High impact modified polystyrene material for air conditioner inner unit shell and preparation method of material

A polystyrene and air-conditioning internal unit technology, applied in the field of polymer materials, can solve the problems of poor quality of PP material products, restricting long-term development, and easy yellowing of materials, so as to reduce procurement costs, improve processing fluidity, and soften point Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

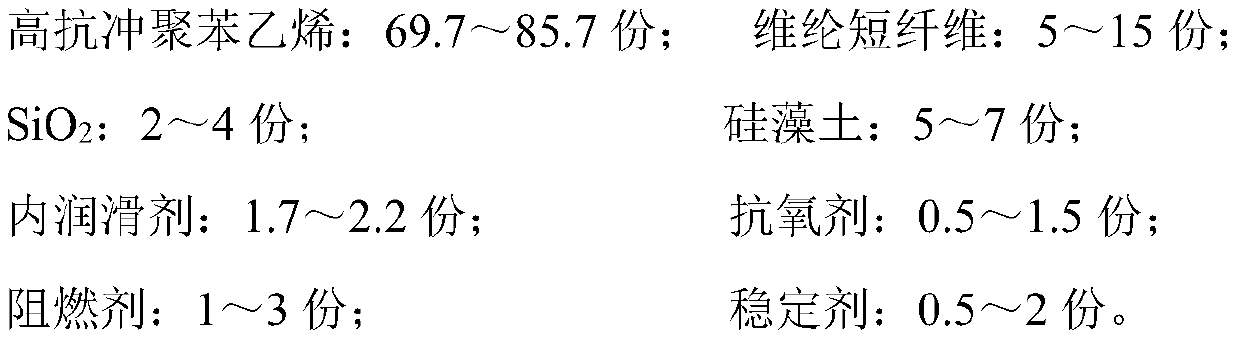

[0046] A high-impact modified polystyrene air-conditioning inner machine casing material, which is made of the following components in parts by weight:

[0047]

[0048] The internal lubricant is selected from solid paraffin.

[0049] The antioxidant is N, N'-di-β-naphthyl-p-phenylenediamine (DNP).

[0050] Described flame retardant selects Al(OH) 3 , 4ZnO·B 2 o 3 ·H 2 O.

[0051] The stabilizer is selected from 2,6-tertiary butyl-4-methylphenol, didodecyl alcohol ester, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide.

[0052] A preparation method of a high-impact modified polystyrene air conditioner inner unit shell material, comprising the following steps:

[0053] 1. Pretreatment

[0054] 1. SiO2 2 : Dry in a blower dryer at 150°C for 30 minutes, and wait for natural cooling to room temperature before use. The main purpose is to remove the water in it;

[0055] 2. Diatomite: Since diatomite contains a lot of water and organic matter, it needs to be dried in a ...

Embodiment 2

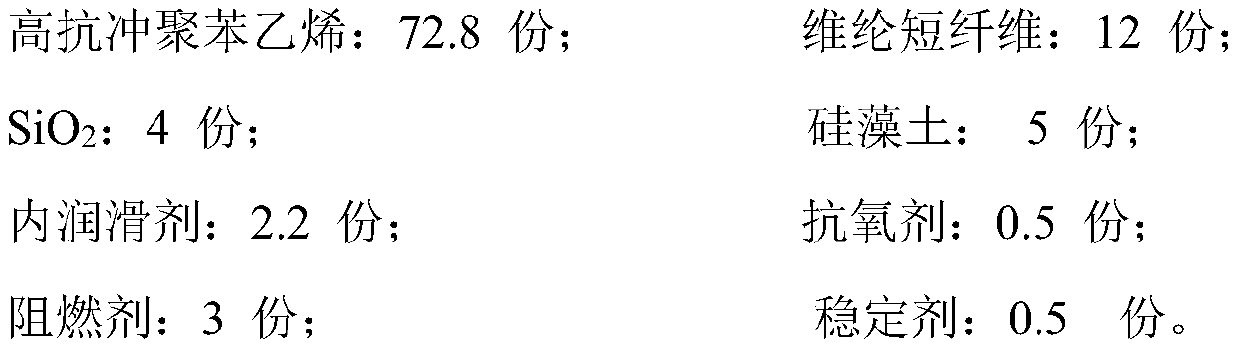

[0064] A high-impact modified polystyrene air-conditioning inner machine casing material, which is made of the following components in parts by weight:

[0065]

[0066] The internal lubricant is selected from solid paraffin.

[0067] The antioxidant is N, N'-di-β-naphthyl-p-phenylenediamine (DNP).

[0068] The flame retardant selection 4ZnO·B 2 o 3 ·H 2 O, Mg(OH) 2 .

[0069] The stabilizer is selected from tetrakis[B-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and trioctyl ester.

[0070] A preparation method of a high-impact modified polystyrene air conditioner inner unit shell material, comprising the following steps:

[0071] 1. Pretreatment

[0072] 1. SiO2 2 : Dry in a blower dryer at 160°C for 30 minutes, and wait for natural cooling to room temperature before use. The main purpose is to remove the moisture;

[0073] 2. Diatomite: Since diatomite contains a lot of water and organic matter, it needs to be dried in a high-temperatur...

Embodiment 3

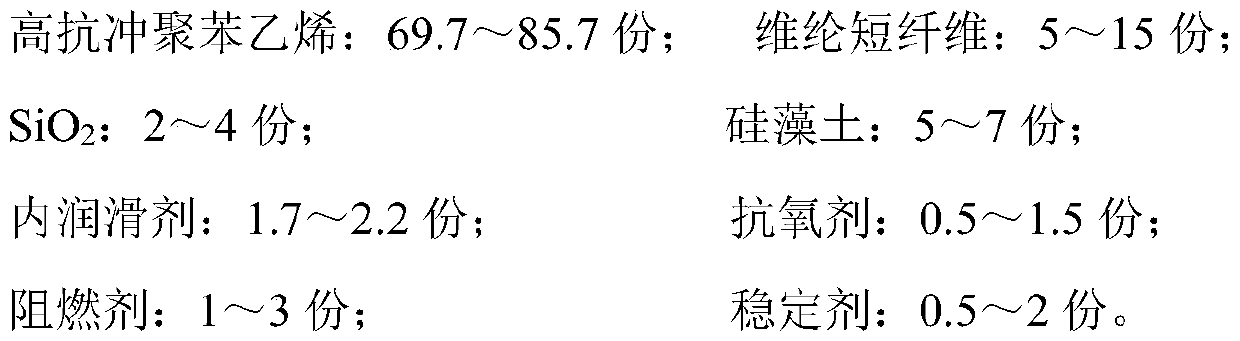

[0082] A high-impact modified polystyrene air-conditioning inner machine casing material, which is made of the following components in parts by weight:

[0083]

[0084] The internal lubricant is selected from solid paraffin.

[0085] The antioxidant is N, N'-di-β-naphthyl-p-phenylenediamine (DNP).

[0086] Described flame retardant selects Mg(OH) 2 、Al(AC) 2 .

[0087] Described stabilizing agent is selected from diphenylamine, dihydroquinoline.

[0088] A preparation method of a high-impact modified polystyrene air conditioner inner unit shell material, comprising the following steps:

[0089] 1. Pretreatment

[0090] 1. SiO2 2 : Dry in a blower dryer at 180°C for 40 minutes, and wait for natural cooling to room temperature before use. The main purpose is to remove the moisture;

[0091] 2. Diatomite: Since diatomite contains a lot of water and organic matter, it needs to be dried in a high-temperature oven at 480°C for 160 minutes, and it will be used after coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com