A heating film system assembly for a battery pack

A heating film and assembly technology, applied in the direction of secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of heavy weight and high cost of heating film assembly, and achieve lightweight design and versatility Strong, weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

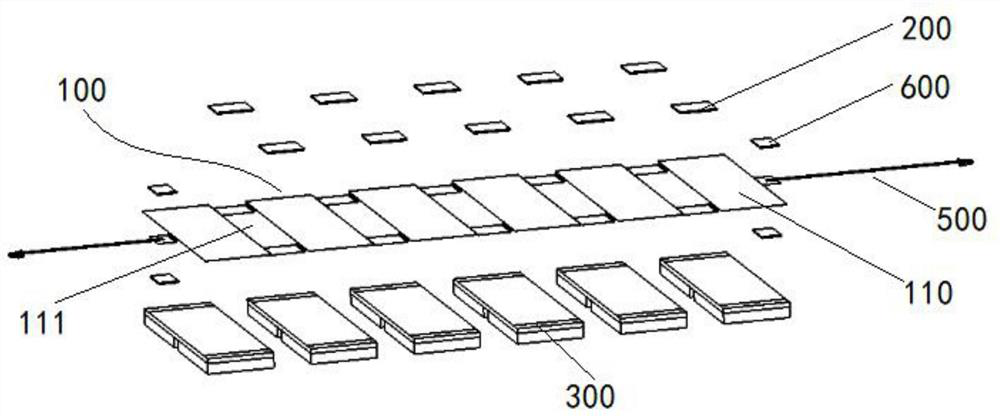

[0036] see Figure 1 to Figure 8 , the present invention provides a heating film system assembly for a battery pack. The heating film system is used to heat the heat-conducting medium through the heating film when the battery pack thermal management system is in a low-temperature environment, so as to achieve the purpose of heating the battery module 700. Features. Specifically, the heating film system assembly includes a PI heating film body 100 and an isolation foam 200, the PI heating film body 100 includes a PI film 110 and a resistance wire 120, and the PI film 110 is provided with a hollow hole 111, The hollow hole 111 separates the PI film 110 into at least two module layout areas 130, the adjacent module layout areas 130 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com