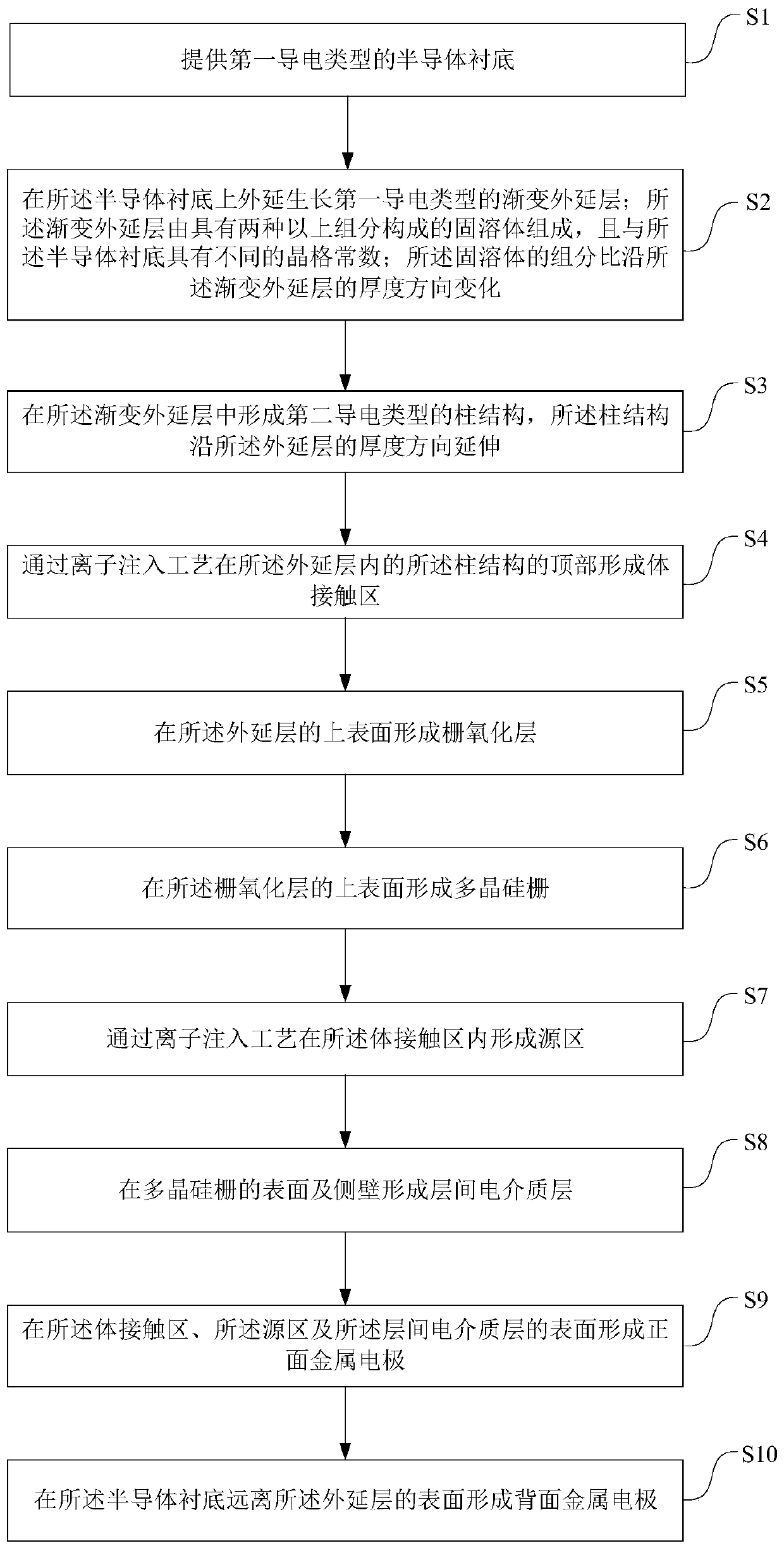

[0067] see Figure 1 to Figure 12 , the invention provides a method for preparing a superjunction device structure, comprising the following steps:

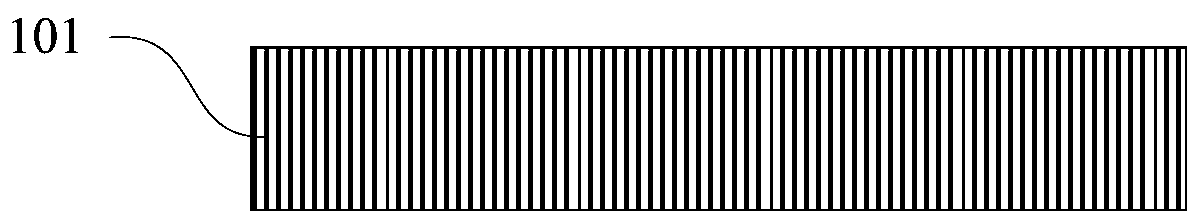

[0068] 1) providing a semiconductor substrate 101 of the first conductivity type;

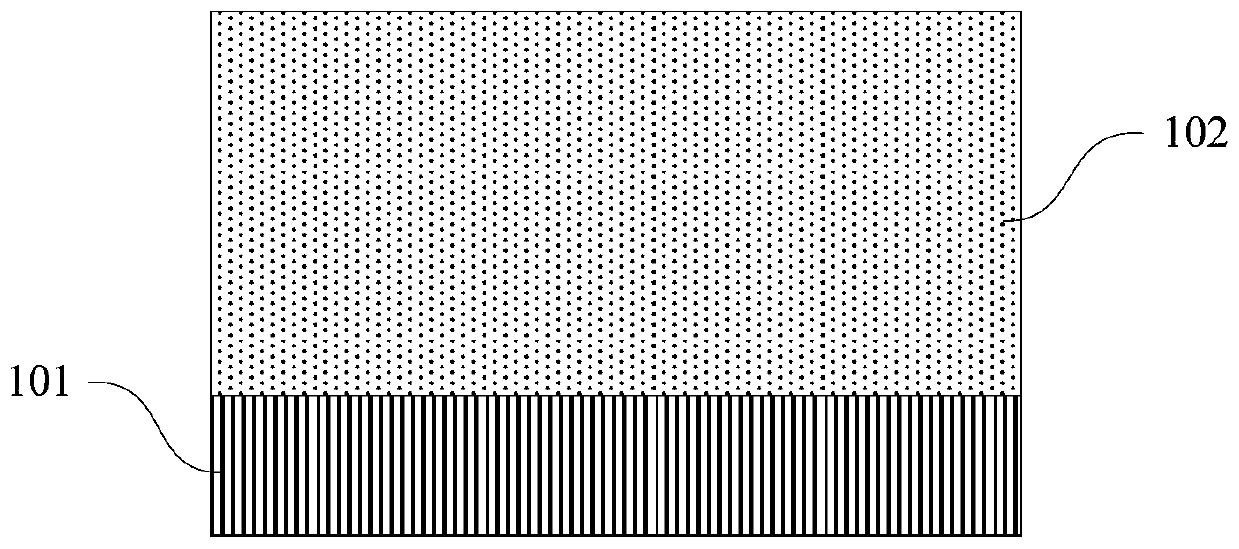

[0069] 2) Epitaxially growing a graded epitaxial layer 102 of the first conductivity type on the semiconductor substrate 101; the graded epitaxial layer 102 is composed of a solid solution composed of two or more components, and has a different The lattice constant; the composition ratio of the solid solution changes along the thickness direction of the graded epitaxial layer 102;

[0070] 3) Forming a column structure 103 of the second conductivity type in the graded epitaxial layer 102 , and the column structure 103 extends along the thickness direction of the graded epitaxial layer 102 .

[0071] In step 1), see figure 1 The S1 step and figure 2 , providing a semiconductor substrate 101 of the first conductivity type. figure 2 is a schem...

Embodiment 2

[0110] This embodiment provides a superjunction device structure and its preparation method. Compared with Embodiment 1, the difference of this embodiment is that the germanium-silicon composition ratio of the germanium-silicon material constituting the pillar structure can also vary with the pillar structure. The depth direction changes gradually.

[0111] As an example, when the thickness of the graded epitaxial layer is 50 microns and the depth of the column structure is 42 microns, in the thickness direction, the atomic percentage of germanium is from 0.5% of the lower surface of the graded epitaxial layer 102 Gradually increase to 5% of the upper surface of the graded epitaxial layer 102 . In order to match the change of germanium content in the graded epitaxial layer, the germanium content in the column structure can also be set to gradually change along the depth direction of the column structure. For example, the germanium content is lower at the bottom of the pillar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com