A kind of detoxification method of chromium polluted soil

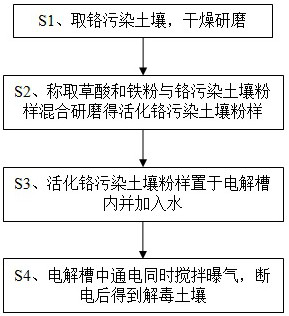

A technology for chromium-contaminated soil and an electrolytic cell is applied in the field of remediation of contaminated soil, which can solve the problems of low detoxification efficiency and achieve the effects of high-efficiency detoxification, improved migration activity, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The effect of oxalic acid and chromium-contaminated soil powder mass percentage on the reduction efficiency of hexavalent chromium:

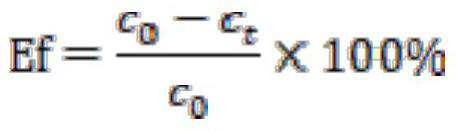

[0029] Weigh the chromium-contaminated soil, grind it after drying, and pass through a 100-mesh sieve to obtain a chromium-contaminated soil powder sample. Weigh oxalic acid according to the mass percentage of oxalic acid and chromium-contaminated soil powder sample at 3.2%, 3.5%, 3.8%, 4%, 6%, 8%, 8.2%, and 8.5%, and weigh 3% of the mass percentage of iron powder and chromium-contaminated soil powder sample. Take iron powder, mix oxalic acid, iron powder, and chromium-contaminated soil powder sample, and grind for 2 hours to obtain activated chromium-contaminated soil powder sample. Place the activated chromium-contaminated soil powder sample in the sample area of the electrolytic cell with aeration and stirring functions. Add water to the electrolytic cell according to the ratio of activated chromium-contaminated soil powder sample t...

Embodiment 2

[0038] Effect of iron powder and chromium-contaminated soil powder mass percentage on the reduction efficiency of hexavalent chromium:

[0039] Weigh the chromium-contaminated soil, grind it after drying, and pass through a 250-mesh sieve to obtain a chromium-contaminated soil powder sample. Take oxalic acid according to 6% mass percentage of oxalic acid and chromium polluted soil powder sample, iron powder and chromium polluted soil powder sample mass percentage 2.2%, 2.5%, 2.8%, 3%, 4%, 5%, 6%, 6.2%, 6.5% and 6.8% weigh iron powder, mix oxalic acid, iron powder, and chromium-contaminated soil powder, and grind for 3 hours to obtain activated chromium-contaminated soil powder. Place the activated chromium-contaminated soil powder sample in the sample area of the electrolytic cell with aeration and stirring functions. Add water to the electrolytic cell according to the ratio of activated chromium-contaminated soil powder sample to water-solid-liquid ratio of 1:1.5g / mL. The...

Embodiment 3

[0048] The effect of voltage gradient change on the reduction efficiency of hexavalent chromium:

[0049] Weigh the chromium-contaminated soil, grind it after drying, and pass through a 100-mesh sieve to obtain a chromium-contaminated soil powder sample. Take oxalic acid according to 6% mass percentage of oxalic acid and chromium polluted soil powder sample, iron powder and 6% mass percentage of chromium polluted soil powder sample weigh iron powder, mix oxalic acid, iron powder, chromium polluted soil powder sample, grind for 4 hours, Activated chromium-contaminated soil powder samples were obtained. Place the activated chromium-contaminated soil powder sample in the sample area of the electrolytic cell with aeration and stirring functions. Add water to the electrolytic cell according to the ratio of activated chromium-contaminated soil powder sample to water-solid-liquid ratio of 1:2g / mL. The electrolyzer is energized for 3 hours, and the voltage gradient is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com