Freeze-dried tofu and preparation method thereof

A technology for freeze-drying tofu and tofu, which is applied in the food field, can solve the problems of no delicate tofu, discount in nutritional value, damage to appearance and structure, etc., and achieve the effects of color retention, convenience in eating, and production time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

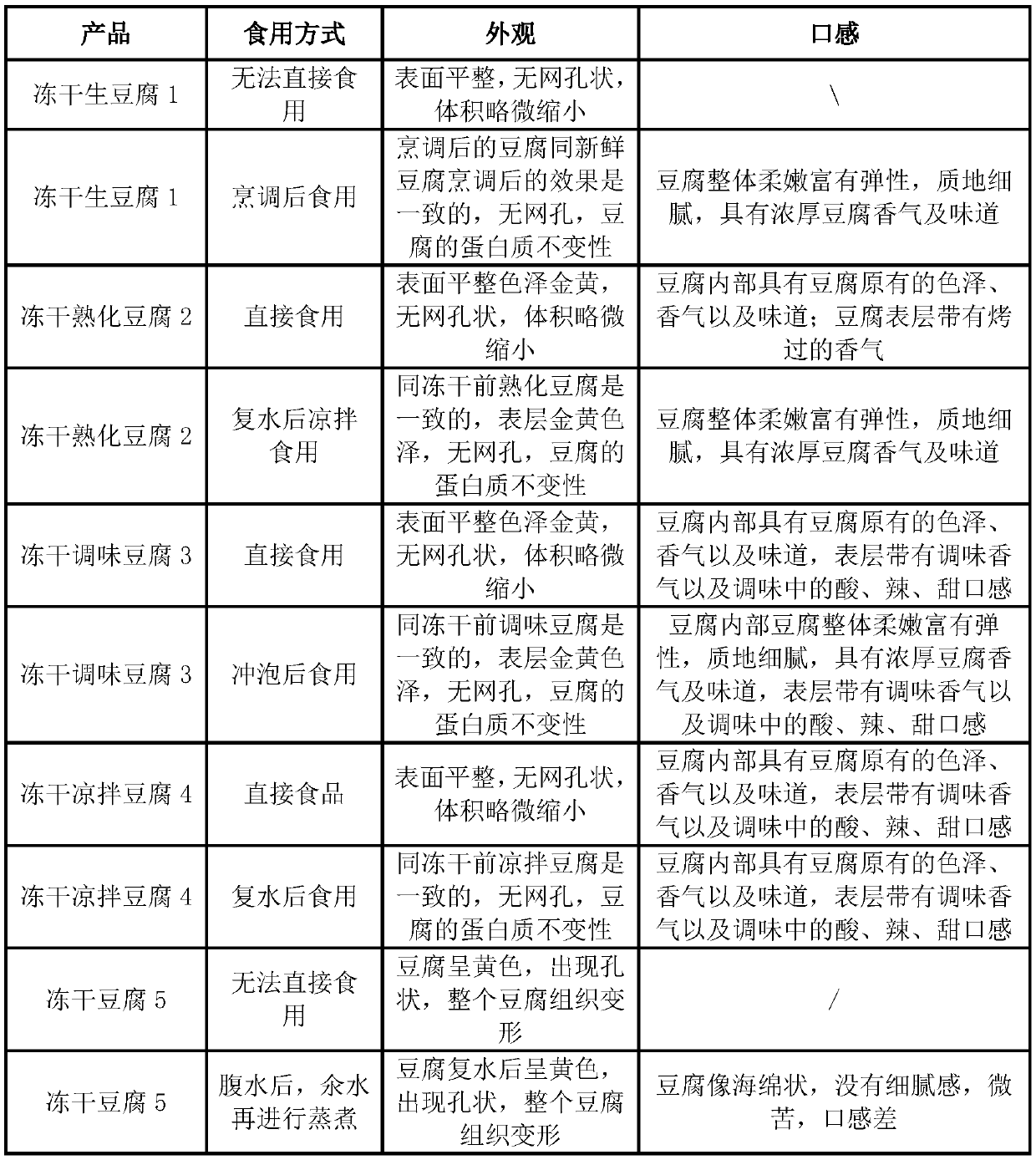

Examples

Embodiment 1

[0059] A preparation method of freeze-dried tofu, comprising the steps of:

[0060] S002: after cleaning the tofu of 500g, set aside;

[0061] S006: Vacuum freeze-drying tofu to obtain freeze-dried raw tofu 1.

[0062] The tofu prepared by SOO2 is pushed into the vacuum freeze-drying system, and the first stage of SOO6 is pre-cooled. Control the temperature of the cold trap of the vacuum freeze-drying system at -25~-30°C, vacuumize at the same time, the pre-cooling time is 50 minutes, and freeze the tofu skin to a thickness of 1mm. At this time, the temperature of the tofu center is controlled at 0°C. Then enter the second stage of SOO6, drying, which is to control the vacuum degree of the vacuum freeze-drying system at 70-100Pa, the heating temperature is 52-60°C, and the dehydration time is 22 hours. Freeze-dried raw tofu 1 is obtained after sublimation and dehydration. Freeze-dried raw tofu 1 has a water content of 3%, is rehydrated, and freeze-dried raw tofu 1 is 475g af...

Embodiment 2

[0064] A preparation method of freeze-dried tofu, comprising the steps of:

[0065] S002: Wash 500g tofu for subsequent use;

[0066] S003: Cut the reserved tofu into slices for later use;

[0067] S004: Wait for the tofu ripening treatment, roast the sliced tofu;

[0068] S006: Vacuum freeze-drying roasted tofu to obtain freeze-dried cooked tofu 2.

[0069] The baked tofu in the above S004 is pushed into the vacuum freeze-drying system, and the first stage of SOO6 is carried out to pre-cool. Control the temperature of the cold trap of the vacuum freeze-drying system at -25~-30°C, vacuumize at the same time, the pre-cooling time is 55 minutes, freeze the tofu skin to a thickness of 1mm, at this time, the temperature of the center of the tofu is controlled at 3°C. Then enter the second stage of SOO6, drying, which is to control the vacuum degree of the vacuum freeze-drying system at 70-100Pa, the heating temperature is 52-60°C, and the dehydration time is 19 hours. After s...

Embodiment 3

[0071] A preparation method of freeze-dried tofu, comprising the steps of:

[0072] S002: Wash 500g tofu for subsequent use;

[0073] S003: Cut the reserved tofu into slices for later use;

[0074] S004: Wait for the tofu ripening treatment, roast the sliced tofu;

[0075] S005: marinate the baked tofu for seasoning;

[0076] S006: Vacuum freeze-dry seasoned tofu to prepare freeze-dried seasoned tofu 3.

[0077] The seasoned tofu in the above-mentioned S005 is pushed into the vacuum freeze-drying system, and the first stage of SOO6 is carried out to pre-cool. Control the temperature of the cold trap of the vacuum freeze-drying system at -25~-30°C, vacuumize at the same time, the pre-cooling time is 70 minutes, and freeze the tofu skin to a thickness of 5mm. At this time, the temperature of the tofu center is controlled at 1°C. Then enter the second stage of SOO6, drying, which is to control the vacuum degree of the vacuum freeze-drying system at 70-100Pa, the heating tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com