Electric heating type drying box

An electric heating type, drying oven technology, applied in heating devices, local stirring dryers, lighting and heating equipment, etc., can solve the problems of unbalanced temperature, affecting heat transfer and heat transfer, and complex heating plate structure, etc. anti-stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

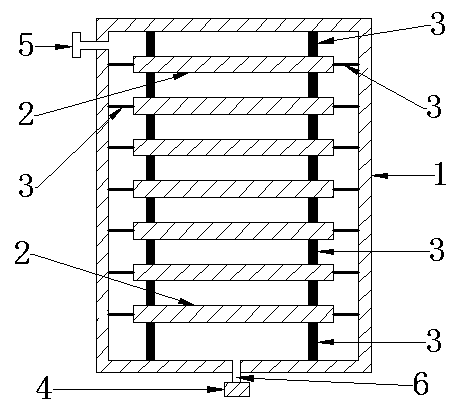

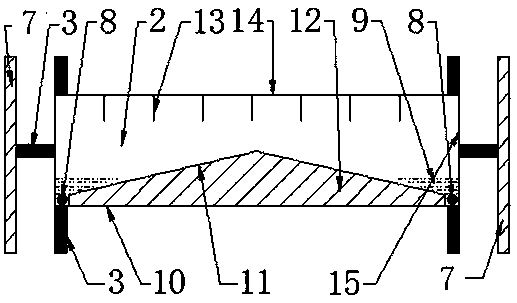

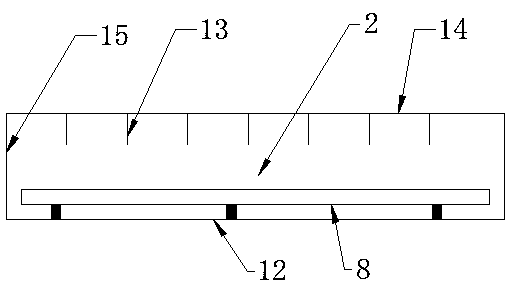

[0076] Such as figure 1 , figure 2 An electric heating type drying oven shown includes a drying oven 1, a heating device 2, a bracket 3, and a drain valve 4.

[0077] The drying box 1 has an exhaust port 5 and a drain port 6.

[0078] The box body 7 of the drying box 1 is formed by stamping, folding, and welding of steel plates, and the outer surface of the box body 7 is insulated with an insulating layer.

[0079] The door seal of the door of the drying oven 1 is sealed with a silicone rubber strip, and a window for observation is provided on the door.

[0080] The drying box 1 has a drain 6 on the bottom surface.

[0081] The drain valve 4 is installed on the drain port 6 outside the drying box 1.

[0082] After drying the materials in the drying box 1, after opening the drain valve 4, the water produced by condensation of moisture generated when the materials in the drying box 1 are dried is discharged from the drying box 1 through the drain 6.

[0083] After the drying box 1 has drie...

Embodiment 2

[0131] An electrically heated drying oven of the present invention includes a drying oven 1, a heating device 2, and a support 3.

[0132] The similarities between the combined structure of the electrically heated drying oven in the second embodiment and the electrically heated drying oven introduced in the first embodiment will not be repeated.

[0133] An electrically heated drying box of the second embodiment uses an air convection drying process to dry materials.

[0134] The drying box 1 has an exhaust port 5 and a drain port 6.

[0135] The exhaust port 5 is installed with a fan.

[0136] The moisture generated when the material in the drying box 1 is dried is discharged out of the drying box 1 through the exhaust port 5.

[0137] There is no drain valve installed on the drain port 6 of the drying box 1.

[0138] The air outside the drying box 1 directly enters the drying box 1 through the drain 6 and the air outside the drying box 1 enters the drying box 1 to carry moisture.

[0139...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com