Emptying stop valve provided with noise reduction labyrinth sleeve

A labyrinth sleeve and stop valve technology, applied in the field of stop valves, can solve the problems of air defense stop valves such as high noise, high cost of noise reduction equipment, and unfavorable large-scale use, so as to improve the life of the valve, eliminate adverse consequences, and effectively control the flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

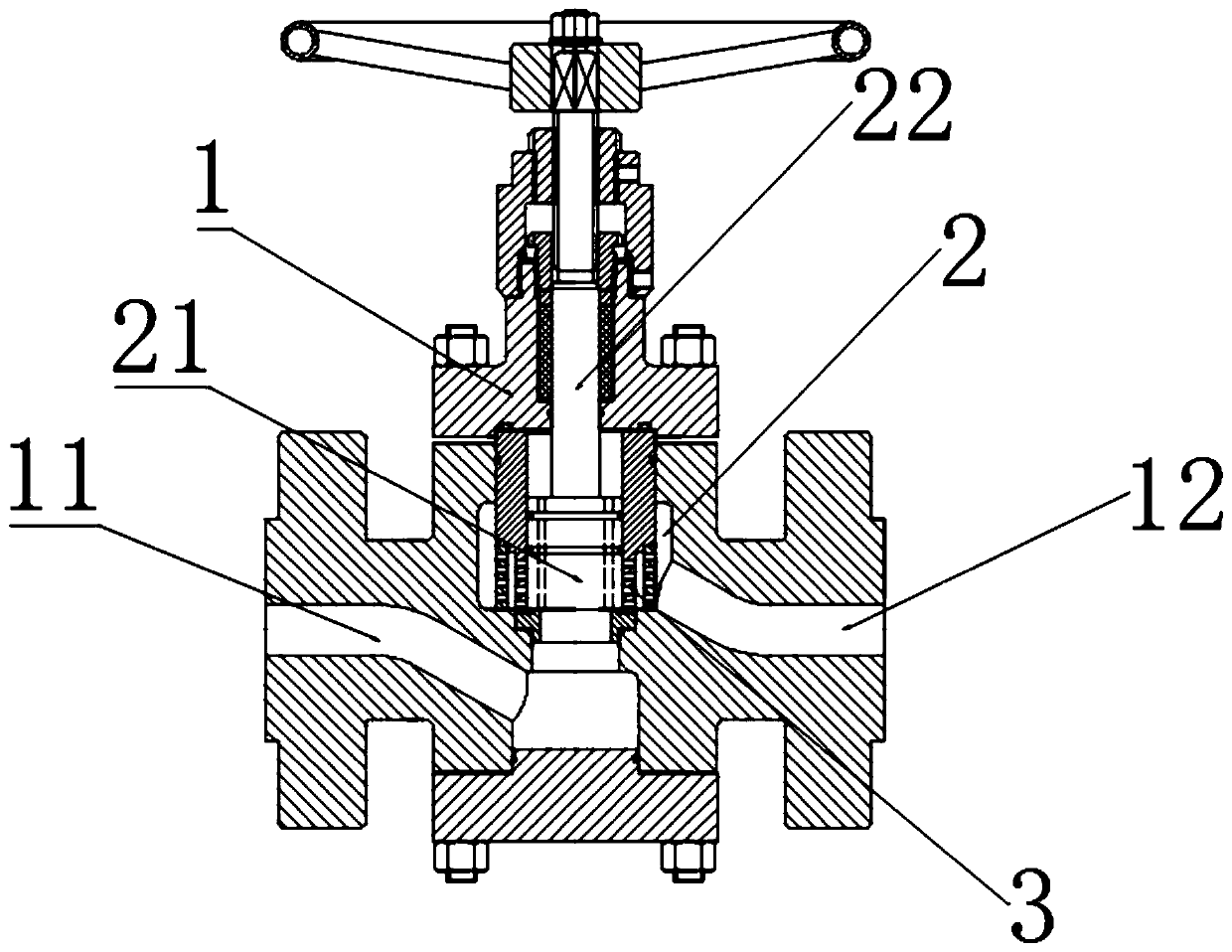

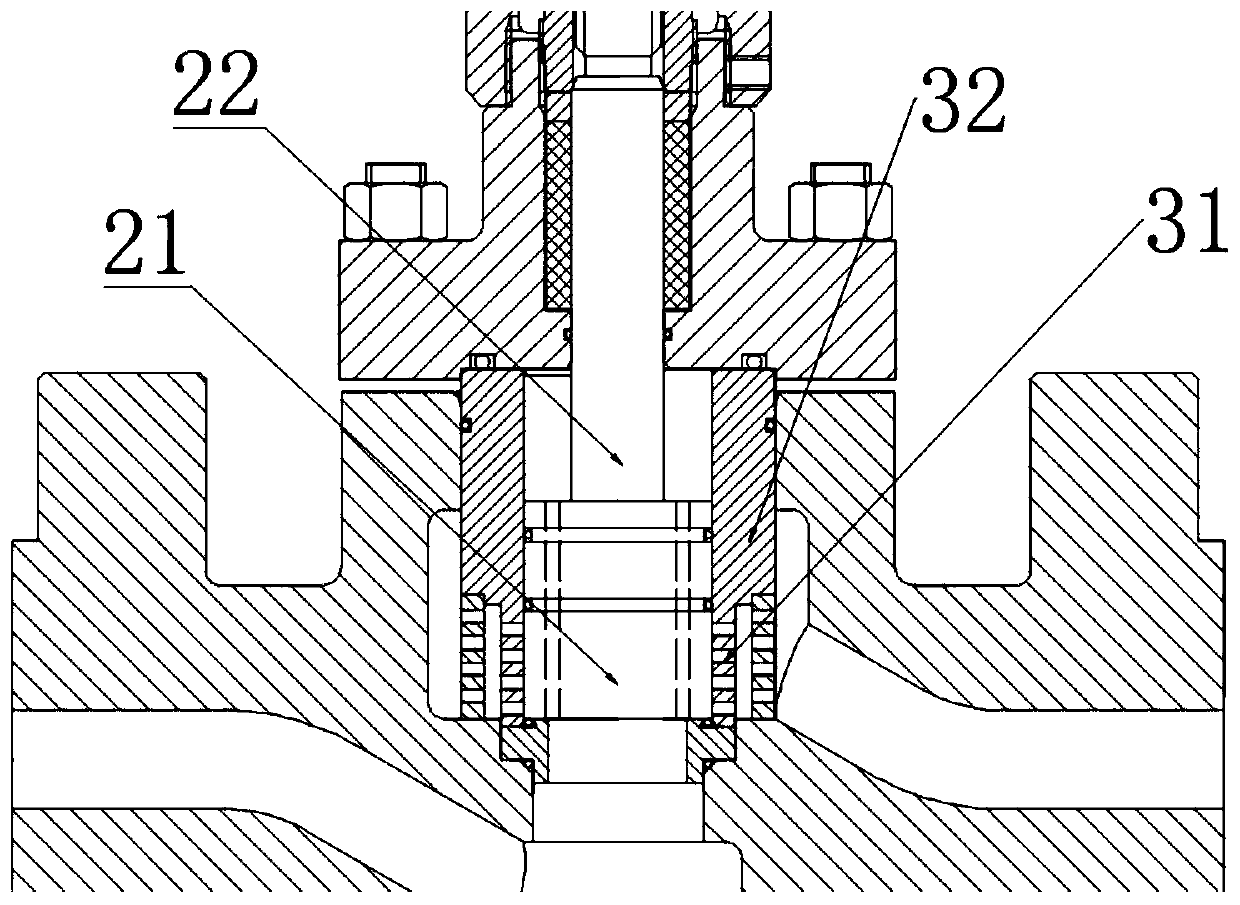

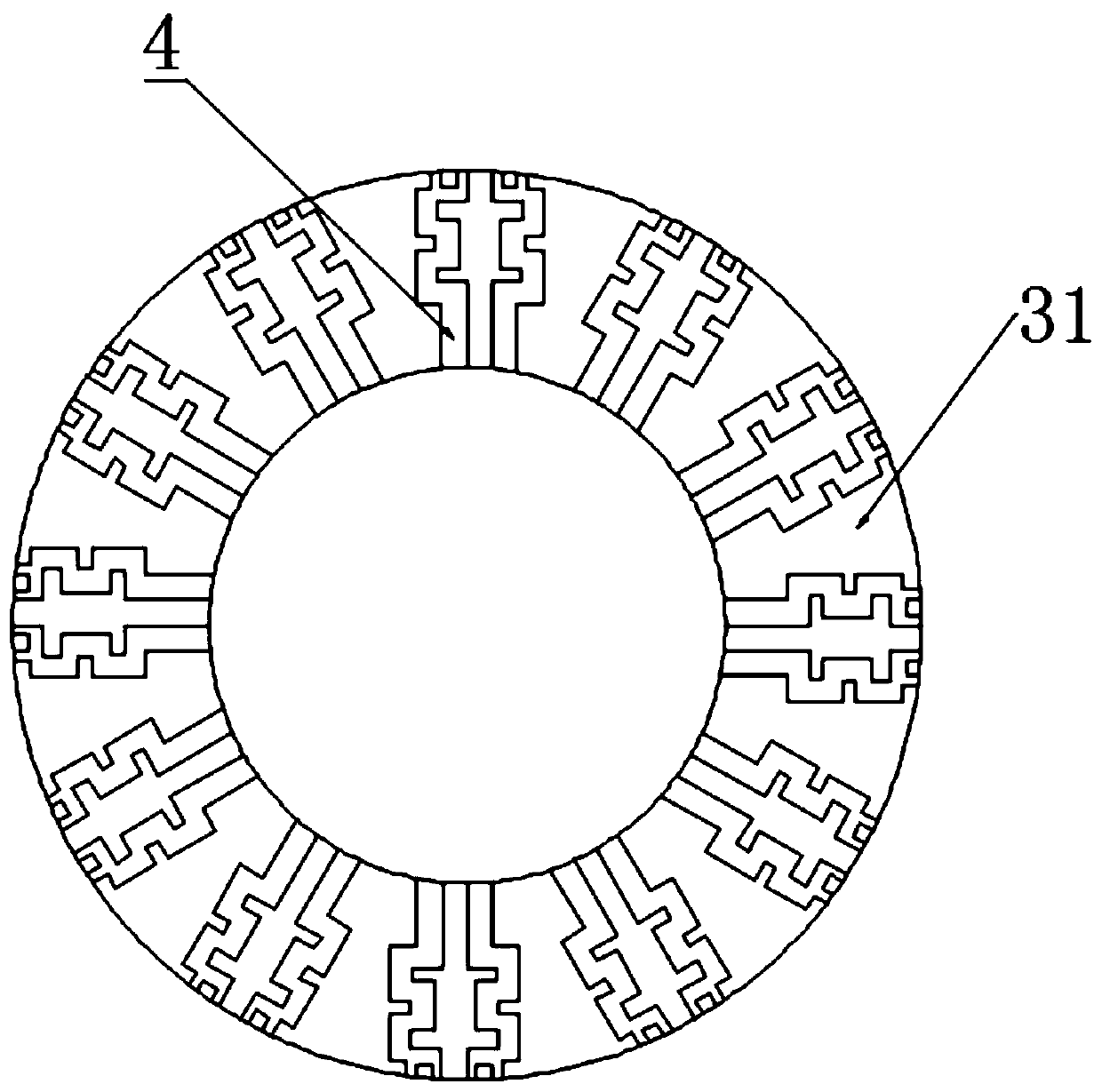

[0024] Such as Figure 1~3 As shown, the present invention is a venting shut-off valve provided with a sound-absorbing labyrinth sleeve, which is characterized in that one side of the valve body 1 is provided with a medium inlet channel 11, and the other side of the valve body 1 is provided with a medium corresponding to the medium inlet channel 11. The output channel 12, the middle part of the valve body 1 is provided with a cavity 2, the cavity 2 is provided with a valve core 21 and a pressure setting rod 22, the pressure setting rod 22 is connected with the valve core 21, and the medium inlet channel 11 is connected with the lower end surface of the cavity 2 , the medium output channel 12 is connected to the side end face of the cavity 2, the valve core 21 is matched with the connecting end face of the medium inlet channel 11 and the cavity 2 through the pressure setting rod 22, and the cavity 2 is also provided with a muffler labyrinth sleeve 3, The spool 21 and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com