Straw greening brick and preparing method thereof

A technology for greening bricks and straws, which is applied to the field of straw greening bricks and their preparation, can solve the problems of reducing greening land and straw greening bricks, etc., and achieves the effects of light hand feeling, small occupied space, and convenient transportation and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

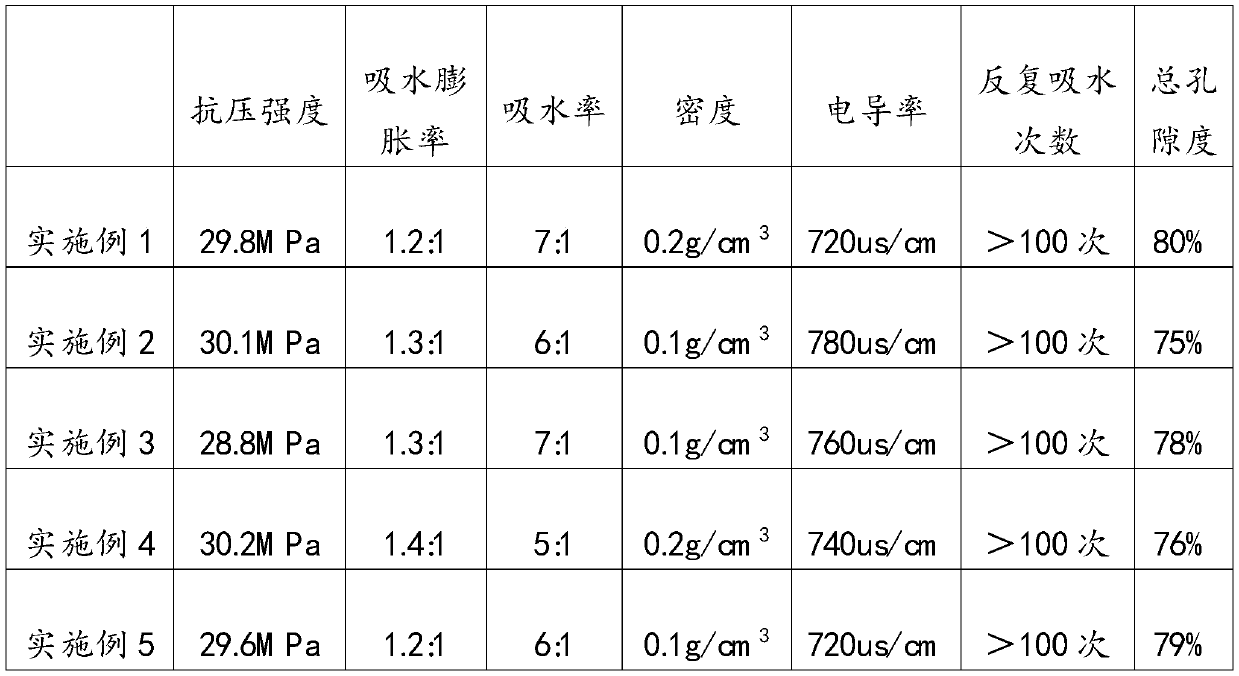

Examples

Embodiment 1

[0033]A straw greening brick, comprising the following raw materials in parts by weight: 70 kg of crop straw, 9 kg of animal manure, 4 kg of inorganic complexes, 0.8 kg of sodium polyacrylate, 0.8 kg of amino acids, 1 kg of polyamide epichlorohydrin, and 0.08 kg of ferrous sulfate kg, magnesium sulfate 0.02kg, borax 0.4kg.

[0034] The preparation method of the straw greening brick comprises the following steps:

[0035] (1) Kneading and pulverizing the crop straws, taking part of the pulverized crop straws and soaking them in KOH solution, after soaking, taking out the crop straws, neutralizing them with phosphoric acid and washing them with water in sequence to obtain materials;

[0036] (2) mixing the remaining crop stalks with animal manure and soaking in water, and further kneading and pulverizing with a straw refiner to obtain a mixed slurry;

[0037] (3) Add the mixed slurry and all the other raw materials into the material, mix and stir to obtain the base material;

...

Embodiment 2

[0040] A straw greening brick, comprising the following raw materials in parts by weight: 72kg of crop straw, 10kg of animal manure, 4kg of vermiculite, 0.9kg of sodium polyacrylate, 0.9kg of amino acid, 1kg of polyamide epichlorohydrin, 0.09kg of ferrous sulfate, Magnesium sulfate 0.02kg, borax 0.4kg.

[0041] The preparation method of the straw greening brick comprises the following steps:

[0042] (1) Knead and pulverize the crop straws, soak 20% of the pulverized crop straws in a KOH solution with a concentration of 2% for 2 hours, remove the crop straws after soaking, neutralize them with phosphoric acid, and wash them with water to obtain materials;

[0043] (2) Mix the remaining crop straw with animal manure, soak in water, and further grind and pulverize it with a straw refiner to obtain a mixed slurry with a particle size of 0.1-10 mm;

[0044] (3) Add the mixed slurry and all the other raw materials into the material, mix and stir to obtain the base material;

[00...

Embodiment 3

[0047] A straw greening brick, comprising the following raw materials in parts by weight: 73kg of crop straw, 12kg of animal manure, 5kg of inorganic complex, 1kg of sodium polyacrylate, 0.9kg of amino acid, 1kg of polyamide epichlorohydrin, and 0.09kg of ferrous sulfate , magnesium sulfate 0.02kg, borax 0.5kg.

[0048] The preparation method of the straw greening brick comprises the following steps:

[0049] (1) Knead and pulverize the crop stalks, take 25% of the pulverized crop stalks and soak them in KOH solution with a concentration of 3% for 2.2 hours. ;

[0050] (2) mixing the remaining crop stalks with animal manure and soaking in water, further grinding and pulverizing with a straw refiner to obtain a mixed slurry with a particle size of 5 mm;

[0051] (3) Add the mixed slurry and all the other raw materials into the material, mix and stir to obtain the base material;

[0052] (4) Put the base material into the mold, press with a pressure of 3MPa for 50s, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com