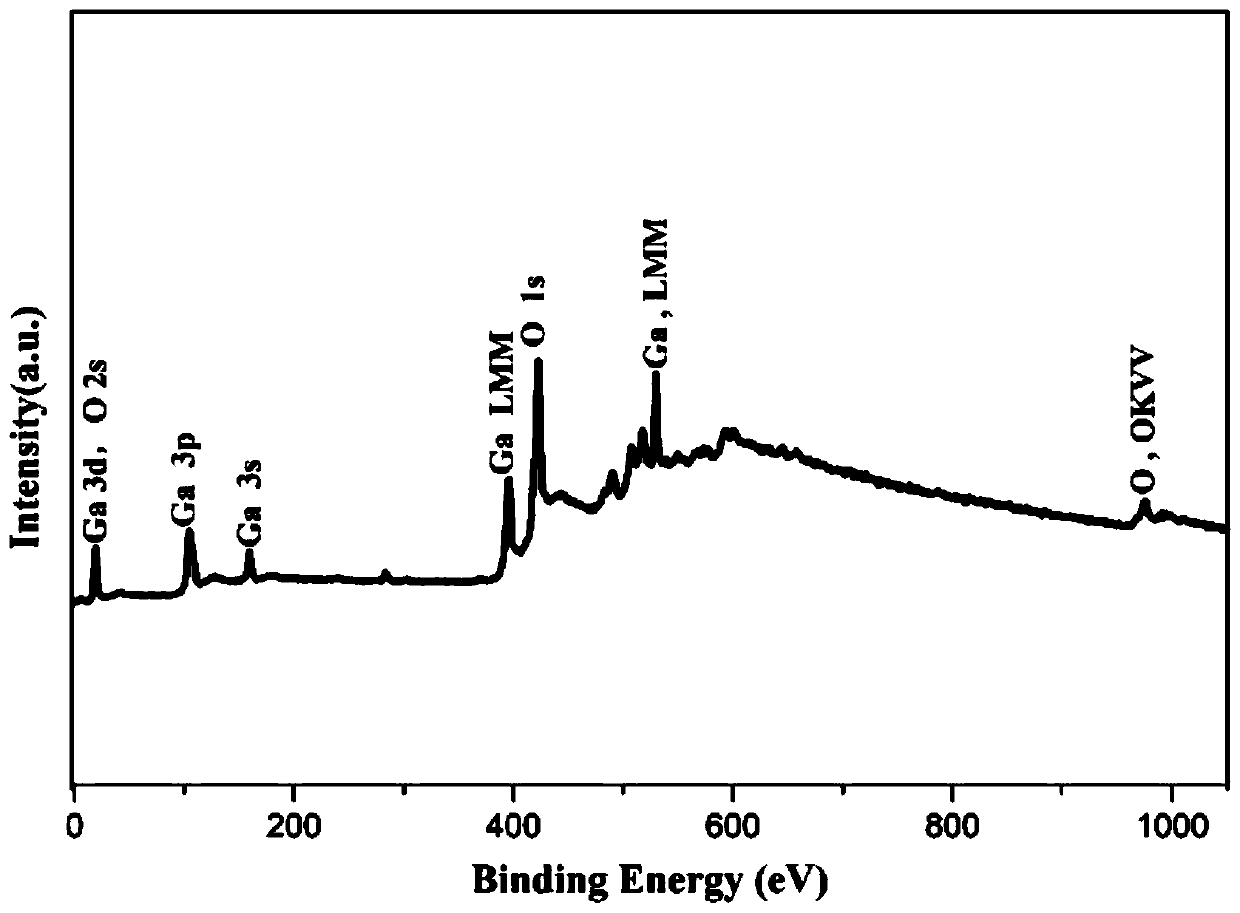

Method for preparing beta-Ga2O3 film

A -ga2o3 thin film technology, applied in the field of preparation of β-Ga2O3 thin film, can solve the problems that cannot be obtained and affect the performance of optoelectronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described more clearly and completely below in conjunction with the accompanying drawings. Any modification or equivalent replacement of the technical solution of the present invention without departing from the scope of the technical solution of the present invention shall be covered within the protection scope of the present invention.

[0024] The specific implementation steps include:

[0025] (1) Select the (0001) plane sapphire substrate; use plasma-enhanced atomic layer deposition to grow Ga on sapphire 2 o 3 For thin film, the RF plasma power is 2000W, the substrate is heated to a constant temperature of 250°C, and nitrogen is used as the carrier gas;

[0026] (2) Plasma-enhanced atomic layer deposition is as follows: ①Then pass into the TMGa source for 0.1s, and the TMGa flow rate is 200sccm; ②Then pass through the nitrogen gas for 5s; Nitrogen for 5s; ⑤Then cycle 420 cycles from step ① to step ④ and ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com