A kind of modified magnesium hydroxide, surface modification method and application

A magnesium hydroxide, surface modification technology, applied in chemical instruments and methods, dyed organosilicon compound treatment, dyed low-molecular-weight organic compound treatment, etc. problems, to achieve the effect of improving oxygen index and elongation, low production cost and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

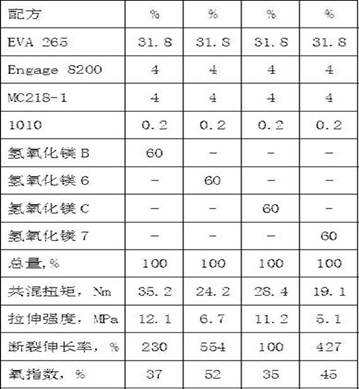

Examples

Embodiment 1

[0036] Add magnesium hydroxide raw material (chemically synthesized) into water to prepare magnesium hydroxide slurry with a solid content of 10%;

[0037] The surface modifiers added in the magnesium hydroxide slurry are: γ-(acetoxypropyl)trimethoxysilane, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- The mixture of oxide and ethanol is added to the grinding medium at the same time, and ground and reacted; in terms of mass ratio, the addition of the gamma-(acetoxypropyl) trimethoxysilane is 0.25% of magnesium hydroxide; the 9 , 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide is 0.4% of magnesium hydroxide; The ratio of the sum of phosphaphenanthrene-10-oxide and γ-(acetoxypropyl)trimethoxysilane is 50:50; the reaction time is 55 minutes; the reaction temperature is 75°C.

[0038] After the reaction is completed, the obtained modified magnesium hydroxide is separated from the grinding medium, and then filtered, dried and pulverized.

Embodiment 2

[0040] Add magnesium hydroxide raw material (chemically synthesized) into water to prepare magnesium hydroxide slurry with a solid content of 25%;

[0041] The surface modifiers added to the magnesium hydroxide slurry are: γ-(methacryloyloxy)propyltrimethoxysilane, 9,10-dihydro-9-oxa-10-phosphaphenanthrene - A mixture of 10-oxide and ethanol, adding grinding media at the same time, and grinding and reacting; in terms of mass ratio, the added amount of γ-(methacryloyloxy)propyltrimethoxysilane is that of magnesium hydroxide 0.65%; the 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide is 0.90% of magnesium hydroxide; the addition of the ethanol is the same as that of 9,10-dihydro-9 The ratio of the sum of -oxa-10-phosphaphenanthrene-10-oxide and γ-(methacryloyloxy)propyltrimethoxysilane is 55:45; the reaction time is 60min; the reaction temperature is 70°C.

[0042] After the reaction is completed, the obtained modified magnesium hydroxide is separated from the grinding mediu...

Embodiment 3

[0044] Add magnesium hydroxide raw material (chemically synthesized) into water to prepare magnesium hydroxide slurry with a solid content of 15%;

[0045] The surface modifier added in the magnesium hydroxide slurry is: a mixture of γ-(acetoxypropyl)trimethoxysilane, bis(4-carboxyphenyl)phenylphosphine oxide and ethanol, while adding grinding medium, and carry out grinding and reaction; in terms of mass ratio, the added amount of γ-(acetoxypropyl)trimethoxysilane is 1.3% of magnesium hydroxide; the bis(4-carboxyphenyl)phenyl oxidation Phosphine is 0.65% of magnesium hydroxide; the ratio of the added amount of ethanol to the sum of γ-(acetoxypropyl)trimethoxysilane and bis(4-carboxyphenyl)phenylphosphine oxide is: 53 : 47; The reaction time is 50min; The reaction temperature is 85°C.

[0046] After the reaction is completed, the obtained modified magnesium hydroxide is separated from the grinding medium, and then filtered, dried and pulverized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com