Stamping machining equipment

A technology of mechanical processing and equipment, which is applied in the field of stamping mechanical processing equipment, can solve the problems of easy bonding of stamping plates, unstable clamping of stamping plates, and affecting production and processing efficiency, so as to improve stamping quality and avoid bonded stamping board, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

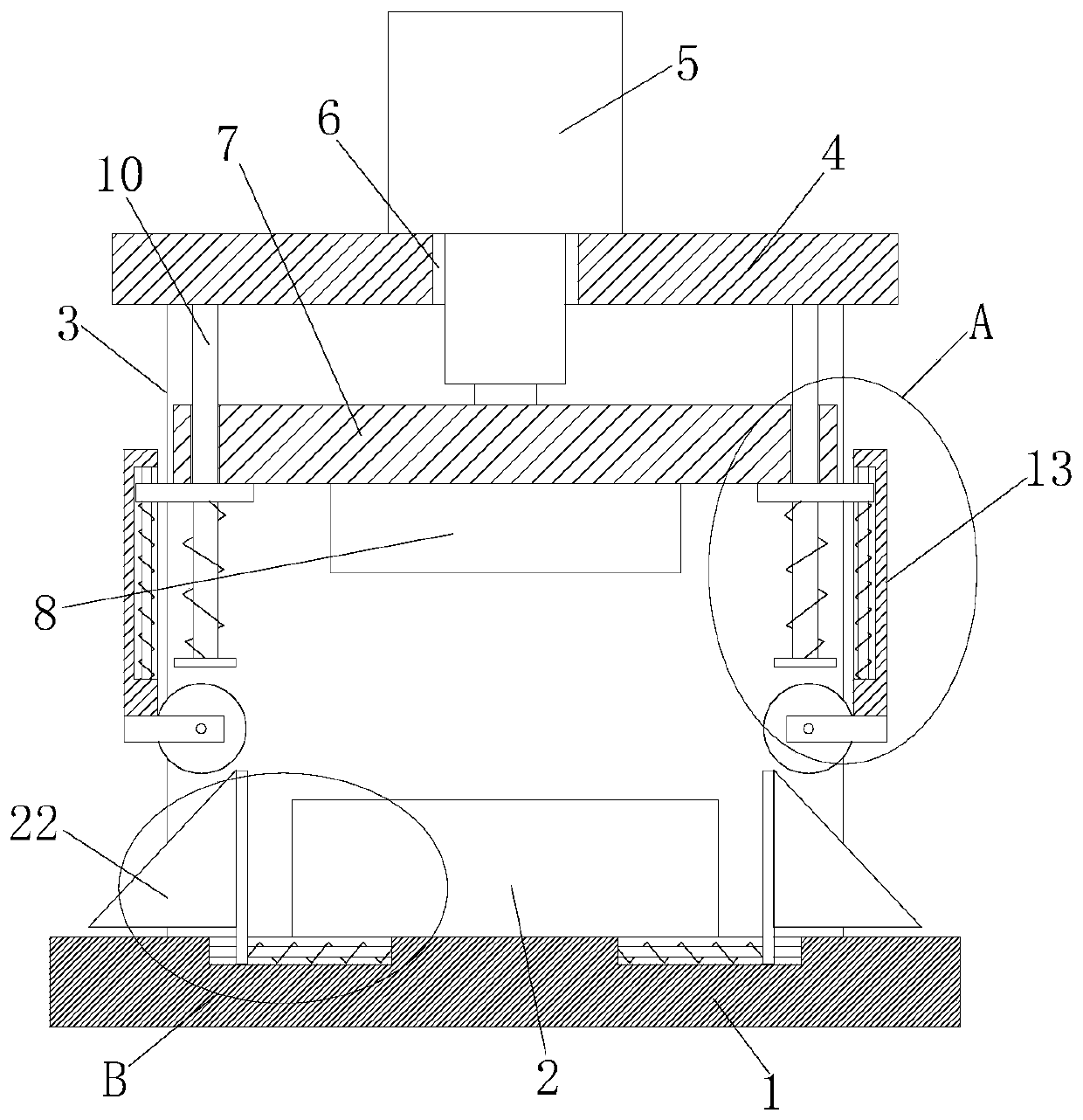

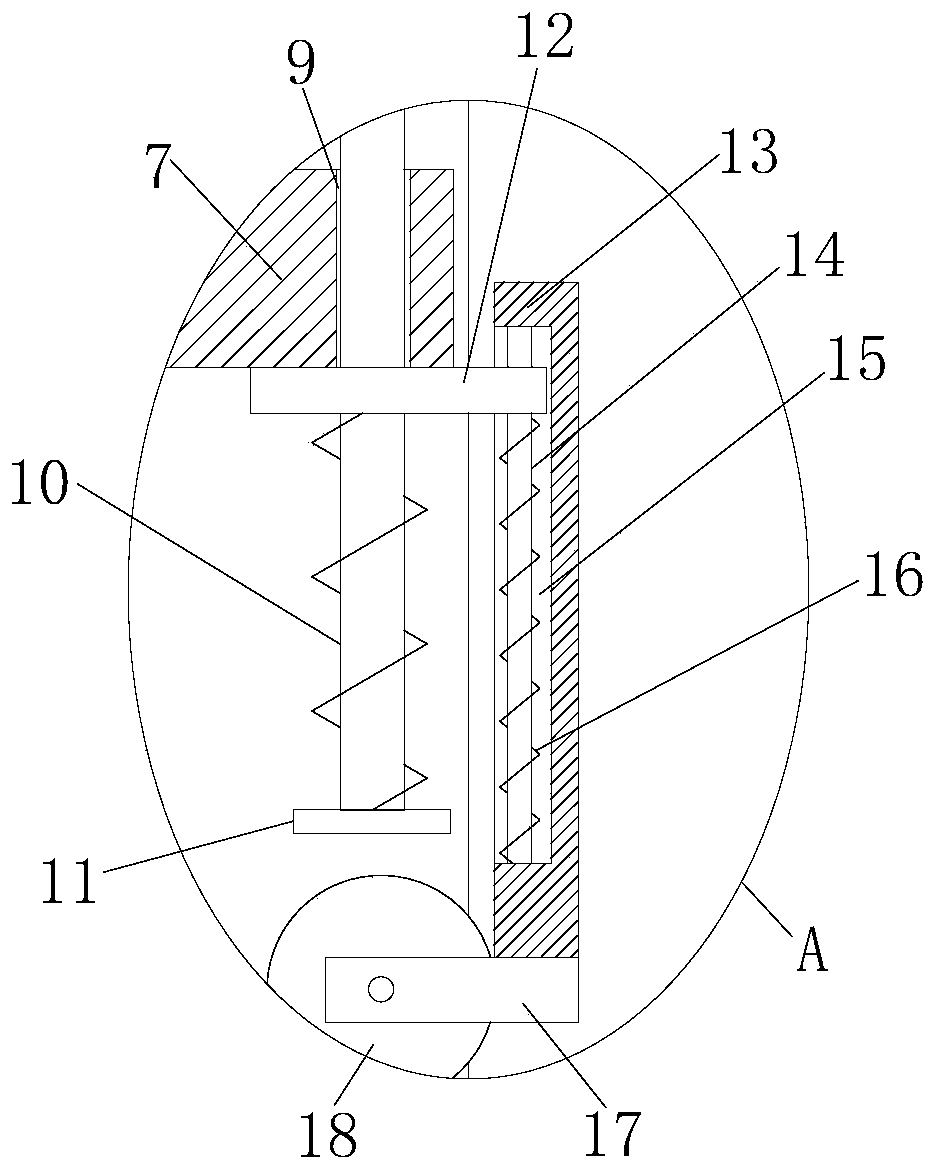

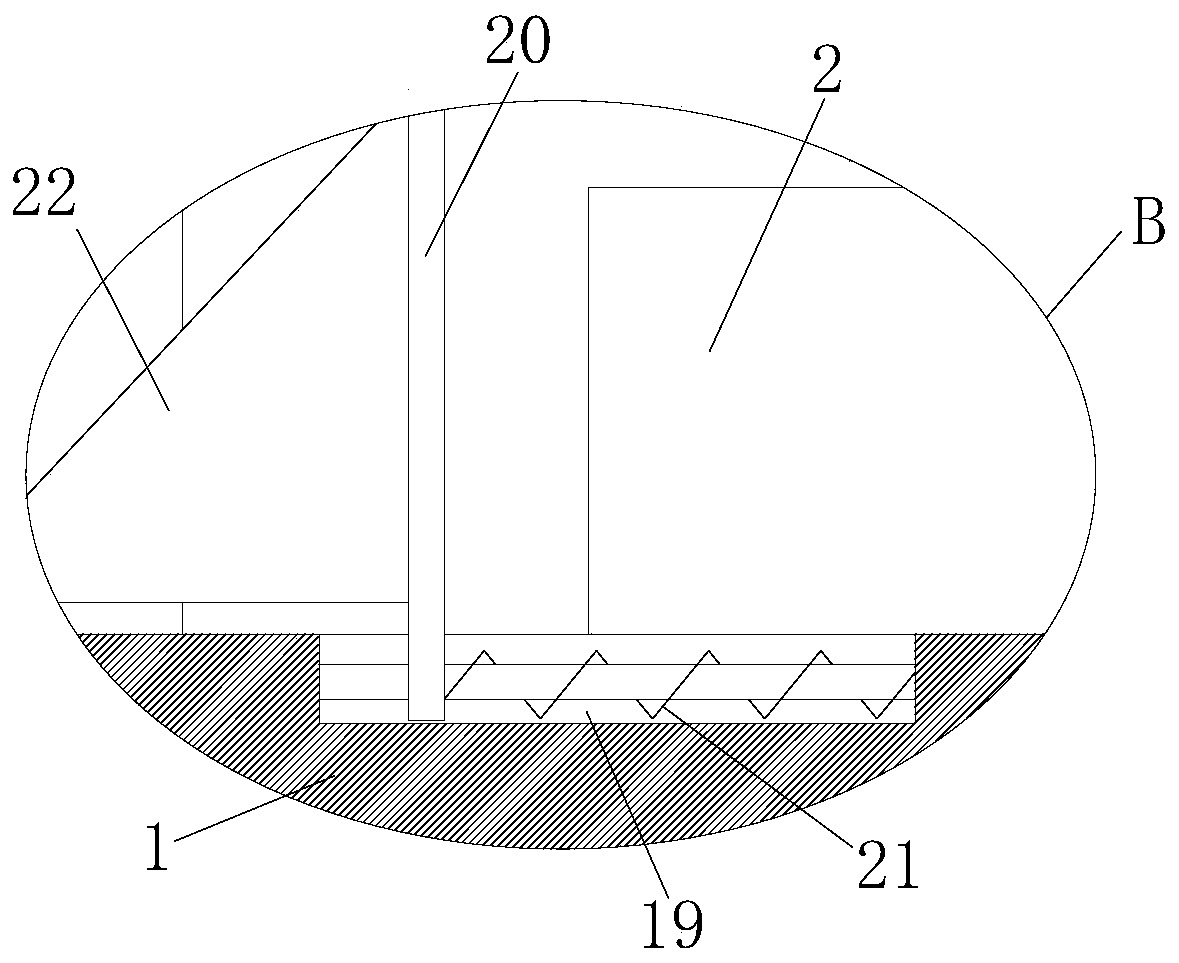

[0026] refer to Figure 1-6, a stamping machine processing equipment, including a processing table 1, the top of the processing table 1 is provided with a stamping plate 2, the top of the processing table 1 is fixedly installed with two fixed plates 3, and the tops of the two fixed plates 3 are fixedly installed with the same Top plate 4, a hydraulic cylinder 5 is fixedly installed on the top of the top plate 4, a through hole 6 is opened on the top plate 4, the piston rod of the hydraulic cylinder 5 extends through the through hole 6 to the bottom of the top plate 4 and a lifting plate 7 is fixedly installed, and the lifting plate 7 The bottom of the top plate 4 is fixedly equipped with a pressing block 8, the lifting plate 7 is located between the two fixed plates 3, the pressing block 8 is located above the punching plate 2, and the bottom of the top plate 4 is fixedly equipped with two fixed rods 10, and the lifting plate 7 is provided with Two lifting holes 9, two fixing ...

Embodiment 2

[0035] refer to Figure 1-6 , a stamping machine processing equipment, comprising a processing table 1, the top of the processing table 1 is provided with a stamping plate 2, the top of the processing table 1 is fixedly installed with two fixing plates 3 by welding, and the tops of the two fixing plates 3 are fixed by welding The same top plate 4 is installed, and the top of the top plate 4 is fixedly installed with a hydraulic cylinder 5 by welding, and a through hole 6 is opened on the top plate 4, and the piston rod of the hydraulic cylinder 5 extends through the through hole 6 to the bottom of the top plate 4 and is fixed and installed by welding Lifting plate 7 is arranged, and the bottom of lifting plate 7 is fixedly installed with briquetting 8 by welding, and lifting plate 7 is positioned between two fixed plates 3, and briquetting block 8 is positioned at the top of stamping plate 2, and the bottom of top plate 4 is fixedly installed with Two fixing rods 10, two lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com