A fiber optic acoustic emission vibration sensor and partial discharge sensing system

A partial discharge and sensing system technology, applied in the field of optical fibers, can solve the problems of poor anti-interference, inability to be practical in large quantities, easily affected by the monitoring environment, etc., and achieve the effects of enhanced sensing sensitivity and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

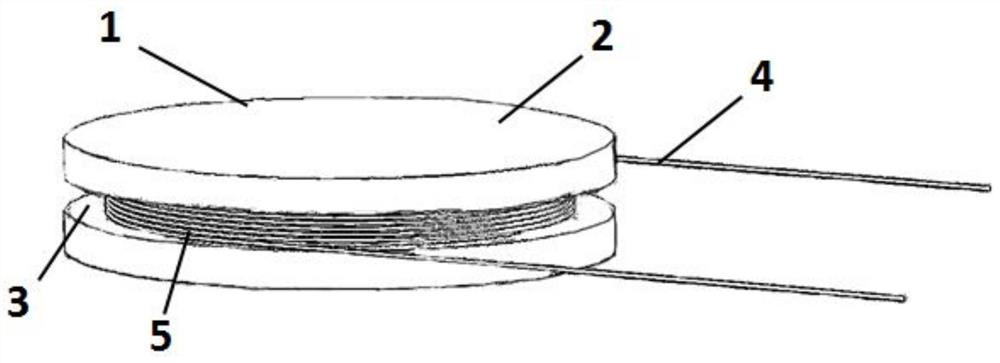

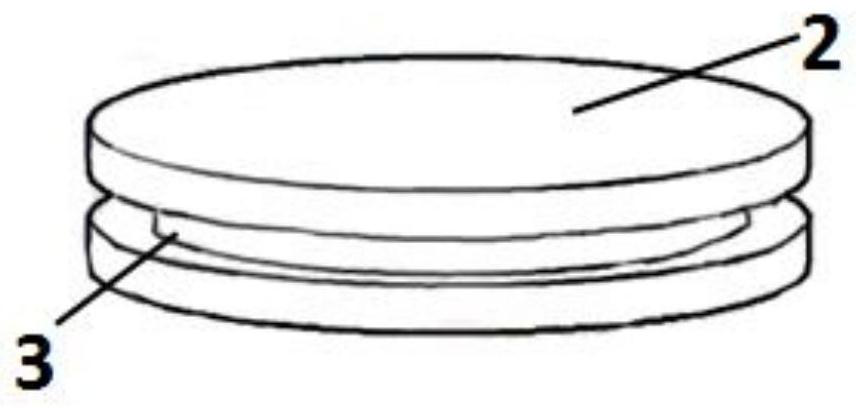

[0020] Such as figure 1 Shown, the present invention is a kind of optical fiber acoustic emission vibration sensor 1, comprises figure 2 In the cylindrical sensor head 2, the side wall of the sensor head 2 is provided with an annular groove 3 along its circumference, and the annular groove 3 is wound with a multi-turn sensing optical fiber 4, and the multi-turn sensing optical fiber 4 is covered with silicon Rubber 5 and silicone rubber 5 are covered on the sensing optical fiber 4 after natural curing of liquid silicone rubber. The Poisson's ratio of the silicone rubber 5 material is 0.49, and the expansion of its lateral dimension will also increase accordingly. The sensing fiber 4 will also ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com