Method and device for predicting life of mechanical component of electric drive assembly

A mechanical component and life prediction technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as inability to replace and maintain mechanical components, wear and aging of mechanical components, easy judgment errors, etc., to achieve The effect of reducing the probability of instrument maintenance delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

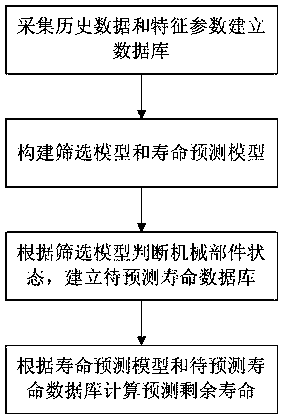

Method used

Image

Examples

Embodiment

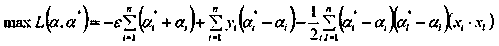

[0063] By constructing the biorthogonal wavelet SVM (Support Vector Machine, SVM) kernel function based on the second-generation wavelet transform, the life prediction model of the second-generation wavelet SVM was established, and the obtained minimum quantization error index MQE was used as the prediction feature.

[0064] First, the vibration signals of mechanical components are collected to construct a sensitive feature set. For an original vibration signal X(t), the empirical mode decomposition is used to decompose X(t) to obtain the first m eigenmode components, m is 2, 3 or 4, and 14 time domain components are calculated for each decomposed signal Statistical feature Ftime and 13 frequency-domain statistical features Ffrequency, a total of m×27 features Ftotal=[FtimeFfrequency] are obtained; from the overall feature set Ftotal, select the feature corresponding to the feature evaluation index greater than a given threshold to form the most sensitive feature Set Fsensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com