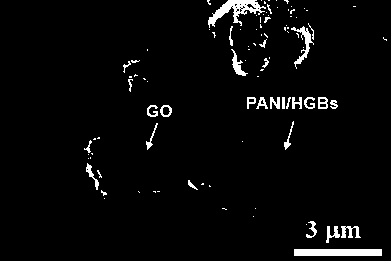

Preparation and application of polyaniline nanowire/graphene hollow sphere-graphene oxide

A graphene and hollow sphere technology is applied in the field of preparation of polyaniline nanowires/graphene hollow spheres-graphene oxide composite materials, which can solve the problems of low specific capacitance, polyaniline fracture and even falling off from graphene hollow spheres. , to achieve the effect of improving conductivity, excellent stability, and large specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of polyaniline nanowire / graphene hollow sphere-graphene oxide comprises the following steps:

[0033] 1. Preparation of graphene hollow spheres by template-directed carbon segregation

[0034] (1) Preparation of nickel nanoparticles: respectively prepare nickel chloride, 80% hydrazine hydrate and 50% sodium hydroxide solution with a molar ratio of 1:(2~4):(2~4). Dissolve in water, then add hydrazine hydrate, stir evenly, add sodium hydroxide solution, react in a water bath at 60-80 °C for 3-5 hours until gray precipitate is obtained, then wash and freeze-dry to obtain nickel nanoparticles;

[0035] (2) Use the prepared nickel nanoparticles as a template to prepare graphene hollow spheres: put 2-3 g of nickel nanoparticles into a round-bottomed flask, and add 40-60 mL of triethylene glycol, stir evenly and add 4-6 drops of 50 % sodium hydroxide solution, heated to reflux at 220-250°C for 6-12h, washed and dried the precipitate, heat-treated at 500...

Embodiment 2

[0043] The preparation method of polyaniline nanowire / graphene hollow sphere-graphene oxide composite material comprises the following steps:

[0044] The difference between this embodiment and Example 1 is: in step 3 (2), the mass of graphene oxide is 1 to 2 mg, the ultrasonic time of graphene oxide is 3 to 4 h, and the stirring time in step 3 (3) is 4 to 4 h. 6h, other is the same as specific embodiment 1;

Embodiment 3

[0046] The preparation method of polyaniline nanowire / graphene hollow sphere-graphene oxide composite material comprises the following steps:

[0047]The difference between this embodiment and Example 1 and Example 2 is: in step 3 (2), the mass of graphene oxide is 1-1.5 mg, the ultrasonic time of graphene oxide is 3.5-4 h, and in step 3 (3) The stirring time is 5~6h, and the others are the same as those in Example 1 and Example 2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com