Automatic button cell electrolyte adding device

A fully automatic, button battery technology, used in primary batteries, battery assembly machines, secondary battery manufacturing, etc., to ensure normal operation, uniform quality, and prevent interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

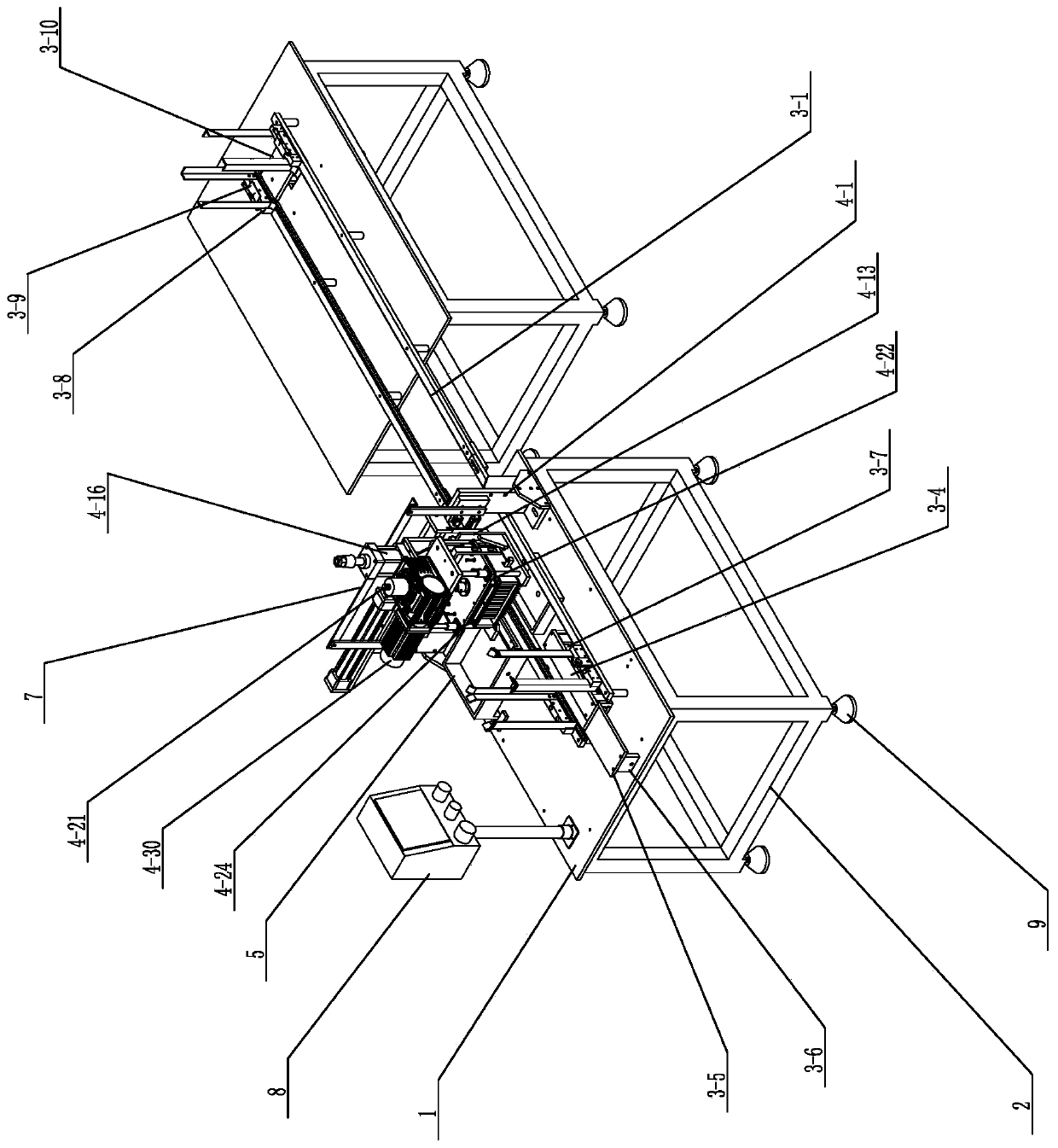

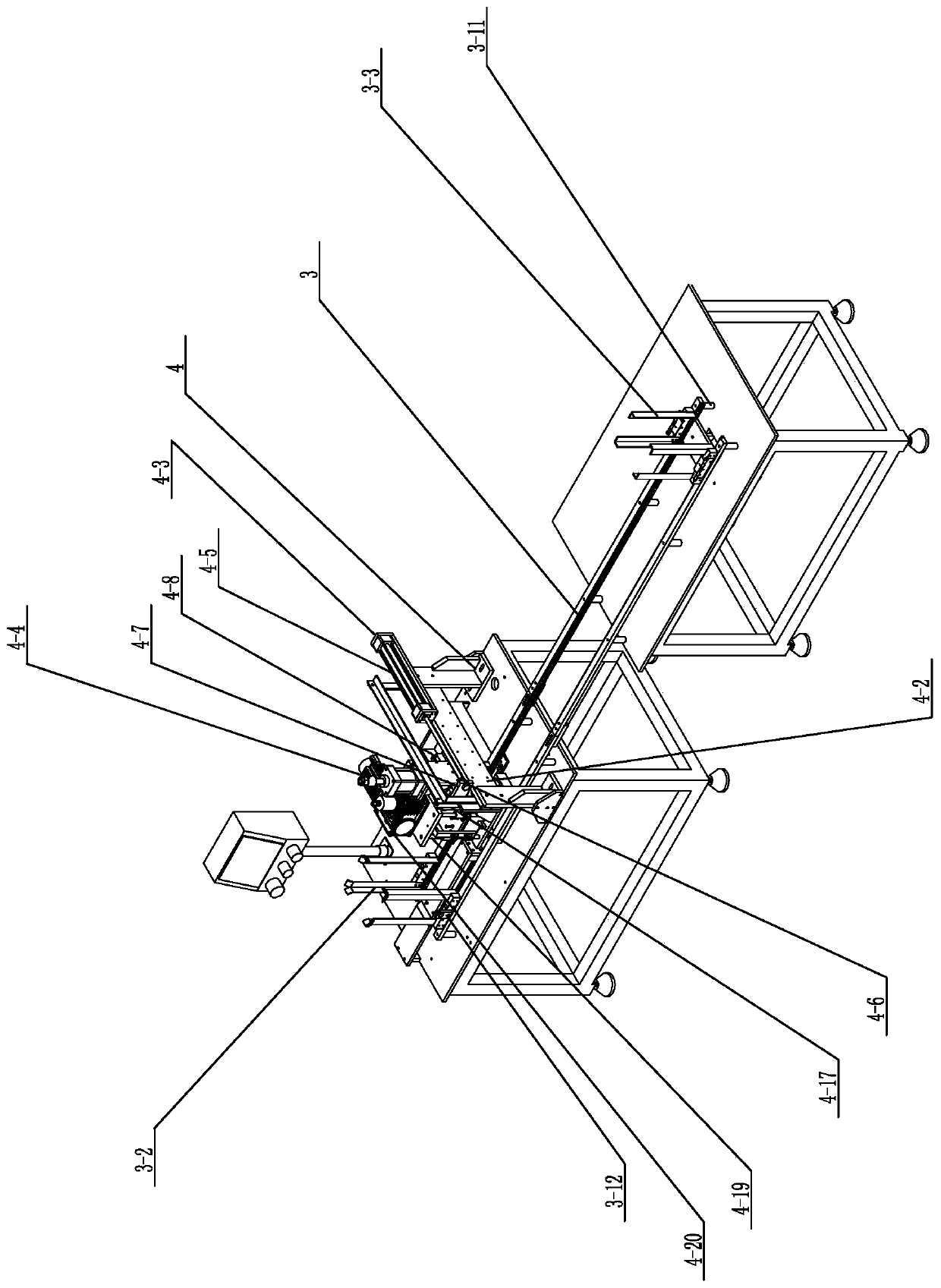

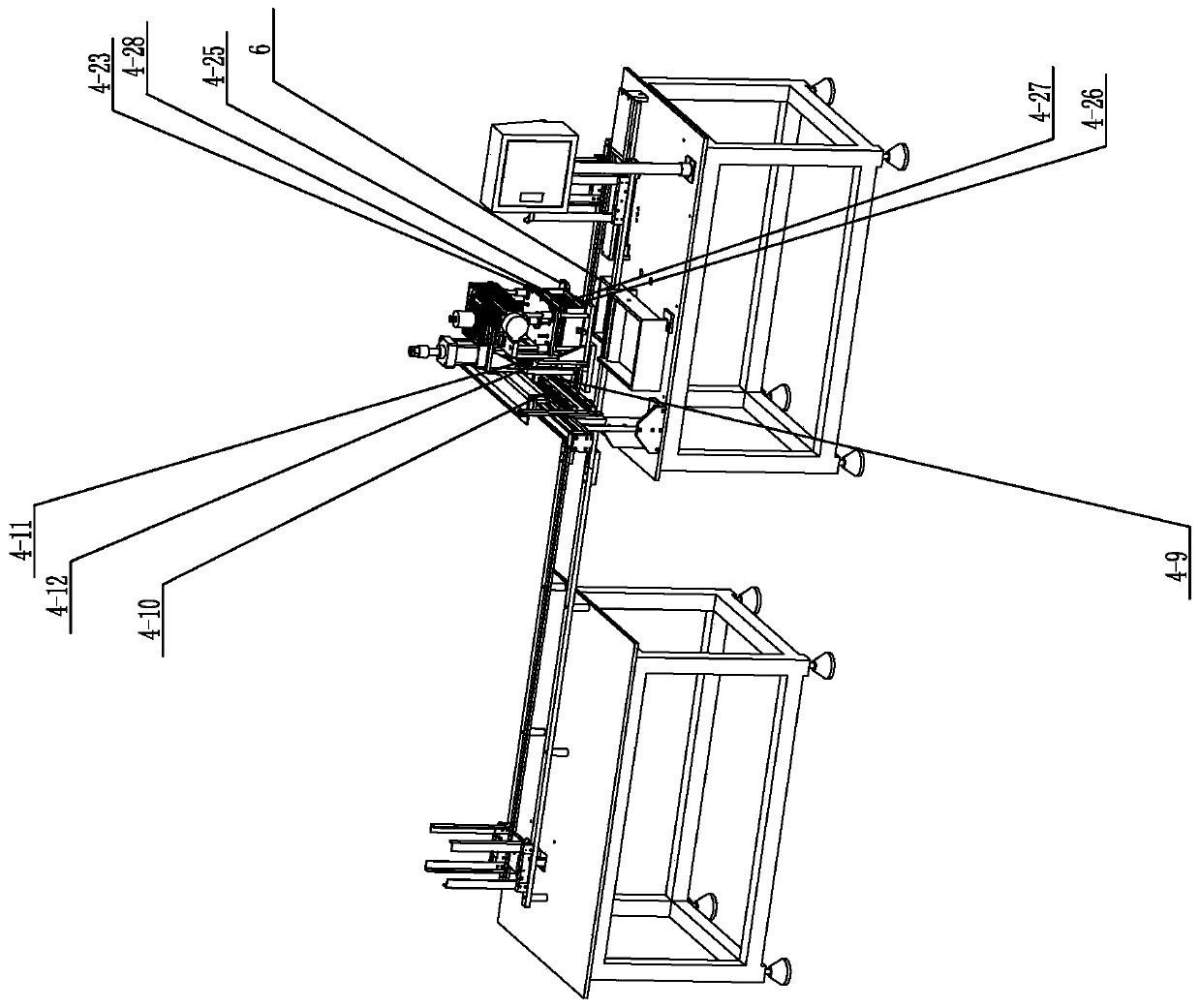

[0021] Such as figure 1Propose a kind of specific embodiment of the present invention as shown, the fully automatic button battery electrolyte addition device, comprise the workbench 1 that is rectangular shape, the bottom end of described workbench 1 is provided with frame-shaped frame 2, this implementation For example, each bottom end of the frame 2 is provided with a table adjustment balance block 9, which can make the workbench 1 flexibly applicable to various occasions, especially the occasions where the ground is uneven. The workbench 1 is provided with a material plate Conveying and stacking mechanism 3 and electrolyte automatic adding mechanism 4; the material plate conveying and stacking mechanism 3 includes a material plate conveying track 3-1 arranged on the surface of the workbench 1, and the material plate conveying track 3-1 includes two conveying rails arranged in parallel , then the horizontal distance between the two conveyor rails matches the size of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com