A kind of hydroxyl polyester resin prepared based on Tgic by-product and preparation method

A technology of hydroxy polyester resin and by-products, applied in the field of hydroxy polyester resin, can solve the problems of low-end products and insufficient added value, and achieve the effects of excellent water resistance, enhanced fluidity, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

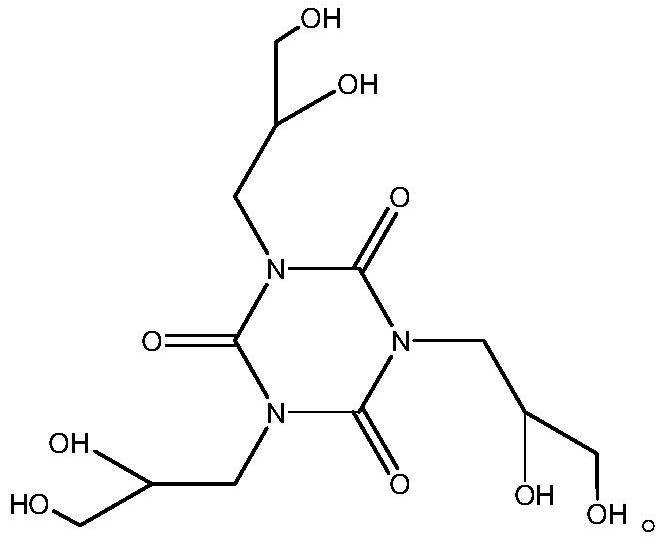

Method used

Image

Examples

Embodiment 1

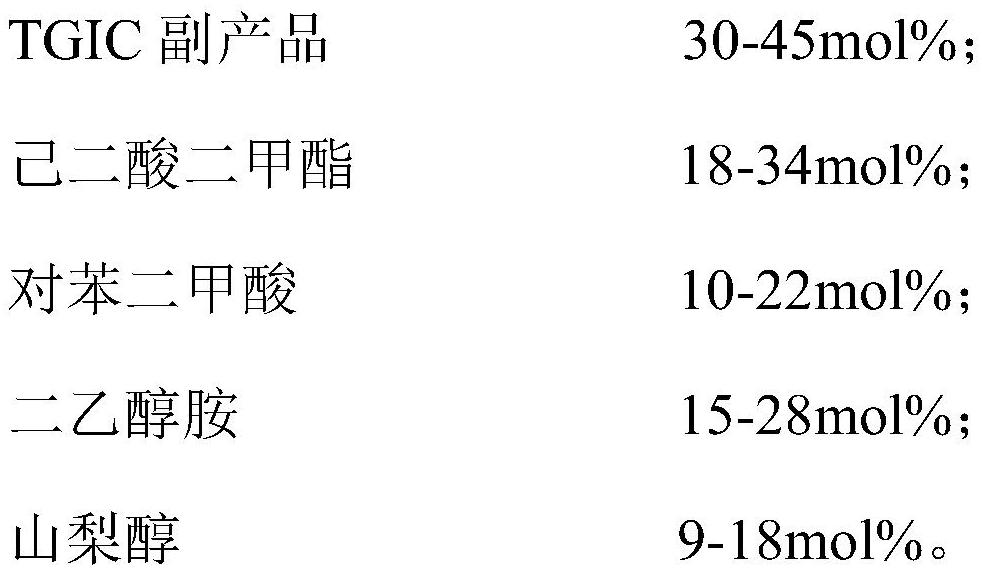

[0029] The hydroxyl polyester resin prepared based on the TGIC by-product described in this embodiment includes the raw material monomers of the following molar content in terms of the total amount of raw materials for its preparation:

[0030]

[0031] The preparation method of hydroxyl polyester resin described in the present embodiment, comprises the steps:

[0032] (1) Add the TGIC by-product and dimethyl adipate in the above formula into the reactor, slowly raise the temperature of the reactor, and gradually raise the temperature from 60°C to 100°C at a heating rate of 20°C / h and keep it warm for reaction 2h, then start the vacuum to carry out the decompression reaction for 1-3h, and stop the reaction when the viscosity of the reaction system reaches 500-700mPa·s / 180°C;

[0033] (2) Then add the terephthalic acid and diethanolamine in the formula amount to the above-mentioned mixed material, under the protection of nitrogen, gradually raise the temperature to 200°C at ...

Embodiment 2

[0038] The hydroxyl polyester resin prepared based on the TGIC by-product described in this embodiment includes the raw material monomers of the following molar content in terms of the total amount of raw materials for its preparation:

[0039]

[0040] The preparation method of hydroxyl polyester resin described in the present embodiment, comprises the steps:

[0041](1) Add the TGIC by-products and dimethyl adipate in the above formula into the reactor, slowly raise the temperature of the reactor, and gradually raise the temperature from 60°C to 120°C at a rate of 20°C / h and keep it warm for reaction 2h, then start the vacuum to carry out the decompression reaction for 1-3h, and stop the reaction when the viscosity of the reaction system reaches 500-700mPa·s / 180°C;

[0042] (2) Then add the terephthalic acid and diethanolamine in the formula amount to the above-mentioned mixed material, under the protection of nitrogen, gradually raise the temperature to 220°C at a heatin...

Embodiment 3

[0047] The hydroxyl polyester resin prepared based on the TGIC by-product described in this embodiment includes the raw material monomers of the following molar content in terms of the total amount of raw materials for its preparation:

[0048]

[0049] The preparation method of hydroxyl polyester resin described in the present embodiment, comprises the steps:

[0050] (1) Add the TGIC by-products and dimethyl adipate in the above formula into the reactor, raise the temperature of the reactor slowly, and gradually raise the temperature from 60°C to 110°C at a rate of 20°C / h and keep it warm for reaction 2h, then start the vacuum to carry out the decompression reaction for 1-3h, and stop the reaction when the viscosity of the reaction system reaches 500-700mPa·s / 180°C;

[0051] (2) Then add the terephthalic acid and diethanolamine in the formula amount to the above mixed material, under the protection of nitrogen, gradually raise the temperature to 210°C at a heating rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com