A sro-doped sno 2 base nh 3 Sensitive material preparation method

A technology of sensitive materials and sensitive components, which is applied in the direction of material resistance, material analysis, and material analysis through electromagnetic means, can solve the problems of unclear influence on gas-sensing performance, and achieve improved gas-sensing performance, high yield, and increased active site effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] SrO doped SnO 2 Preparation of NH from sensitive materials 3 sensor

[0038]Dissolve 1g of cetyltrimethylammonium bromide in 100ml of 8mol / L nitric acid solution, stir evenly, add 5g of tin particles, stir in a water bath at 75°C to make the tin particles react completely, then put After the generated precipitate was separated, washed and dried, it was sintered at 500 °C for 3 hours to obtain SnO 2 nanoparticles. 0.3g of SrCO 3 Dissolve in 20ml of dilute hydrochloric acid, stir well and add 1g of SnO 2 nanoparticles. Under the hydrothermal condition of 90 °C, the magnetic stirring was continued, and the solution was evaporated to dryness to obtain strontium-loaded SnO 2 nanoparticles, and then heat-treated at 450 °C for 2 h to obtain SrO-supported SnO 2 sensitive material. Mix the sensitive material with deionized water and alcohol at a mass ratio of 1:0.5:0.5, and evenly coat the surface of the ceramic tube. After drying, weld the working electrode and the heat...

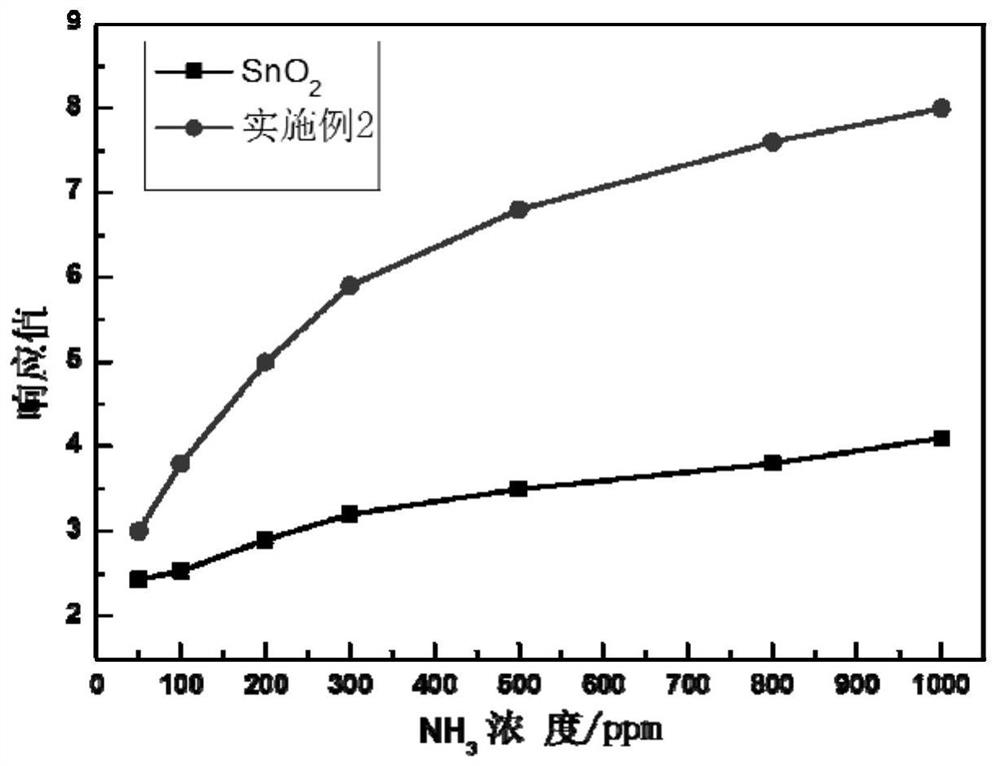

Embodiment 2

[0040] SrO doped SnO 2 Preparation of NH from sensitive materials 3 sensor

[0041] Dissolve 2g of cetyltrimethylammonium bromide in 100ml of 8mol / L nitric acid solution, stir evenly, add 5g of tin particles, stir in a water bath at 75°C to make the tin particles react completely, then put After the generated precipitate was separated, washed and dried, it was sintered at 500 °C for 3 hours to obtain SnO 2 nanoparticles. 0.3g of SrCO 3 Dissolve in 20ml of dilute hydrochloric acid, stir well and add 1g of SnO 2 nanoparticles. Under the hydrothermal condition of 90 °C, the magnetic stirring was continued, and the solution was evaporated to dryness to obtain strontium-loaded SnO 2 nanoparticles, and then heat-treated at 450 °C for 2 h to obtain SrO-supported SnO 2 sensitive material. Mix the sensitive material with deionized water and alcohol at a mass ratio of 1:0.5:0.5, and evenly coat the surface of the ceramic tube. After drying, weld the working electrode and the hea...

Embodiment 3

[0045] SrO doped SnO 2 Preparation of NH from sensitive materials 3 sensor

[0046] Dissolve 3g of cetyltrimethylammonium bromide in 100ml of 8mol / L nitric acid solution, stir evenly, add 5g of tin particles, stir in a water bath at 75°C to make the tin particles react completely, then put After the generated precipitate was separated, washed and dried, it was sintered at 500 °C for 3 hours to obtain SnO 2 nanoparticles. 0.3g of SrCO 3 Dissolve in 20ml of dilute hydrochloric acid, stir well and add 1g of SnO 2 nanoparticles. Under the hydrothermal condition of 90 °C, the magnetic stirring was continued, and the solution was evaporated to dryness to obtain strontium-loaded SnO 2 nanoparticles, and then heat-treated at 450 °C for 2 h to obtain SrO-supported SnO 2 sensitive material. Mix the sensitive material with deionized water and alcohol at a mass ratio of 1:0.5:0.5, and evenly coat the surface of the ceramic tube. After drying, weld the working electrode and the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com