Microfluidic chip based on dielectrophoresis/electric infiltrate effect

A microfluidic chip and dielectrophoresis technology, applied in fluid controllers, laboratory containers, material analysis by electromagnetic means, etc. The effect of good scalability and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

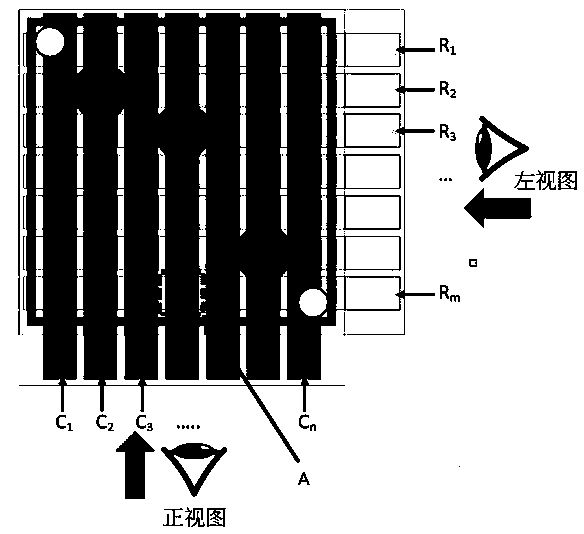

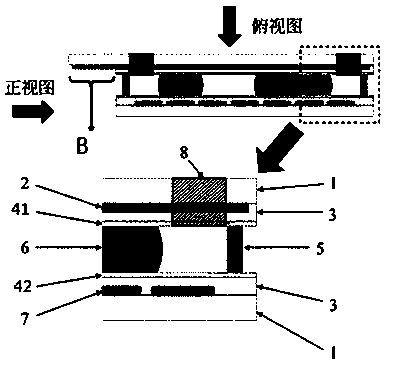

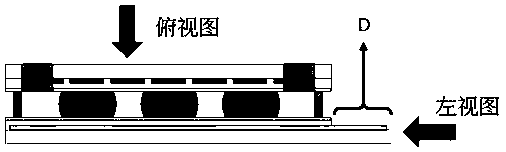

[0030] like Figure 1-3 As shown, a microfluidic chip based on the dielectrophoresis / electrowetting effect provided by the embodiment of the present invention, which is controlled by M + N microelectrodes to form an M×N microelectrode array, is characterized in that it includes a top-to-bottom Substrate layer 1, longitudinal electrode layer 2, dielectric layer 3, first hydrophobic coating layer 41, droplet layer 6, support layer 5, second hydrophobic coating layer 42, dielectric layer 3, and lateral electrode layer 7 stacked in sequence 1. Basal layer 1.

[0031] The vertical electrode layer 2 has a plurality of vertical metal lines, and each metal line is called a vertical driving electrode strip C1 , C 2 , C 3 … C n , referred to as the vertical strip; the horizontal electrode layer 7 has multiple horizontal metal lines, and each metal line is called a horizontal driving electrode strip R 1 , R 2 , R 3 … R n , referred to as horizontal bars. The electrodes in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com