Thermoplastic vulcanized rubber nano composite material and preparation method thereof

A nano-composite material, thermoplastic vulcanization technology, applied in the field of nano-composite materials, can solve the problems of polyamide not entering the interlayer in time, product performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

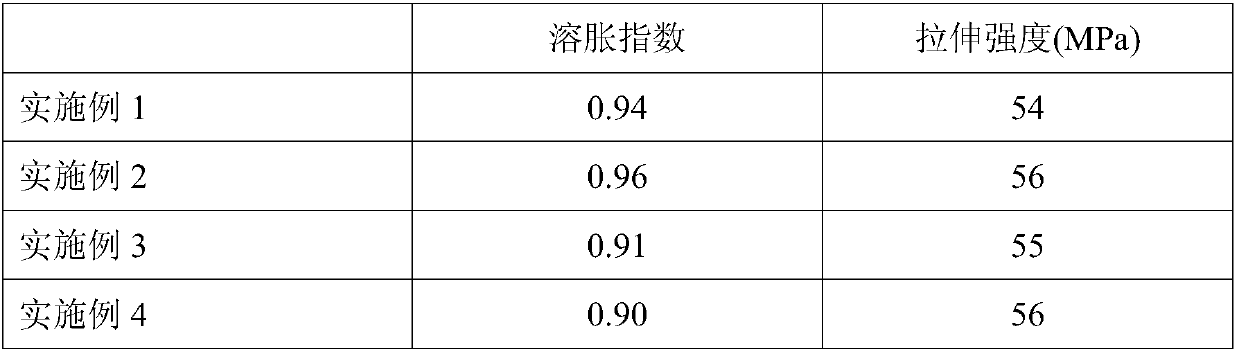

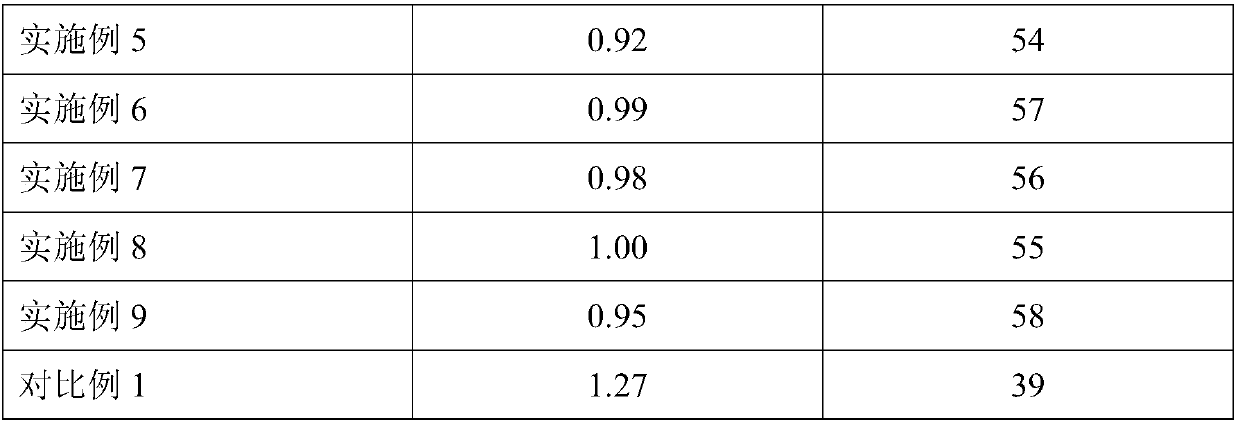

Examples

Embodiment 1

[0086] The thermoplastic vulcanizate described in this embodiment is acrylic rubber / PET, wherein rubber-to-plastic ratio is 70 / 30, the mass ratio of nanometer material and thermoplastic vulcanizate is 15:100, the liquid medium that adopts is water, and the auxiliary agent that adopts is polysorbate Esters and their oligomers, the nano-materials used are nano-praseodymium oxide, and the nano-composite materials are prepared according to the following method:

[0087] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 5.5g / min for continuous stirring and disperse evenly, and the weight ratio of liquid medium to nanomaterials is 11:1;

[0088] (2) Add additives to the continuous stirring solution of step (1) in batches or at a time at a speed of 0.1g / min to obtain a paste, the consistency of which is 30mm, and the additives and nanomaterials The weight ratio is 2:1;

[0089] (3) mixing the paste obtained in step (2) with thermoplastic vulcanizate to...

Embodiment 2

[0094] In this embodiment, the thermoplastic vulcanizate is acrylic rubber / PET, wherein the rubber-to-plastic ratio is 20 / 80, the mass ratio of nanomaterials to thermoplastic vulcanizate is 10:100, and the liquid medium used is propionitrile and water, propionitrile The mass ratio with water is 1:6, the additives adopted are tragacanth gum and safflower gum, the weight ratio is 1:2, the nanomaterial used is nano-zinc oxide, and the nanocomposite material is prepared according to the following method:

[0095] (1) Stir the liquid, and at the same time add nanomaterials at a speed of 20g / min for continuous stirring to disperse evenly, and the weight ratio of the liquid medium to the nanomaterials is 100:1;

[0096] (2) Add auxiliary agent to the continuous stirring solution of step (1) with the speed of 5g / min, obtain paste, the consistency of described paste is 42mm, and the weight ratio of described auxiliary agent and nano material is 10 :1;

[0097] (3) mixing the paste obt...

Embodiment 3

[0102] In this embodiment, the thermoplastic vulcanizate is acrylic rubber / PET, wherein the rubber-to-plastic ratio is 50 / 50, the mass ratio of nanomaterials to thermoplastic vulcanizate is 1:10, the liquid medium used is water, and the auxiliary agent used is rosin Amine-ethylene oxide polycondensate, the nano-materials used are nano-titanium dioxide and nano-alumina, the mass ratio is 8:2, and the nano-composite material is prepared according to the following method:

[0103] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 0.01g / min for continuous stirring to disperse evenly, and the weight ratio of liquid medium to nanomaterials is 0.1:1;

[0104] (2) Add additives to the continuous stirring solution of step (1) at a speed of 15g / min to obtain a paste, the consistency of the paste is 39mm, and the weight ratio of the additives to nanomaterials is 30 :1;

[0105] (3) mixing the paste obtained in step (2) with thermoplastic vulcanizate to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Consistency | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com