Method for preparing biphenyl derivative by using microchannel continuous flow reactor

A microchannel and reactor technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, preparation of organic compounds, etc., can solve the problems of runaway reaction, slow reaction or even stop, low heat transfer efficiency, etc. , to achieve the effect of reducing the reaction time, shortening the diffusion distance, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0069] Experimental Example 1 Preparation of Grignard Reagent

[0070] Preparation of Grignard Reagent for 4-Chloro-o-xylene : According to the standard operation of Grignard reagent preparation, a small amount of 4-chloro-o-xylene and solvent are added dropwise to the activated magnesium chips under nitrogen gas, and a small amount of iodine is added as an initiator and heated to initiate. After initiation, the remaining 4-chloro-o-xylene and solvent were added dropwise and kept in a reflux state, and continued to reflux for 2 hours after the dropwise addition was completed. Calibrate format reagent, adjust the concentration to 2.5mol / L. record as 1 # format reagents.

[0071] Preparation of Grignard reagent for p-chlorotoluene : According to the standard operation of the Grignard reagent preparation, a small amount of p-chlorotoluene and solvent are added dropwise to the activated magnesium chips under nitrogen conditions, and a small amount of iodine is added as an in...

Embodiment 1

[0074] Example 1 Preparation of 3,3',4,4'-tetramethylbiphenyl

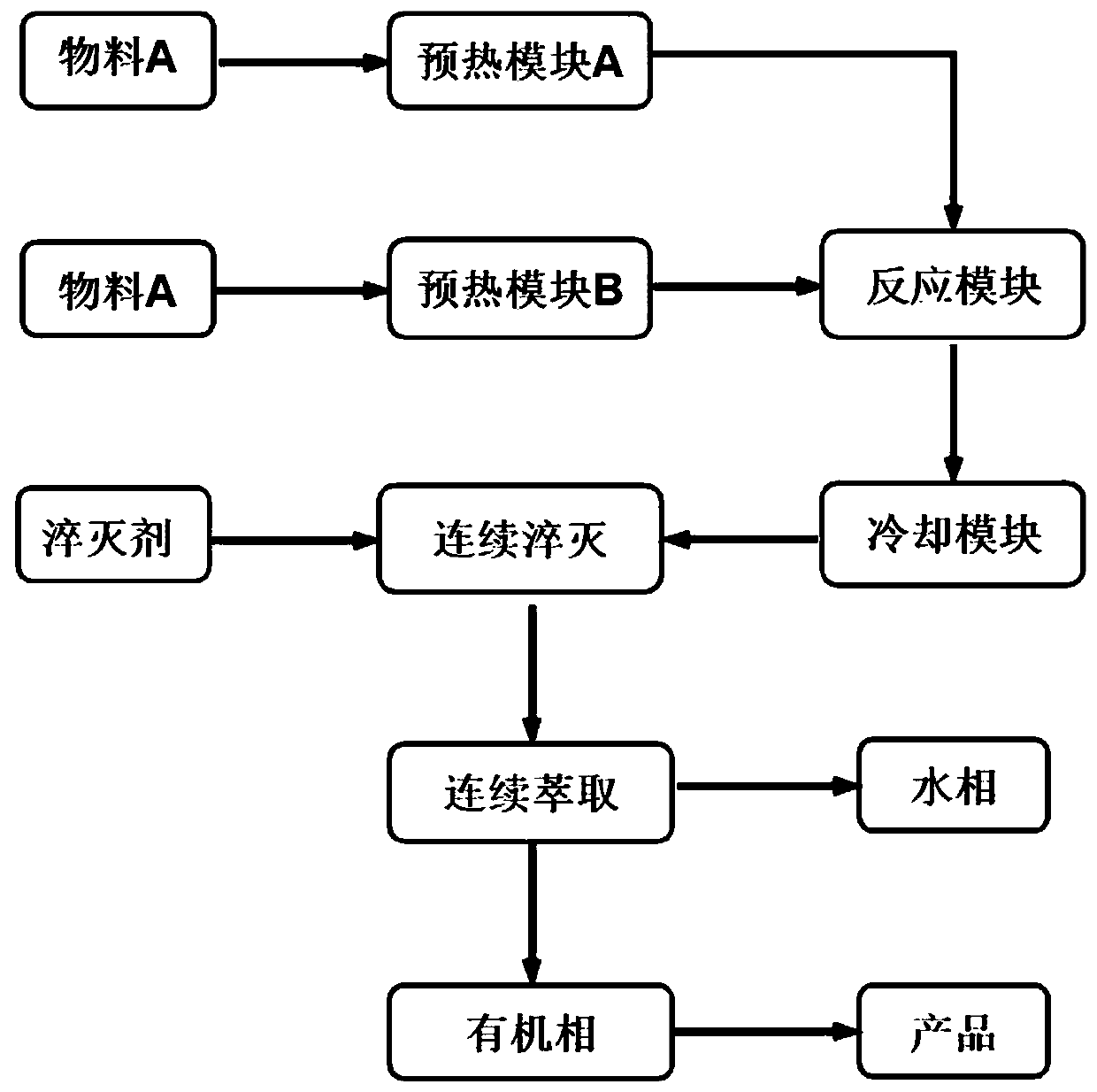

[0075] Typically, with figure 1 The process schematic diagram shown in is a route to prepare biphenyl compounds. The continuous flow reactor is a microchannel continuous flow reactor (Corning SiC-G1), and the internal structure of the microchannel continuous flow reactor is a heart-shaped channel. The diameter of the microchannel is 100 μm.

[0076] Preparation method 1

[0077] Take 10mol of calibrated 1 # The THF solution of Grignard reagent is used as material A solution, take 10mol of 4-chloro-o-xylene, 30mmol of NiCl 2 , PPh of 60mmol 3 Mix and heat to 80°C, and heat for 30 minutes, as material B solution;

[0078] Then through the metering pump, A and B are respectively entered into the preheating module of the continuous flow reactor according to the molar ratio of 1:1, and the temperature of the preheating module is controlled to 120°C;

[0079]After passing through the preheating module, solution...

Embodiment 2

[0083] Example 2 Preparation of 4,4'-dimethylbiphenyl

[0084] The preparation process is as figure 1 The process shown in Fig.

[0085] Take 10mol of calibrated 2 # The THF solution of Grignard reagent is used as material A solution, take 10mol of p-chlorotoluene, 20mmol of NiCl 2 , 40mmol of PPh 3 Mix and heat to 80°C, and heat for 30 minutes, as material B solution;

[0086] Then through the metering pump, A and B are respectively entered into the continuous flow reactor preheating module according to the molar ratio of 1:1, and the temperature of the preheating module is controlled to 140 °C; the continuous flow reactor is a microchannel continuous flow reactor (Corning SiC-G1) , the internal structure of the microchannel continuous flow reactor is a heart-shaped channel;

[0087] After passing through the preheating module, solutions A and B enter the mixed reaction module, the reaction temperature is set at 140°C (the first 80% module) + 175°C (the last 20% module),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com