Dry, comfortable and breathable paper diaper and manufacturing technique thereof

A diaper and dry technology, which is applied in the field of diapers, can solve the problems of poor integrity of wood pulp and polymer water-absorbing resin, difficulty in improving the water-absorbing core layer, and poor air permeability of baby diapers, so as to improve the liquid absorption effect and dryness , easier to fix the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

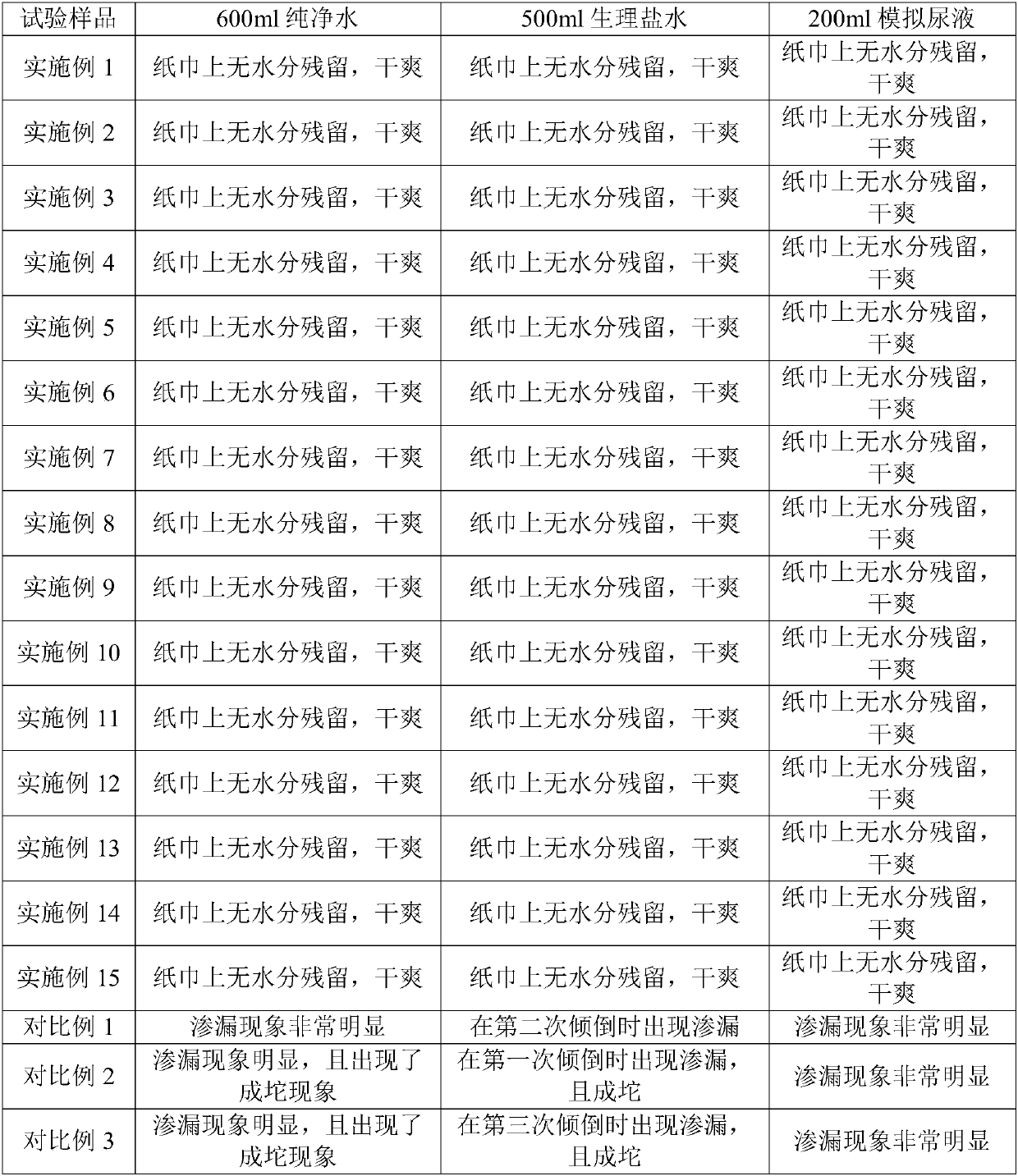

Embodiment 1

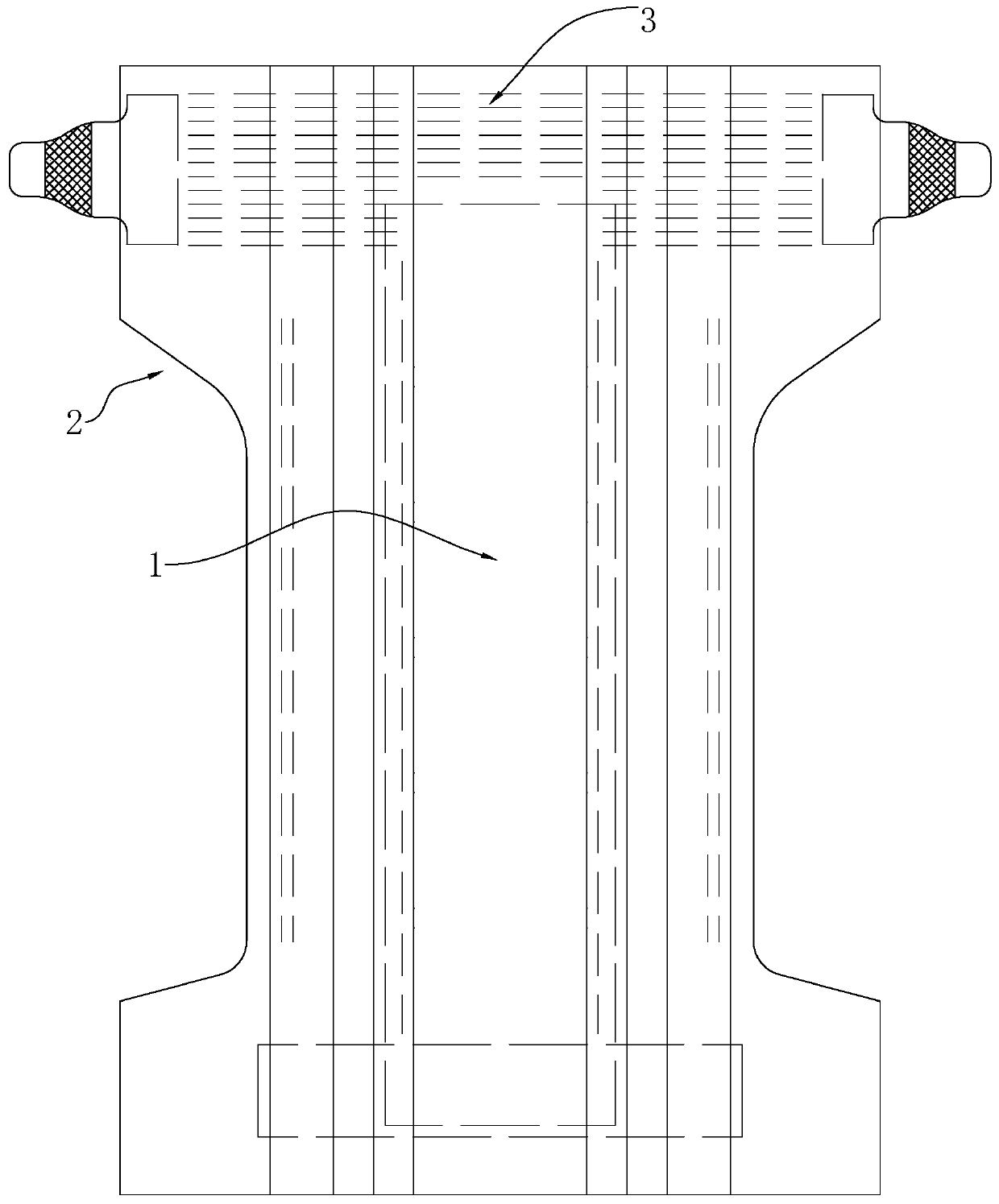

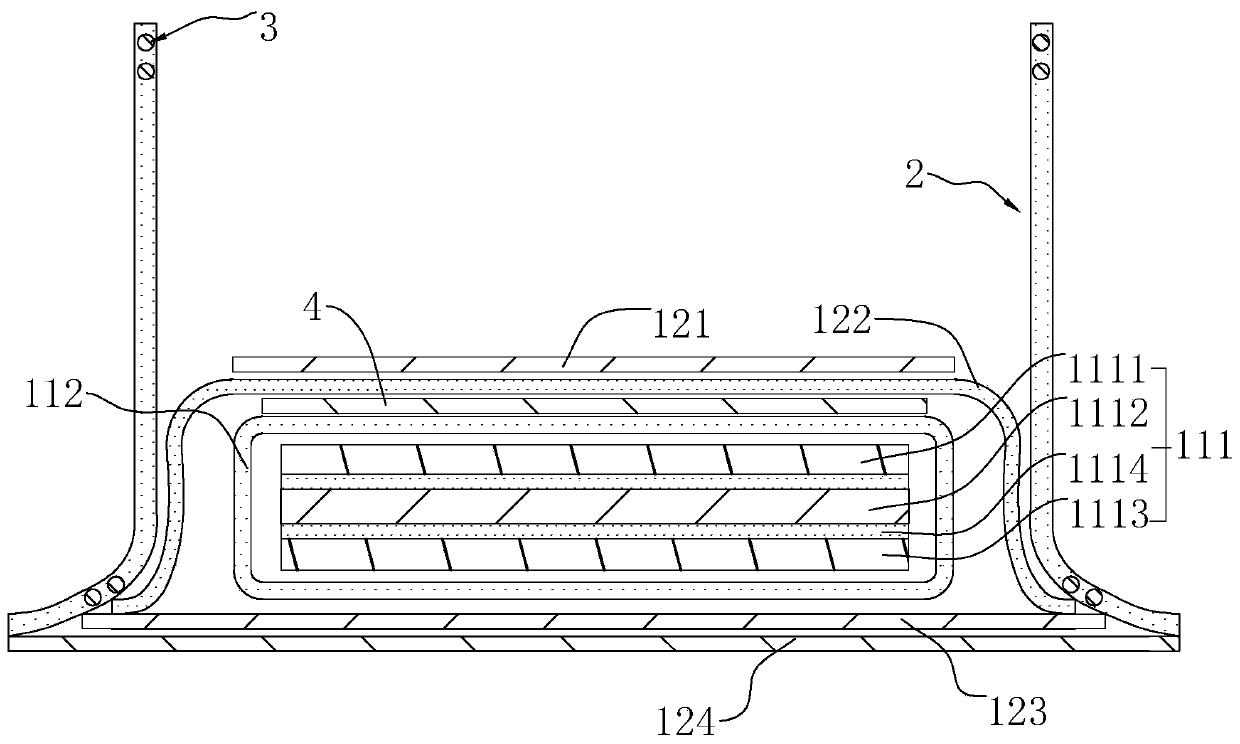

[0064] Embodiment 1: a kind of dry and comfortable, breathable paper diapers, such as figure 1 with figure 2 As shown, it includes a diaper body, a three-dimensional enclosure structure 2 arranged on the diaper body, an elastic structure 3 arranged on the diaper body and the three-dimensional enclosure structure 2; the diaper body includes a composite core layer 11 and a composite core layer 11 External cladding structure. Wherein, the composite core layer 11 includes a core inner layer 111 and a core wrapping non-woven fabric 112 wrapped outside the core inner layer 111 .

[0065] The core inner layer 111 includes a core upper layer breathable cloth 1111, a middle layer fluffy fiber net 1112, a core lower layer breathable cloth 1113, between the upper layer non-woven fabric and the middle layer fluffy fiber net 1112, the middle layer fluffy fiber net 1112 and the core lower layer breathable cloth 1113 An acrylic type superabsorbent resin layer is arranged between them. Ac...

Embodiment 2

[0076] Embodiment 2: A dry and breathable paper diaper, the difference from Embodiment 1 is that in step 1, the pretreatment of ES fibers: the concentration is 5% sericin aqueous solution is sprayed on the long-fiber ES fibers, Drying at a temperature of 30° C. in a sterile environment, and then cutting the ES fibers into short fibers with a length of 50-80 mm, wherein the weight ratio of the sericin aqueous solution to the long-fiber ES fibers is 1:2. Then the long fibers are cut into short fibers, and the middle layer fluffy fiber web 1112 with a thickness of 0.1 mm is prepared by hot air method.

Embodiment 3

[0077] Example 3: A dry and breathable paper diaper, the difference from Example 1 is that in step 1, during the pretreatment of ES fibers, the concentration of sericin aqueous solution is 6%, and the drying temperature is 33°C. And the weight ratio of the sericin aqueous solution to the long-fiber ES fiber is 1:3. The thickness of the middle fluffy web 1112 is 0.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com