Device for photo-catalytic bromination reaction

A reaction and reaction kettle technology, applied in the field of photocatalytic bromination reaction devices, can solve the problems of difficult control of the reaction liquid feed ratio, low illumination efficiency, many side reactions, etc., to improve flexibility and practicability, improve the reaction Efficiency, the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

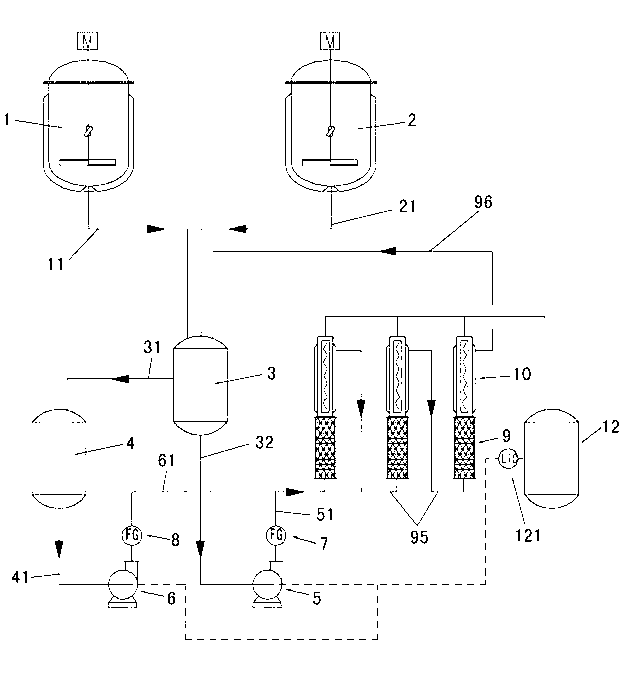

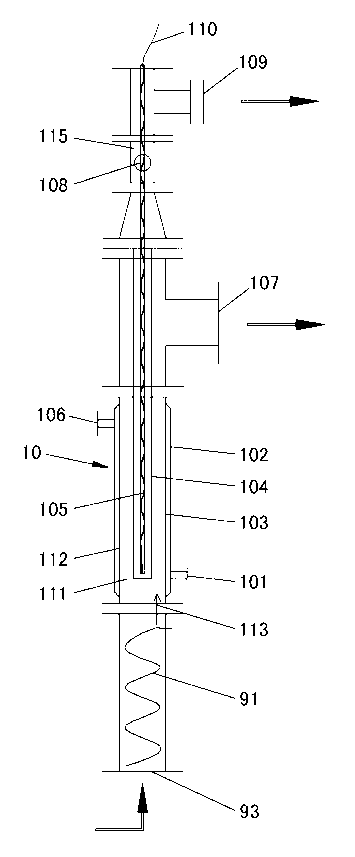

[0015] The present invention relates to a device for photocatalytic bromination reaction, such as figure 1 — figure 2 As shown, it is characterized in that it includes a first reactor 1, a second reactor 2, a front phase separation tank 3, a rear phase separation tank 4, a first circulation pump 5, a first flow meter 7, a second circulation pump 6, Second flowmeter 8, static mixer 9 and light tower 10, spiral guide plate 91 is set in the described static mixer 9, described light tower 10 comprises jacket 102, and jacket 102 wall is shaped on brine inlet 101 and brine Outlet 106, an enamelled glass interlayer container 103 is arranged in the jacket, a brine cooling chamber 112 is arranged between the jacket 102 and the enamelled glass interlayer container 103, a quartz glass tube 104 is arranged in the enamelled glass interlayer container 103, and the quartz glass tube 104 and A reaction chamber 111 is formed between the enamelled glass interlayer containers 103, and an LED l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com