Pressure load simulating system suitable for deep-sea equipment hydraulic system and application thereof

A hydraulic system and load simulation technology, which is applied in fluid pressure actuation system components, fluid pressure actuation system testing, fluid pressure actuation devices, etc. It can solve the problem of not considering the nonlinear change of seawater pressure and the inability to simulate the hydraulic system pressure load Non-linear changes and other problems to achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

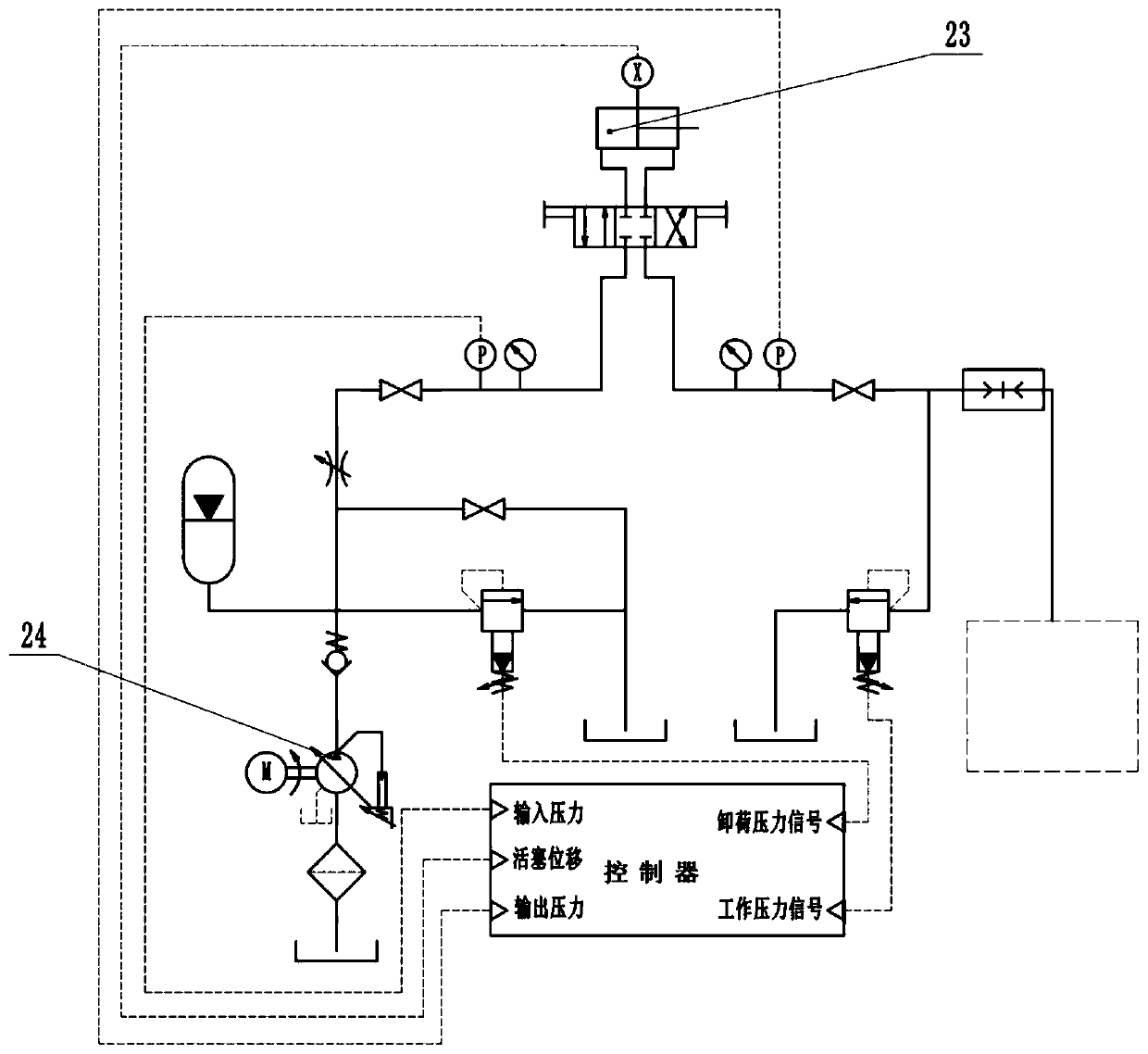

[0046] A pressure load simulation system suitable for hydraulic systems of deep sea equipment, such as figure 1 As shown, it includes piston hydraulic cylinder 1, three-position four-way reversing valve 2, working pressure gauge 3, working pressure transmitter 4, quick-change joint 5, working pressure regulating valve 7, controller 9, filter 11, First motor 12, first hydraulic pump 13, first one-way valve 14, accumulator 15, unloading valve 16, throttle valve 17, input pressure transmitter 19, input pressure gauge 20 and piston displacement sensor 22;

[0047] The first hydraulic pump 13 is connected with the first oil tank 10 through the filter 11, the first hydraulic pump 13 is connected with the first motor 12, and the first hydraulic pump 13 is respectively connected with the accumulator 15, throttling valve 14 through the first check valve 14. The valve 17, the unloading valve 16 and the first cut-off valve 8, the unloading valve 16 and the first cut-off valve 8 are all c...

Embodiment 2

[0051] A pressure load simulation system suitable for deep-sea equipment hydraulic systems, the structure is as shown in Embodiment 1, the difference is that the throttle valve 17 is an adjustable throttle valve, which can adjust the flow of hydraulic oil entering the piston hydraulic cylinder, So as to match the flow rate of the hydraulic system under test;

[0052] The three-position four-way reversing valve 2 can control the movement direction of the piston in the piston hydraulic cylinder 1, thereby controlling the hydraulic oil reserves inside the two chambers of the piston hydraulic cylinder, which is convenient for the use of the test system;

[0053] The maximum pressure of the hydraulic oil output by the first hydraulic pump 13 can reach 31.5MPa, the maximum working pressure of the accumulator 15 can reach 31.5MPa, the maximum adjustment pressure of the unloading valve 16 and the working pressure regulating valve 7 is 31.5MPa, the piston type hydraulic pressure The ma...

Embodiment 3

[0055] A pressure load simulation system suitable for hydraulic systems of deep sea equipment, such as image 3 As shown, the structure is as shown in Embodiment 2, the difference is that the piston hydraulic cylinder is a single-acting hydraulic cylinder 23, the first hydraulic pump is a pressure compensation hydraulic pump 24, and the two sides of the piston in the piston hydraulic cylinder are used to contact the hydraulic pressure. Depending on the oil area, changing the proportional relationship between the input pressure value and the output pressure value can use a smaller input pressure to obtain a larger output pressure; using the pressure compensation function of the hydraulic pump can improve the piston movement in the piston hydraulic cylinder. When the output pressure stability.

[0056] The pressurization ratio of the single-acting hydraulic cylinder 23 is 2:1-5:1, and the maximum pressure simulation of 40MPa-100MPa can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com