Vertical lifting stereo garage

A three-dimensional garage and vertical lifting technology, which is applied in the direction of buildings, building types, and buildings where cars are parked, can solve the problems of high management costs, waste of parking time for car owners, and long time to find a car, and achieve high sensitivity and positioning accuracy. The effect of improving space utilization and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

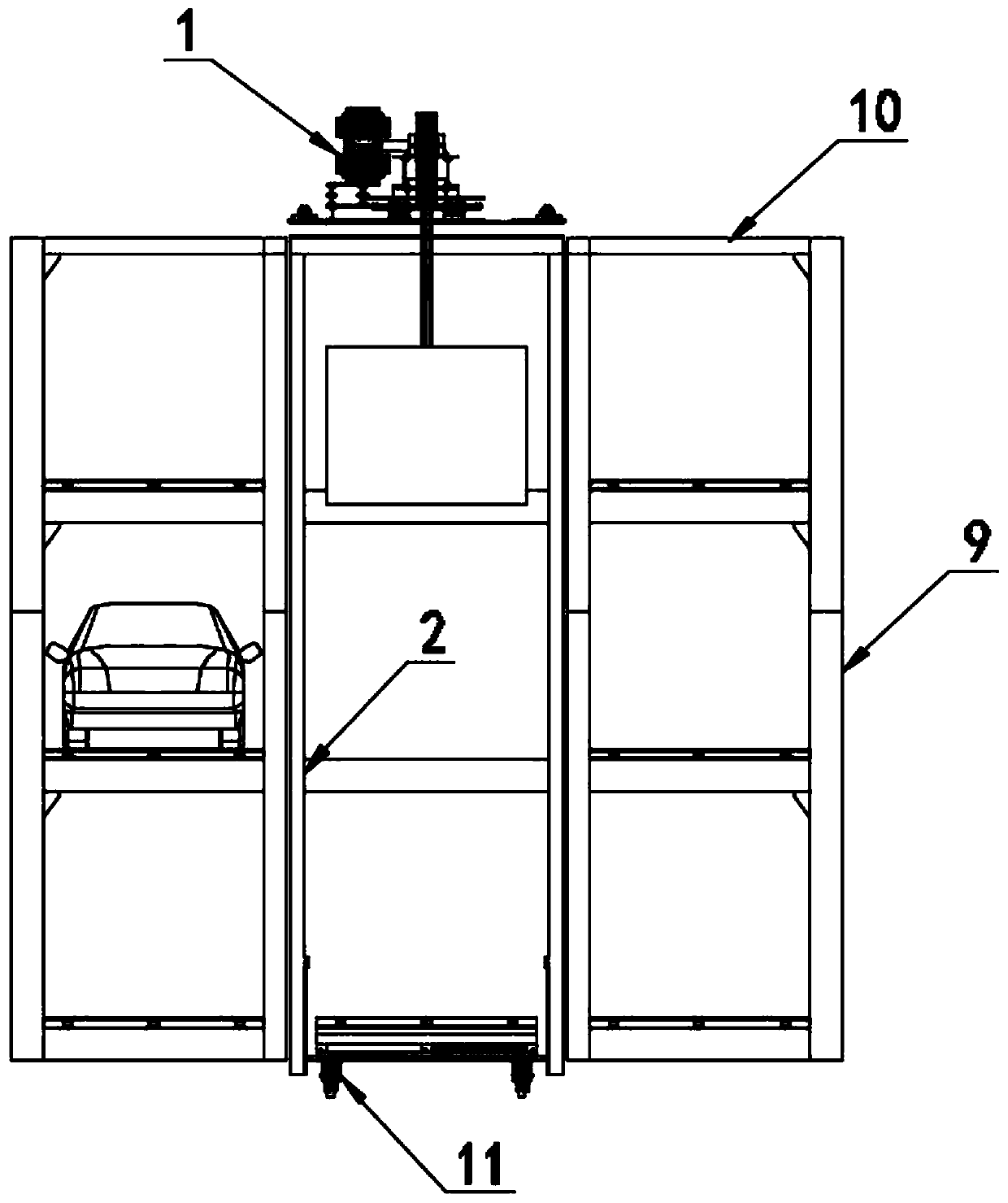

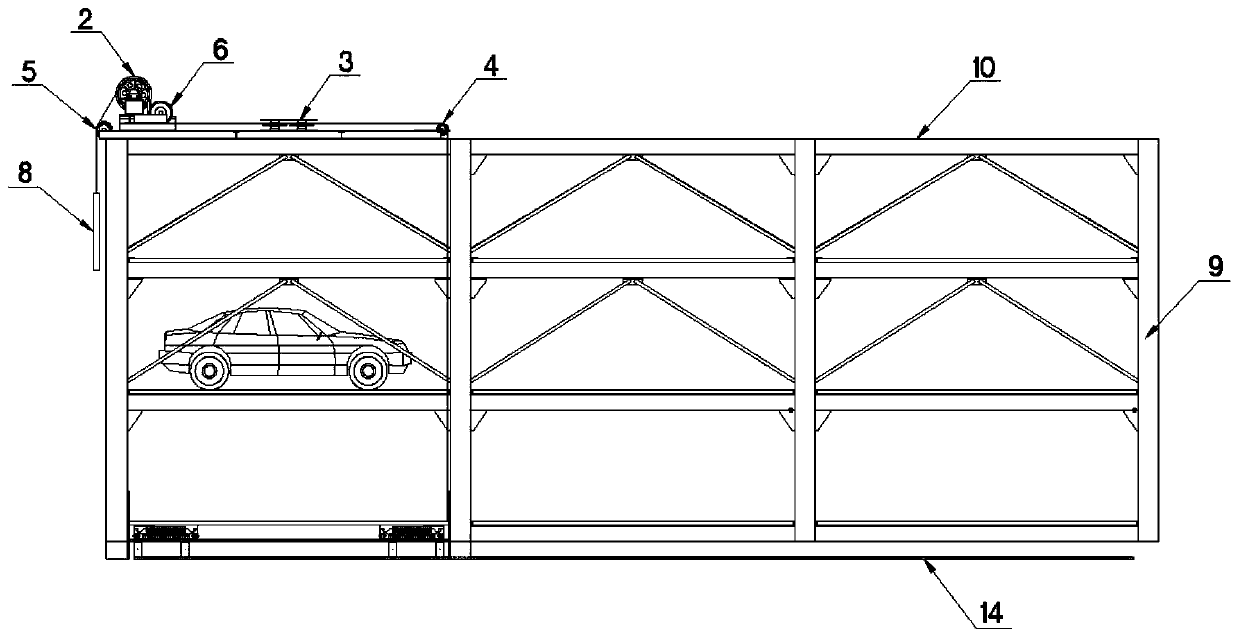

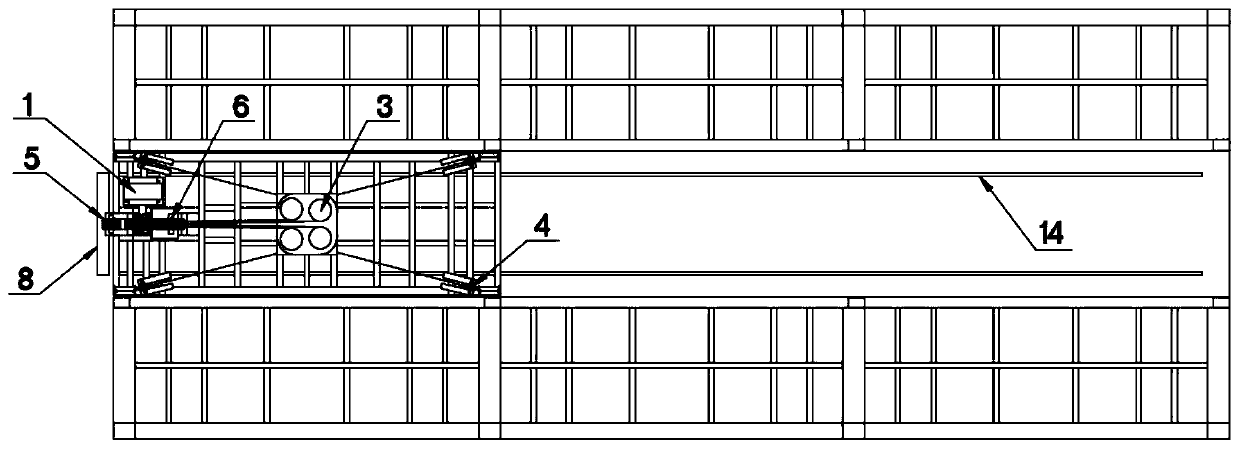

[0029] Such as Figure 1 to Figure 6 A kind of vertical lifting three-dimensional garage shown, comprises garage main body, mobile bracket 16, rail 14, lifting mechanism, longitudinal movement mechanism and lateral movement mechanism 12; And hub motor 11, described hub motor 11 uses motor support 1109 to be fixedly installed on the bottom of mobile support 16, provides power for the movement of mobile support 16 through hub motor 11; Fixed shaft 1109-1 is arranged between described motor support 1109 , the hub motor 11 is sleeved on the fixed shaft 1109-1; the hub motor 11 includes a rotor housing 1101, a first end cover 1102-1, a second end cover 1102-2, a stator bracket 1104, a stator end Cover 1105, motor stator 1106, in-wheel motor spindle 1107, stator winding 1103, permanent magnet 1110 and special bearing 1108; the first end cover 1102-1 and the second end cover 1102-2 are both disc-shaped structures, And a boss is provided at the center of the outer side of the disc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com