Anti-deformation flame retardant solid door and preparation method thereof

A solid wood door and anti-deformation technology, which is applied in the related fields of wooden doors, can solve the problems of poor comprehensive performance of the door body, and achieve the effects of improving the comprehensive performance, increasing the strength of use, and improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

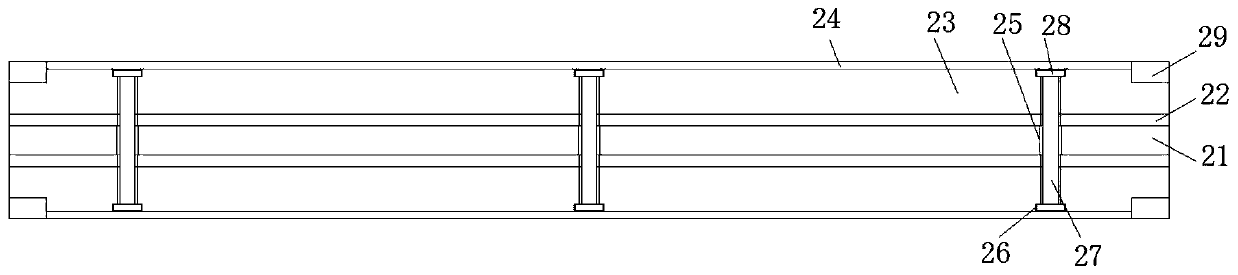

[0030] Embodiment 1: The decorative wooden board 23 is made of solid wood board, and the four corners of the outer surface of the decorative wooden board 23 are grooved respectively by using a corner cutting machine; in order to prepare for subsequent process assembly and carry out the coating process;

[0031] The coating process is used to carry out on the decorative wood board 23 to delay and reduce the loss of damage to the article;

[0032] S1: The paint used in the application needs to be independently developed. When stirring, the paint (silicate 1:3, phosphate 1:1 and silicon latex 1:2) should be stirred and mixed first. , will absorb heat and produce air-free inorganic glaze;

[0033] S2: Further, refractory materials need to be added, perchlorethylene resin 1:3 is used for secondary prevention, it releases non-flammable gas in case of fire, and it is not flammable itself, mix it with the raw materials mixed in the first step, and mix it in the subsequent operation T...

Embodiment 2

[0042] Embodiment 2: The decorative wooden board 23 is made of solid wood board, and the four corners of the outer surface of the decorative wooden board 23 are grooved respectively by using a corner cutting machine; in order to prepare for subsequent process assembly and carry out the coating process;

[0043] The coating process is used to carry out on the decorative wood board 23 to delay and reduce the loss of damage to the article;

[0044] S1: The paint used in the application needs to be independently developed. When stirring, the paint (silicate 1:2, phosphate 1:3 and silicon latex 1:1) should be stirred and mixed first. , will absorb heat and produce air-free inorganic glaze;

[0045] S2: Further, refractory materials need to be added. Perchlorethylene resin 1:4 is used for secondary prevention. It releases non-flammable gas in case of fire, and it is not flammable. Mix it with the raw materials mixed in the first step, and mix it in the subsequent operation The fina...

Embodiment 3

[0054] Embodiment 3: The decorative wooden board 23 is made of solid wood board, and the four corners of the outer surface of the decorative wooden board 23 are grooved respectively by using a corner cutting machine; in order to prepare for subsequent process assembly, and carry out the coating process;

[0055] The coating process is used to carry out on the decorative wood board 23 to delay and reduce the loss of damage to the article;

[0056] S1: The paint used in the application needs to be independently developed. When stirring, the paint silicate 1:1, phosphate 1:4 and silicon latex 1:3 are first stirred and mixed. When such raw materials encounter fire, It will absorb heat and produce an air-free inorganic glaze;

[0057] S2: Further, it is necessary to add refractory materials, perchlorethylene resin 1:1 is used for secondary prevention, it will release non-flammable gas in case of fire, and it is not flammable itself, mix it with the raw materials mixed in the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com