A weather-resistant resin composition and its application

A technology of resin composition and weather resistance, applied in the direction of modified epoxy resin adhesive, application, epoxy resin glue, etc., can solve the problems that cannot meet the weather resistance requirements of LED plant lighting substrates, and achieve excellent weather resistance performance, excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

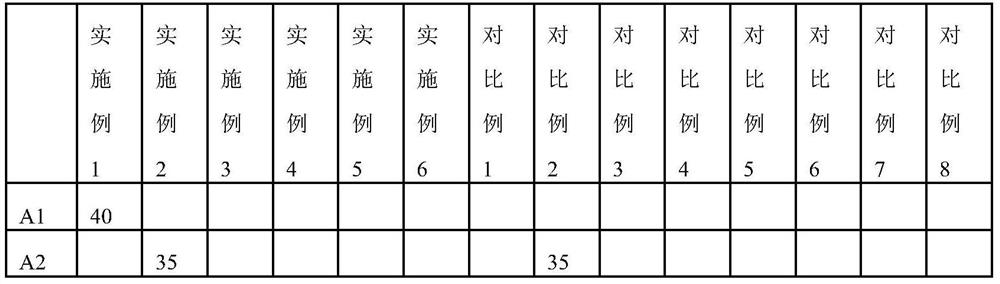

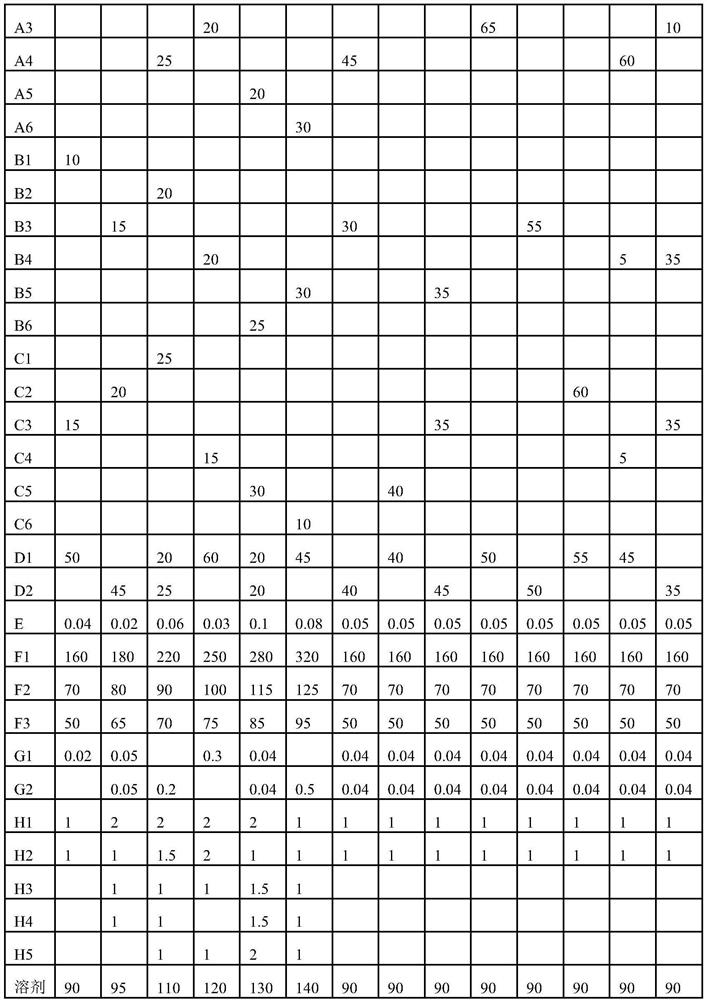

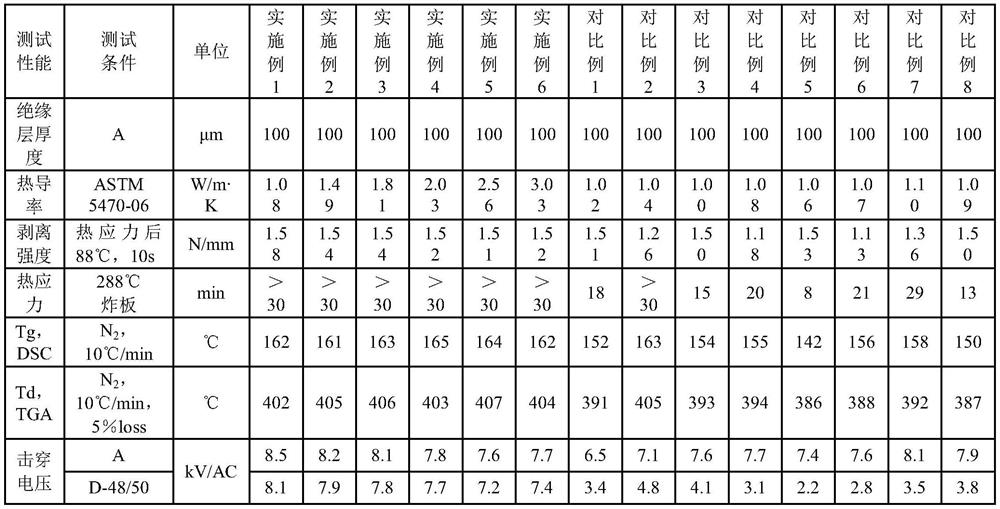

[0037] The application provides a weather-resistant resin composition, comprising the following components:

[0038] Component A: silicone hydrogenated epoxy resin;

[0039] Component B: acrylate hydrogenated epoxy resin;

[0040] Component C: alicyclic epoxy resin;

[0041] Component D: hydrogenated anhydride curing agent;

[0042] Component E: curing accelerator.

[0043] Component F: filler;

[0044] Component G: blue light absorber;

[0045] Component H: Additives.

[0046] In the present application, the components and contents of the weather-resistant resin composition are:

[0047] Component A: silicone hydrogenated epoxy resin, 20-40 parts;

[0048] Component B: acrylate hydrogenated epoxy resin, 10-30 parts;

[0049] Component C: alicyclic epoxy resin, 10-30 parts;

[0050] Component D: hydrogenated anhydride curing agent, 40-60 parts;

[0051] Component E: curing accelerator, 0.02 to 0.1 part;

[0052] Component F: filler, 280-540 parts;

[0053] Componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com