An explosion-proof floor drain used in civil air defense projects

A technology of civil air defense projects and floor drains, applied in waterway systems, buildings, water supply devices, etc., can solve the problems that explosion-proof floor drains cannot protect against irritating gases or shock waves, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

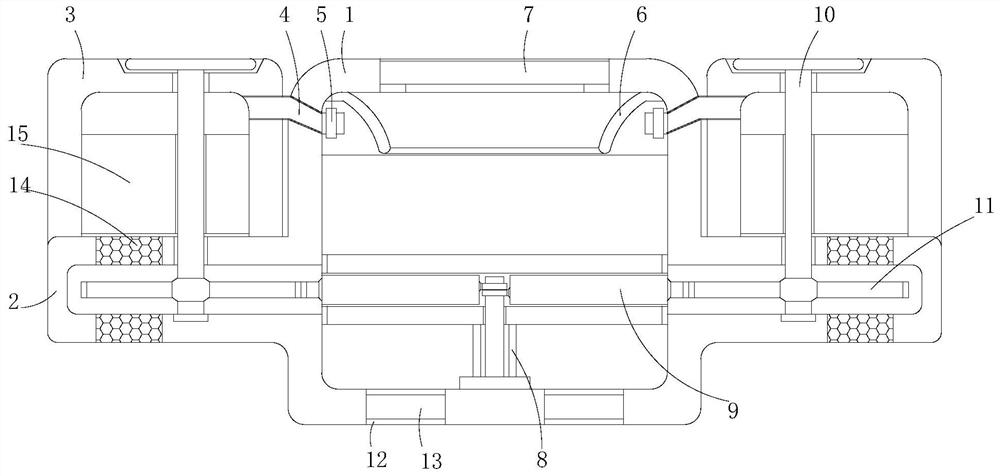

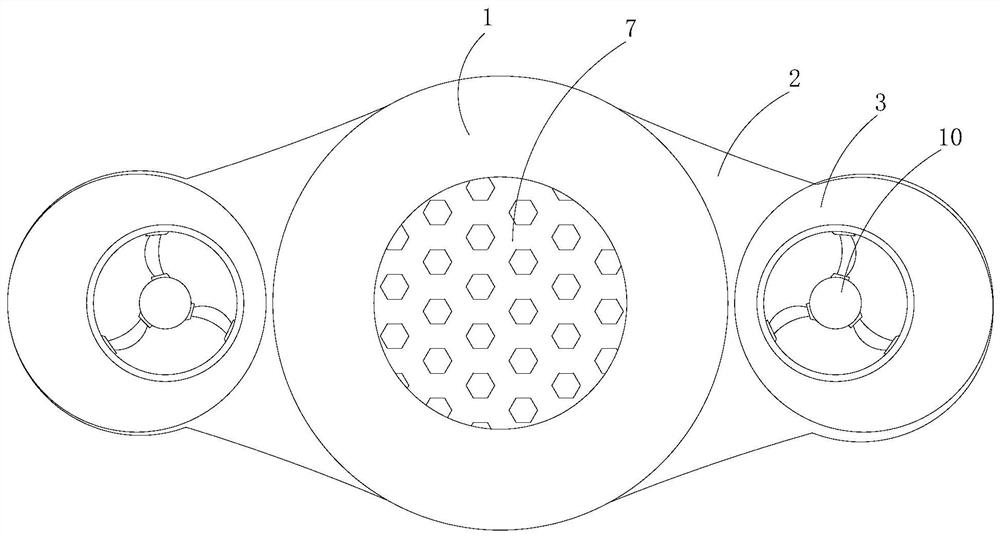

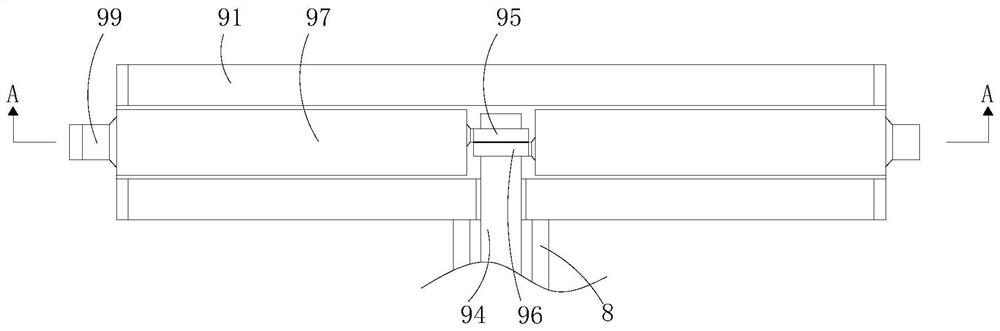

[0023] Such as Figure 1-5 As shown, the present invention provides a technical solution: an explosion-proof floor drain for civil air defense projects, including a main shell 1, two side shells 2, two side cylinders 3, two connecting pipes 4, two single Air valve 5, inner partition 6, upper filter cover 7, hollow support rod 8, intermediate isolation mechanism 9, two rotating polished rods 10, two meshing gears 11, two installation holes 12, two drainage air blocking valves 13 , ventilation holes 14 and two fiber filter layers 15, the two side shells 2 are respectively installed on the left and right sides of the main shell 1 and communicate with the main shell 1, and the two side cylinders 3 are fixedly installed on two On the top of the side shell 2, two connecting pipes 4 are fixedly connected to the two side cylinders 3 respectively, and the ends of the two connecting pipes 4 respectively pass through the left and right sides of the main shell 1 and extend to the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com