Hub Forming Method

A wheel hub and pre-forming technology, which is applied in the direction of wheels, forming tools, metal processing equipment, etc., can solve the problems that cannot meet the needs of multiple varieties of parts, large batches, low-cost production, low material utilization rate, and large tonnage of equipment. Material utilization rate, simple process, and the effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

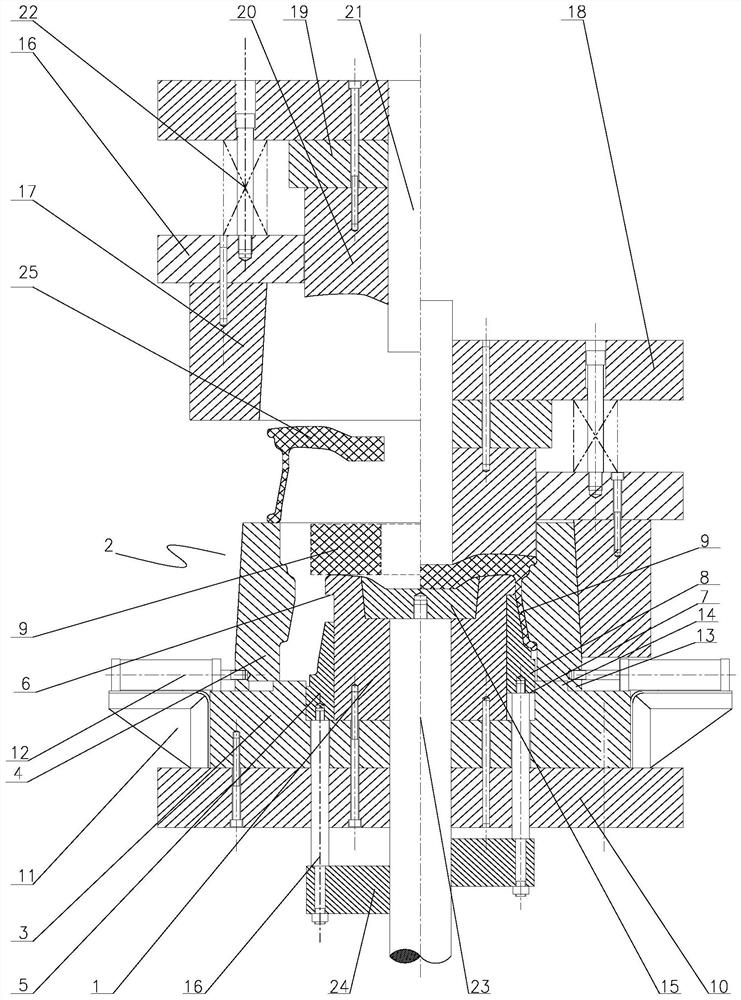

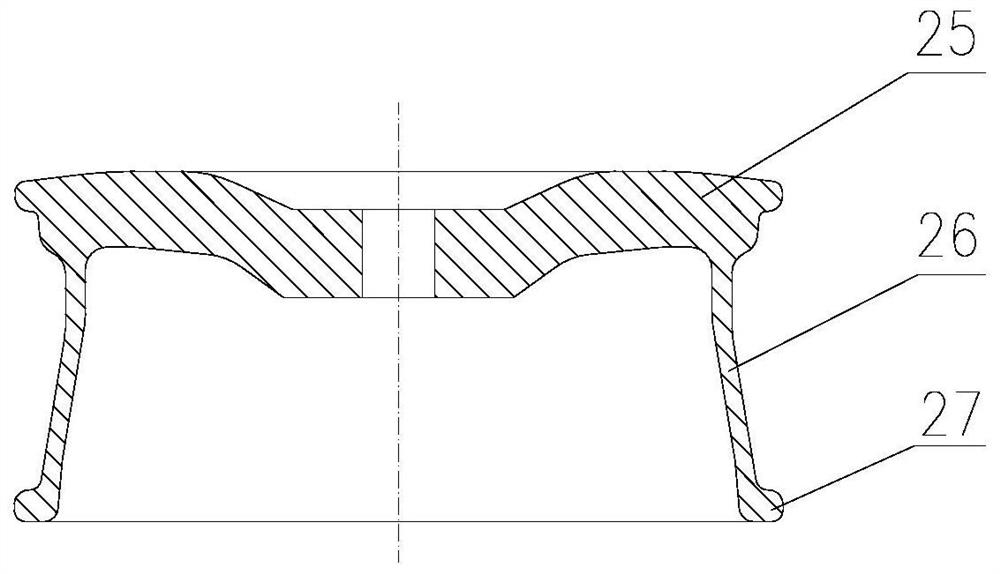

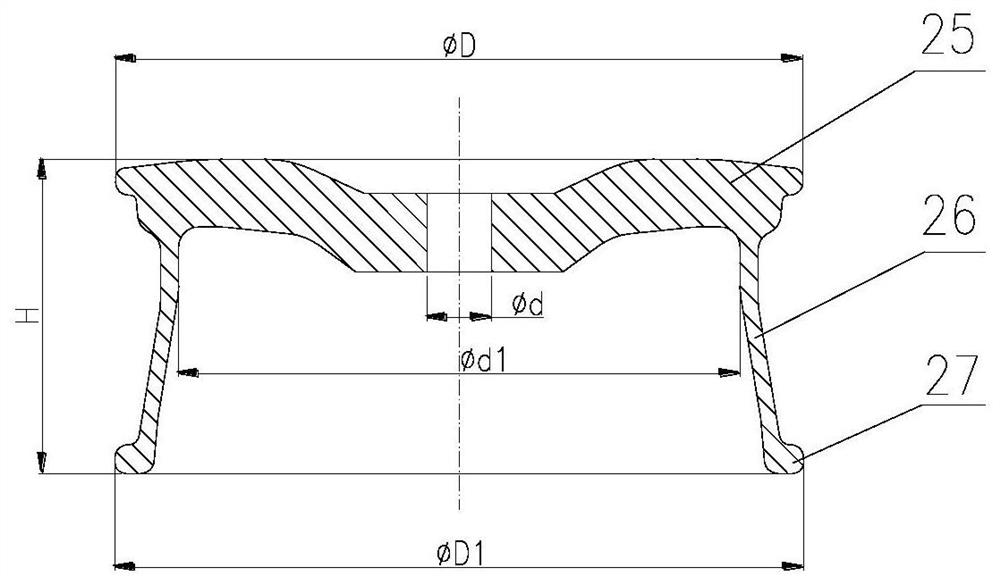

[0041] see in conjunction Figure 1 to Figure 8 As shown, according to the embodiment of the present application, the hub forming device used in the hub forming method includes an upper mold part and a lower mold part, and a hub extrusion cavity is formed between the upper mold part and the lower mold part, and the lower mold part includes a lower mold Die core 1 and a plurality of combined dies 2 arranged on the outer peripheral side of the lower die core 1, the combined dies 2 are movable along the direction approaching or away from the lower die die core 1, when the combined dies 2 are combined together, The lower mold core 1 cooperates to form the lower mold cavity.

[0042] When the wheel hub forming device is forming the wheel hub, the forming and ejection of the extrusion die can be realized through the movement of the combined die 2. When the wheel hub needs to be extruded, the combined die 2 can be controlled to move closer to the core of the lower die. 1, and make a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com