Composite plate and preparation method thereof

A composite board and composite board technology, which is applied in the field of building decoration materials, can solve the problems that rock slabs are easy to cause edge collapse, rock slabs are easy to break, and boards are fragile, and it is beneficial to mass production, the production process is simple, and the overall strength is enhanced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

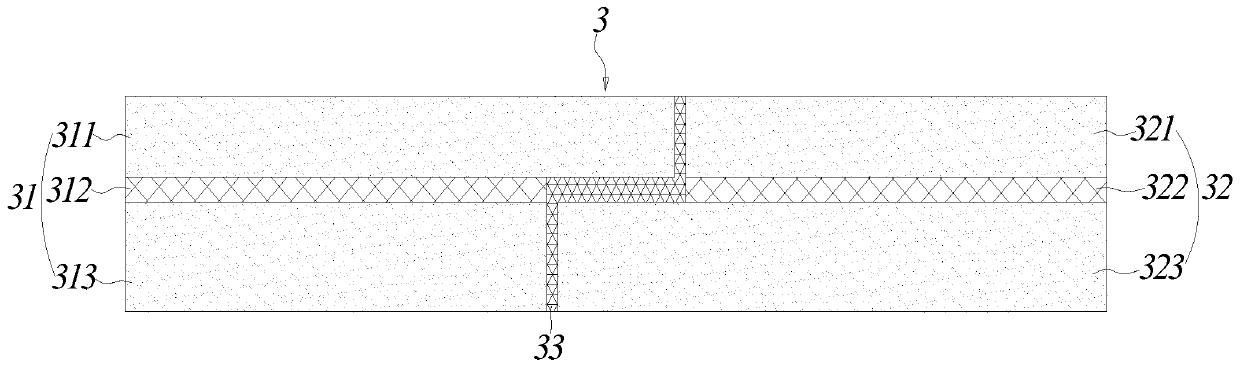

[0039] Figure 1~5 A composite board according to an embodiment of the present invention is schematically shown.

[0040] Such as Figure 1~5 As shown, according to one aspect of the present invention, a composite board 3 is provided, and the composite board 3 includes a first composite board 31 and a second composite board 32. The first composite board 31 and the second composite board 32 are overlapped to form a whole composite board 3.

[0041] The first composite board 31 includes a first rock board 311, a second rock board 313 and a first adhesive 312. The first rock board 311 and the second rock board 313 are fixedly connected by the first adhesive 312.

[0042] The second composite board 32 includes a third rock board 321, a fourth rock board 323 and a second adhesive 322, and the third rock board 321 and the fourth rock board 323 are fixedly connected by the second adhesive 322.

[0043] Both the first adhesive 312 and the second adhesive 322 are acrylic artificial stone ad...

Embodiment 2

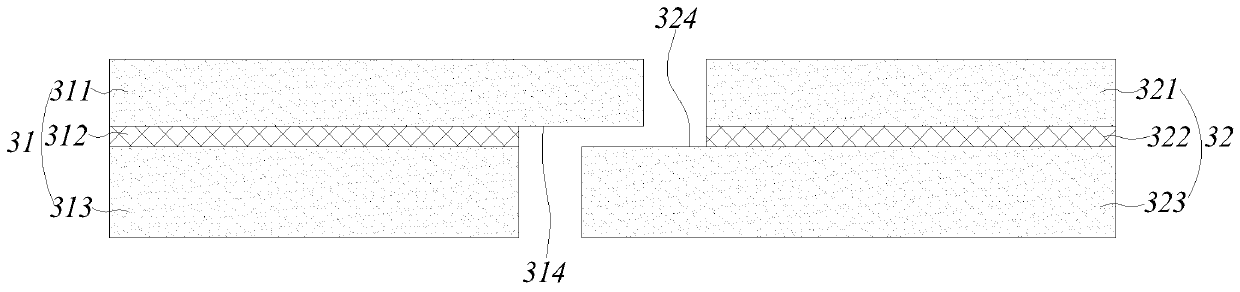

[0067] The structure of the composite sheet 3 in this embodiment is basically the same as that of the composite sheet 3 in Example 1, and the difference lies in:

[0068] (1) In this embodiment, the thickness of the first rock board 311 is 6 mm, the thickness of the second rock board 313 is 3 mm, the thickness of the third rock board 321 is 6 mm, and the thickness of the fourth rock board 323 is 3 mm. The coating thickness of the first adhesive 312 and the second adhesive 322 is approximately 1 mm.

[0069] (2) such as Figure 4 As shown, in the preparation process of the composite sheet 33 of this embodiment, the preparation sequence of the first composite board 31 and the second composite board 32 is exchanged. details as follows:

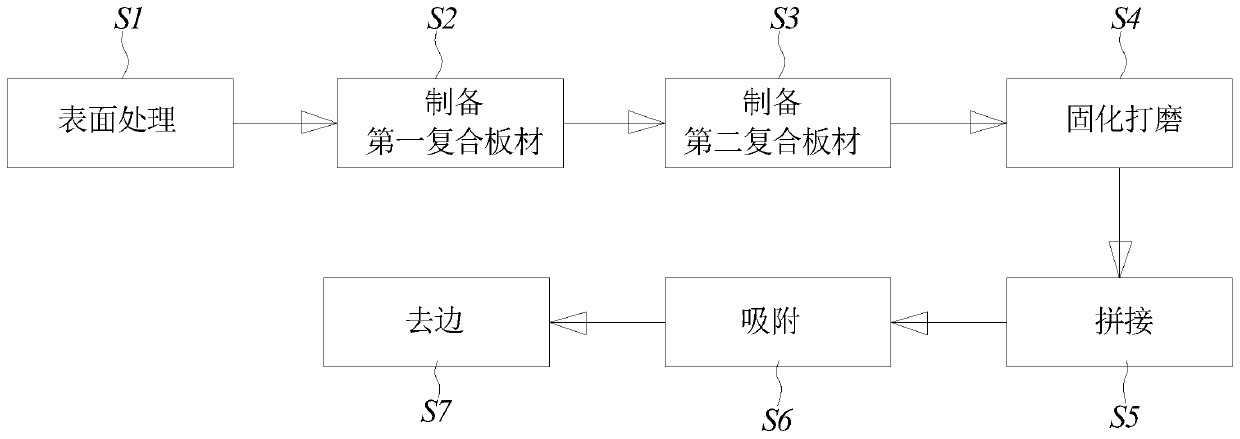

[0070] The preparation of the composite board 33 of this embodiment includes the following steps:

[0071] S1. Surface treatment: clean the bonding surfaces of the first rock board 311, the second rock board 313, the third rock board 321, and the fourth...

Embodiment 3

[0079] The structure of the composite sheet 3 in this embodiment is basically the same as that of the composite sheet 3 in Example 1, and the difference lies in:

[0080] In this embodiment, the thickness of the first rock board 311 is 6 mm, the thickness of the second rock board 313 is 6 mm, the thickness of the third rock board 321 is 6 mm, and the thickness of the fourth rock board 323 is 6 mm. The coating thickness of the first adhesive 312 and the second adhesive 322 is approximately 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com