Method for determining threshold value of multi-working-system three-phase induction motor protection system

An induction motor and protection system technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problem that the action value of the protection control system does not allow the motor, etc., and achieve the effect of reducing production costs, realizing utilization, and reducing economic investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

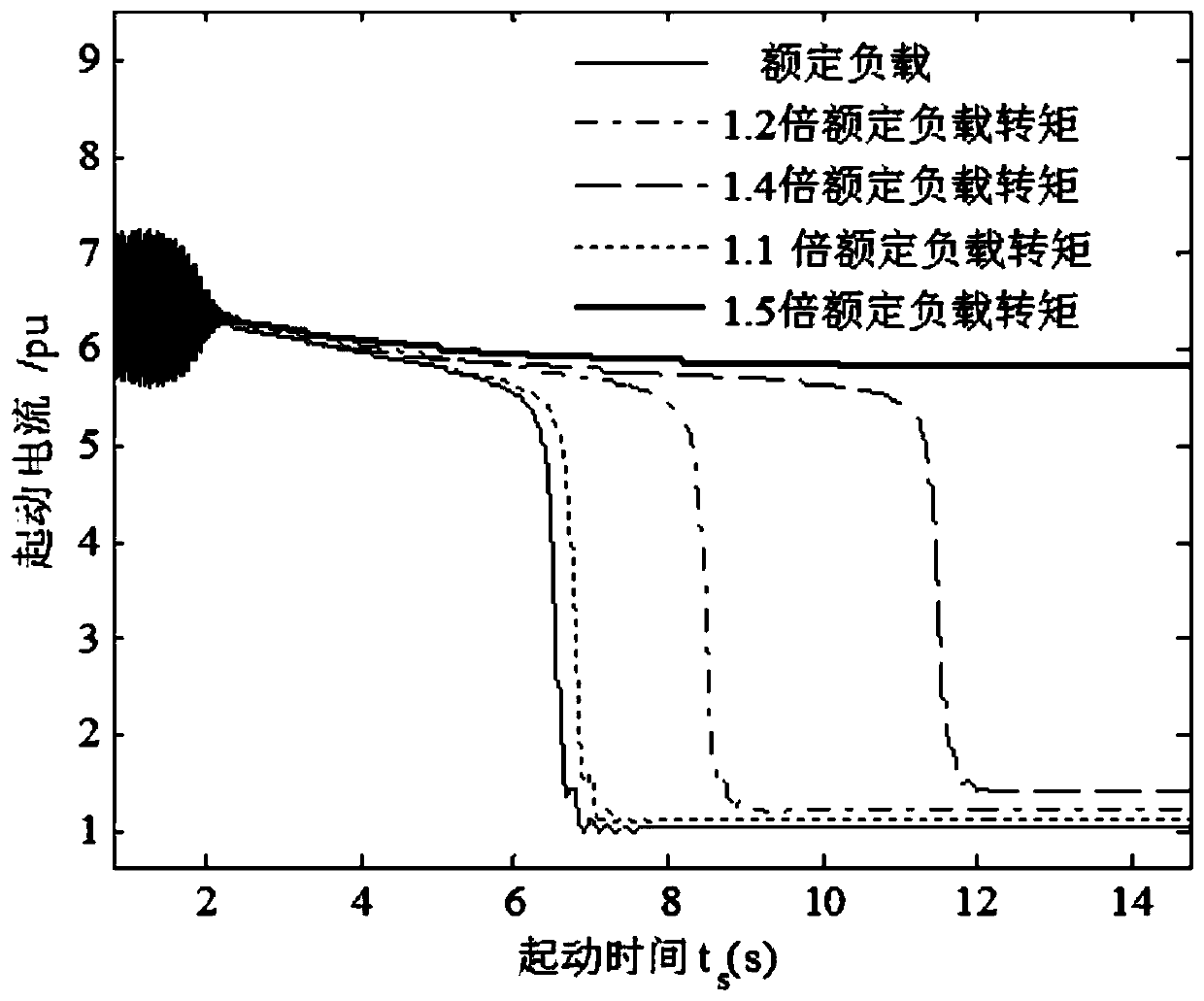

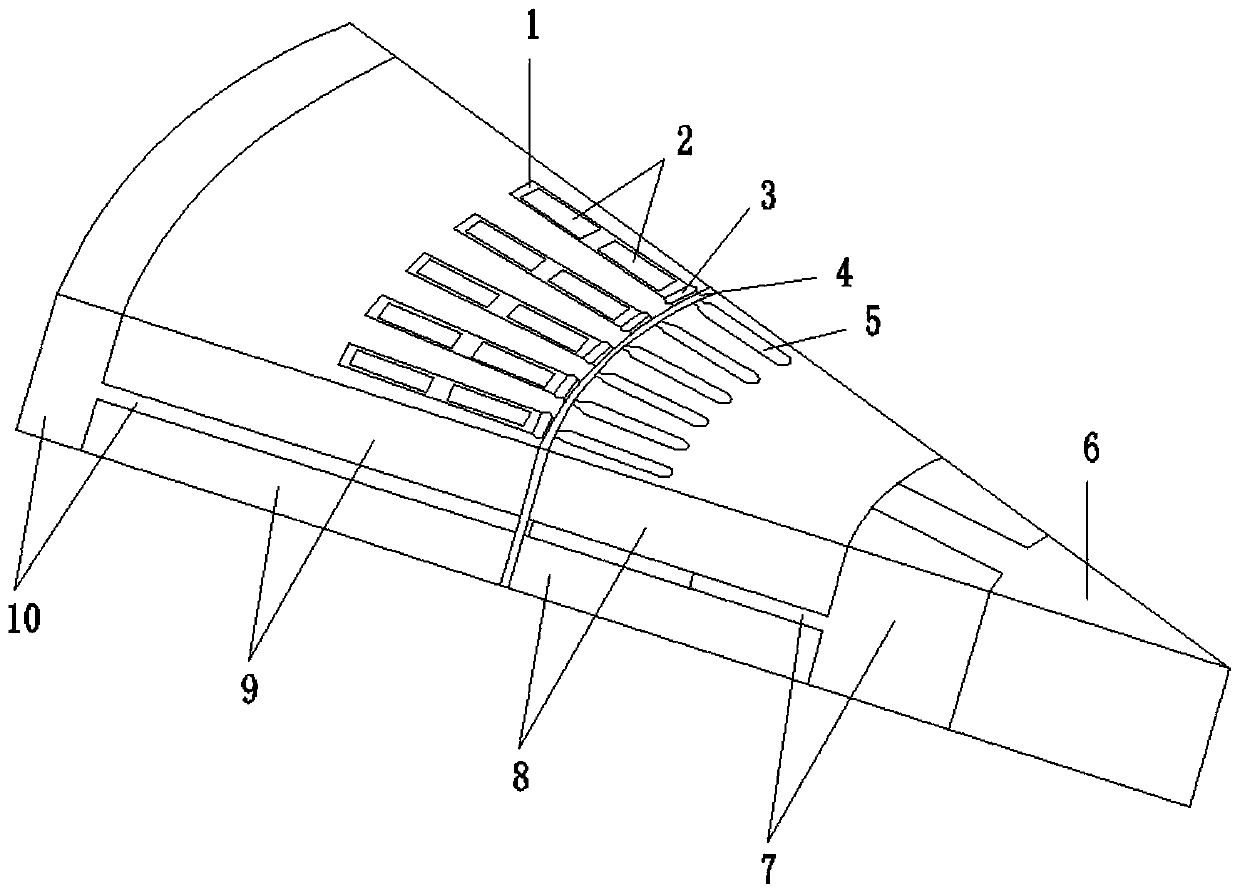

[0033] Embodiment 1: as Figure 1 to Figure 3 As shown, the motor analyzed in this embodiment is a medium-sized high-voltage three-phase induction motor, and the rated power is 2500kW under the S1 working system. The stator and rotor of the motor adopt air-to-air cooling.

[0034] Step A: Determine the overload capacity of the motor according to the calculation results of the starting characteristics of the motor. When the load torque of the motor described in this embodiment reaches 1.5 times the rated load torque, the motor will stall, resulting in a long-term maintenance of a large starting current in the motor winding, and the motor will not start reliably. Therefore, when the motor is overloaded, the overload capacity of the motor should be calculated first. According to the motor load torque and the flywheel torque of the load system, the electromagnetic torque generated by the electromagnetic induction in the motor is calculated by the formula (1), and the change of t...

Embodiment 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, the motor is a closed three-phase induction motor, and the rated power is 110 kW under the S1 working system.

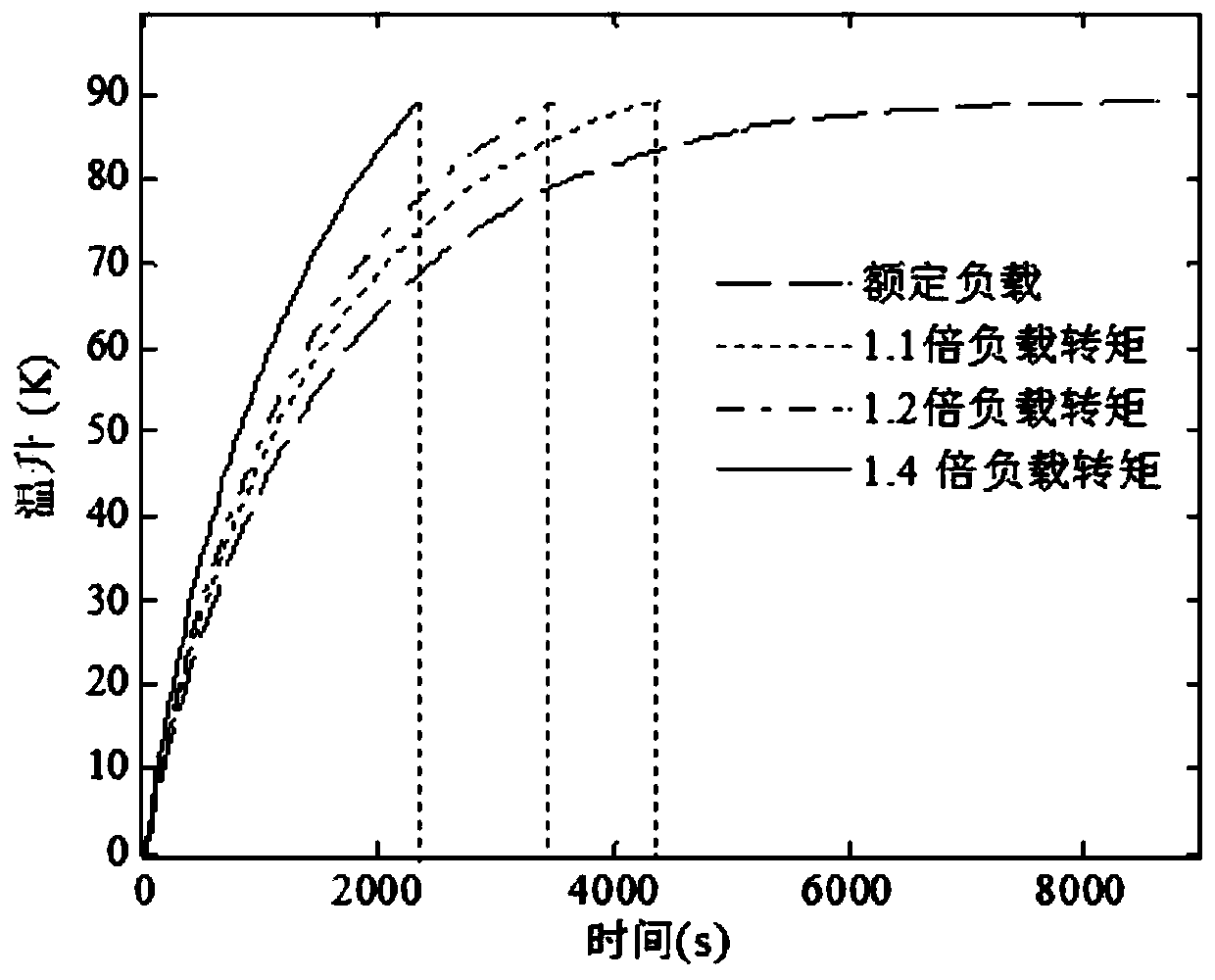

[0047] According to the collected temperature rise, when the continuous duty three-phase induction motor in this embodiment is driven by 1.1 times, 1.2 times, 1.3 times, 1.4 times and 1.5 times the rated load, the allowable longest short-term overload running time is respectively: 15 minutes, 19 minutes, 25 minutes, 36 minutes and 60 minutes.

[0048] The rated current of the three-phase induction motor in this embodiment is 115A under continuous duty. The calculation shows that when the motor drives 1.1 times, 1.2 times, 1.3 times, 1.4 times and 1.5 times the rated load for short-term operation, the rated current of the motor is: 128.5A, 139A, 150.5A, 161.8A and 173.3A . If the setting of the overload protection is consistent with the rated operating current of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com