Truss type steel reinforced concrete beam with full bolted connection and construction method

A technology of concrete beams and construction methods, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of cost impact, on-site construction process impact, and difficulty in lifting, and achieves a reduction in self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

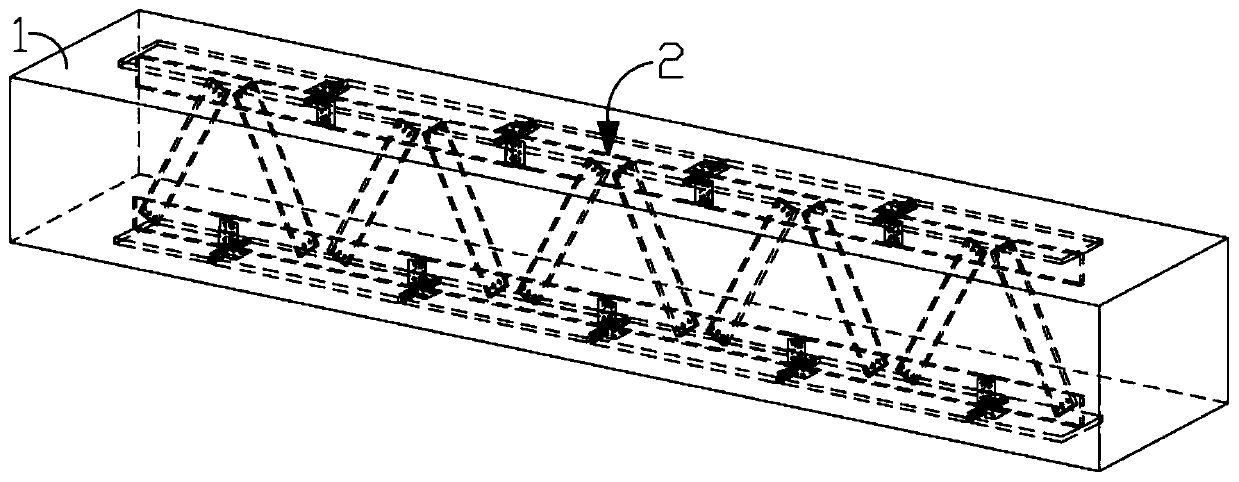

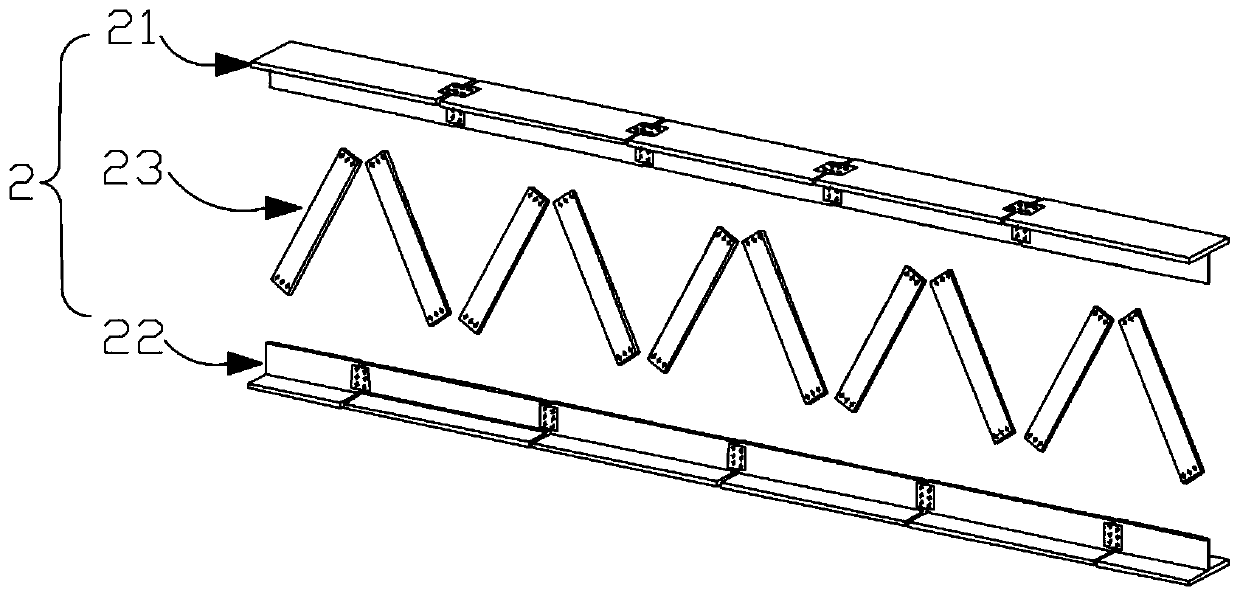

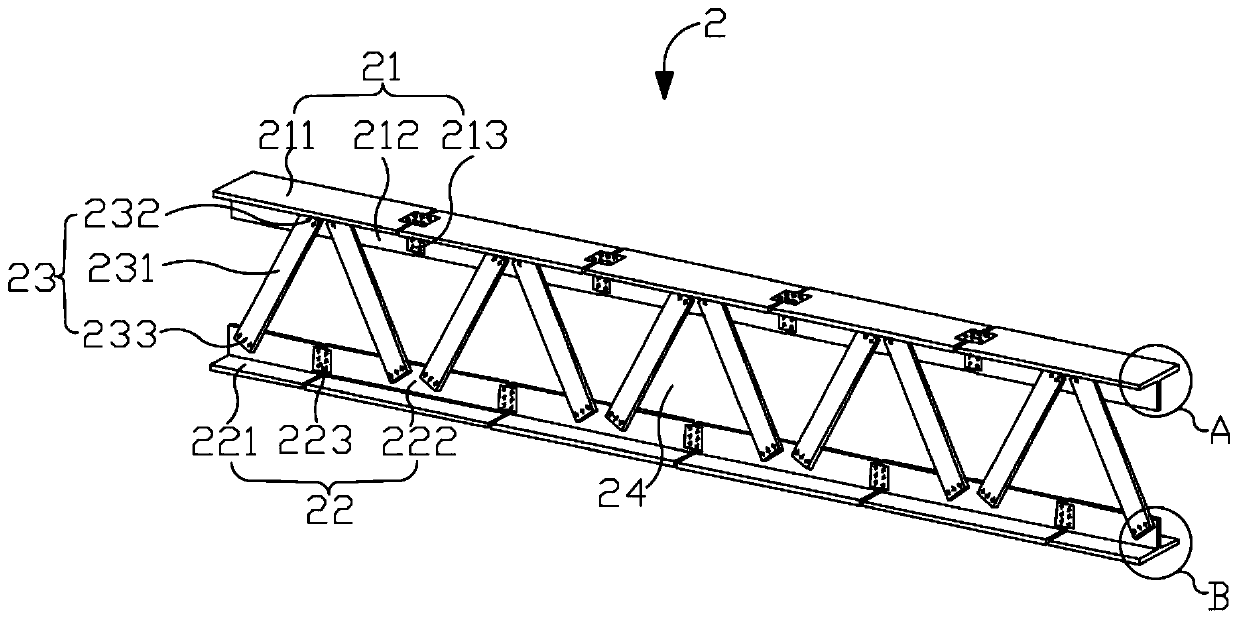

[0049] Please also refer to Figure 1 to Figure 3 , the fully bolted truss-type steel concrete beam provided by Embodiment 1 of the present invention, the truss-type steel-concrete beam includes a concrete beam body 1 and a truss-type steel 2 arranged in the concrete beam body 1, and the truss-type steel 2 includes a first steel plate 21. The second steel plate 22 and the connection assembly 23. The first steel plate 21 includes an upper flange plate 211 and a first web 212 extending downward from the upper flange plate 211. The second steel plate 22 is arranged below the first steel plate 21 and Spaced apart from the first steel plate 21, the second steel plate 22 includes a lower flange plate 221 and a second web 222 extending upward from the lower flange plate 221, and the connecting assembly 23 is connected to the first web 212 and the second web 222 .

[0050] In this way, since the section steel in the truss-type steel concrete beam is transformed from the traditional i...

Embodiment 2

[0067] see Figure 10 Embodiment 2 of the present invention provides a construction method for fully bolted truss type steel concrete beams. For the specific structure of fully bolted truss type steel concrete beams, please refer to Embodiment 1, which will not be repeated in this embodiment. The construction method of the fully bolted truss type steel concrete beam is as follows:

[0068] 201: supporting an installation platform at a preset installation position.

[0069] In this embodiment, according to the structure of the fully bolted truss-type steel-concrete beam, a matching installation platform is supported in the preset installation position, so as to facilitate the installation of the truss-type steel and the hanging formwork for the subsequent installation of the concrete beam.

[0070] 202: Elevate the first steel plate, the second steel plate and the connecting component to a preset installation position and place them on the installation platform.

[0071] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com