Underwater grouting construction system and method of straight pile outer-sleeve type jacket with first pile method

A technology of underwater grouting and jacket, which is applied in the direction of infrastructure engineering, construction, etc., can solve problems such as the sealing of easy-clogging pipe packers, affecting construction results, and damage, so as to reduce construction costs, improve grouting safety, and avoid The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

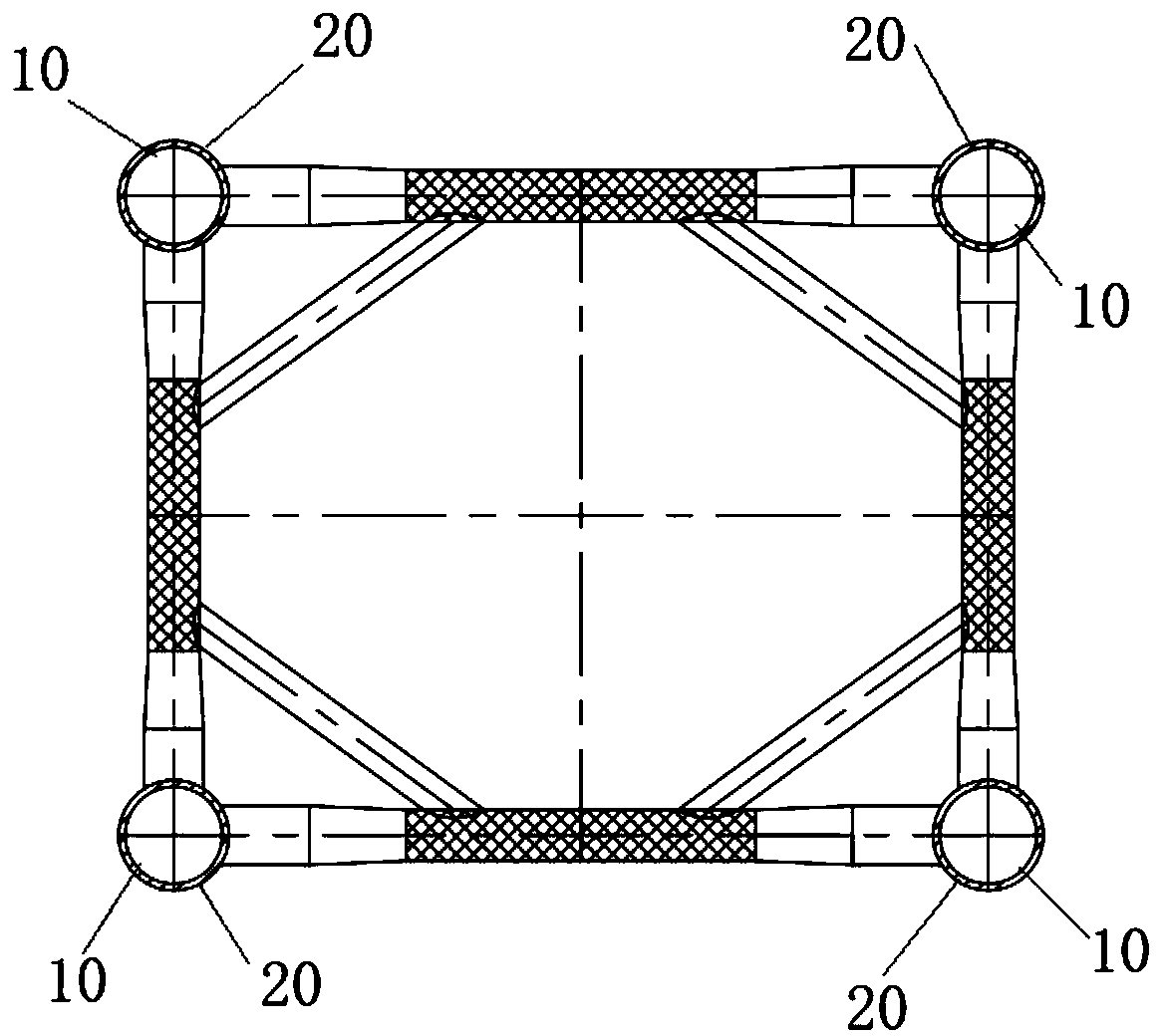

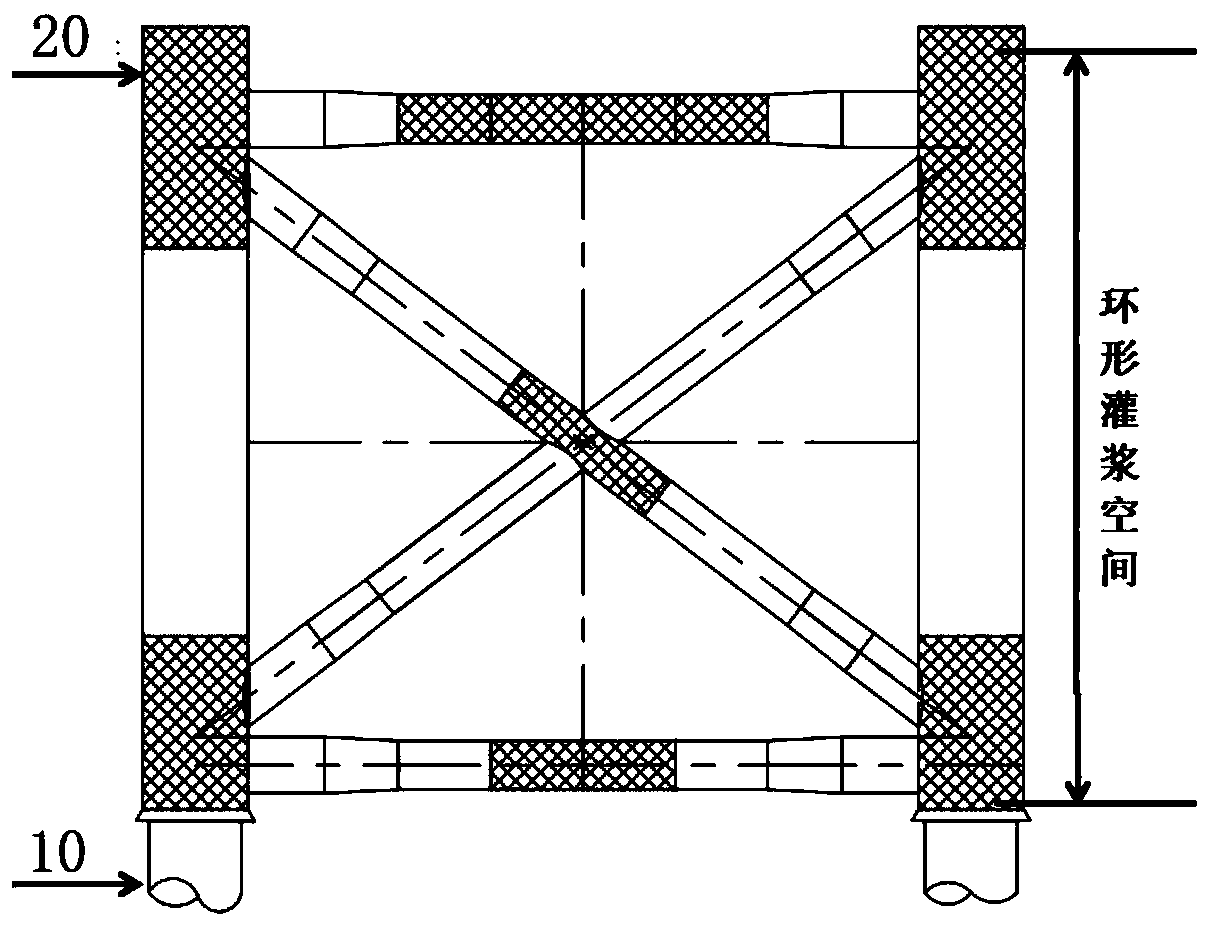

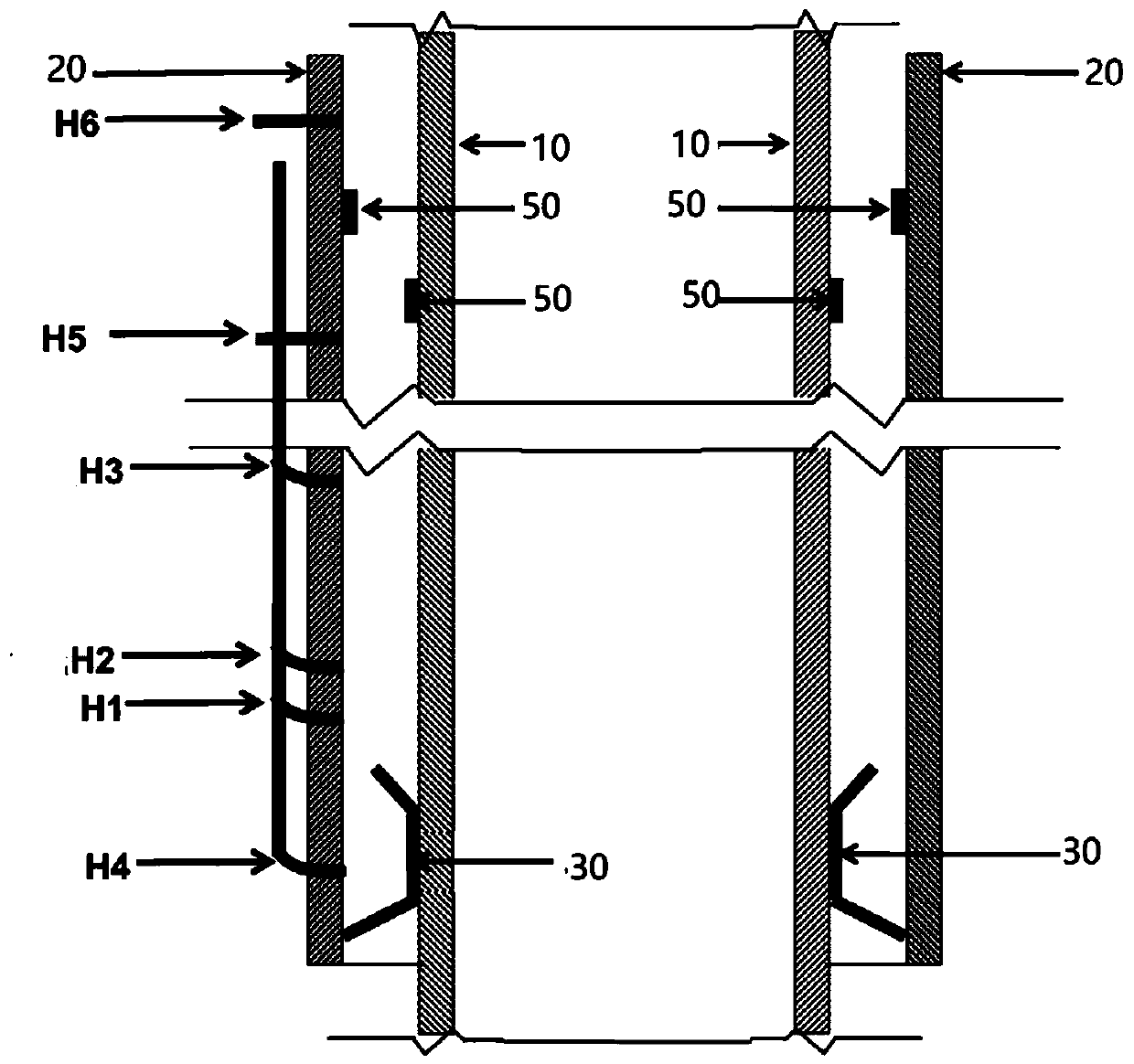

[0030] Such as Figure 1 to Figure 5 As shown, in this embodiment, the construction system for underwater grouting of the jacketed jacket 20 of the pile-first method, the system includes a steel pipe pile 10 and a jacket 20 set outside the steel pipe pile 10. An annular grouting space is formed between the pipe pile 10 and the jacket 20, wherein the steel pipe pile 10 and the jacket 20 are vertically arranged; the jacket 20 is provided with a main grouting pipe H1, a spare The grouting pipe and the back-sealing grouting pipe H5, the main grouting pipe H1, the backup grouting pipe and the back-sealing grouting pipe H5 all pass through the jacket 20 and communicate with the annular grouting space. This embodiment is applicable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com